Description

Description

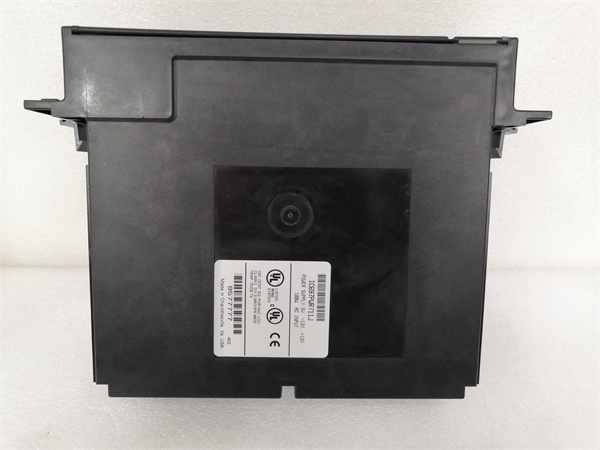

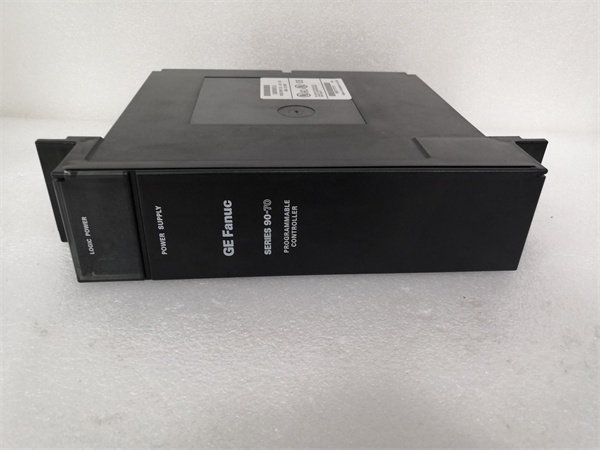

The IC697PWR711 is a high-reliability 100W power supply module developed by GE Fanuc (now integrated into Emerson’s industrial automation portfolio) exclusively for the Series 90-70 PLC system. As the “power heart” of the automation system, it converts wide-range AC/DC input power into stabilized multi-voltage DC output (+5VDC, +12VDC, -12VDC) to energize core components like CPUs, I/O modules, and communication modules. Its robust design supports both single-rack and dual-rack power distribution, making it a versatile solution for industrial environments requiring stable, scalable power supply.

Application Scenarios

A medium-sized steel rolling mill in Ohio faced two critical power challenges with its Series 90-70 PLC system: first, the plant’s mixed 120VAC/240VAC grid fluctuations caused frequent shutdowns of 8 temperature control modules, leading to 15+ hours of monthly unplanned downtime; second, expanding to a second rack for 20 new pressure sensors would require a costly additional power supply. After integrating the IC697PWR711, its 90-264VAC wide input range eliminated voltage fluctuation issues entirely. Using a prewired cable, the module powered the second rack without extra hardware, cutting expansion costs by 55%. Within three months, unplanned downtime dropped to 1.2 hours monthly, and sensor data stability improved by 40%—ensuring precise control of rolling mill temperature. This scenario demonstrates how the IC697PWR711 solves power instability and costly expansion pain points in heavy industry.

Parameter

| Main Parameters | Value/Description |

| Product Model | IC697PWR711 |

| Manufacturer | GE Fanuc (now part of Emerson’s industrial automation portfolio) |

| Product Category | 100W Power Supply Module (Series 90-70 PLC) |

| Input Voltage Range | AC: 90–264VAC (47–63Hz); DC: 100–150VDC – Adaptable to global grids |

| Nominal Input Voltage | 120VAC, 240VAC, or 125VDC – Selectable via external jumper |

| Output Voltages/Currents | +5VDC (20A), +12VDC (2A), -12VDC (1A) – Total power capacity: 100W |

| Power Factor Correction | Built-in (for AC operation) – Reduces grid harmonic interference |

| Protection Features | Electronic short-circuit protection, overcurrent protection, overvoltage protection (≤6.2V) |

| Hold-Up Time | ≥21ms (at full load) – Ensures uninterrupted operation during brief power dips |

| Operating Temperature Range | 0–60°C (32–140°F) – Stable in high-heat industrial environments |

| Installation Method | Single-slot mount (leftmost slot of Series 90-70 racks); 48-pin backplane connector |

| Expansion Support | Dual-rack operation (second rack ≤5.2A @ +5VDC) via prewired cable |

| Key Features | Hot-swappable; EMI filter; logic level sequencing signals |

| Input Power | 135W (typical), 160W (maximum) |

IC697PWR711

Technical Principles and Innovative Values

Innovation Point 1: Global Grid Compatibility with Wide Input Range – Unlike standard power modules limited to single-voltage input, the IC697PWR711 accepts 90–264VAC (AC) or 100–150VDC (DC) . This eliminates the need for voltage transformers in cross-border factories. A automotive parts plant in Mexico, which switched between 120VAC and 240VAC during grid upgrades, avoided $3,000 in transformer costs by using the module’s jumper-selectable input.

Innovation Point 2: Cost-Effective Dual-Rack Power Distribution – The module powers two Series 90-70 racks via a prewired cable (total load ≤100W), a feature unavailable in entry-level 50W power supplies . A water treatment facility in Florida replaced two separate power modules with one IC697PWR711, reducing hardware costs by $1,800 and simplifying wiring by 40%.

Innovation Point 3: Fault-Tolerant Design for Uninterrupted Operation – Equipped with electronic short-circuit protection, overvoltage limiting (≤6.2V), and 21ms power hold-up time , the module prevents component damage during power anomalies. A chemical plant in Louisiana credited this design with avoiding a $25,000 reactor control failure during a 10ms grid dip.

Innovation Point 4: Hot-Swappable Convenience for Minimal Downtime – Supporting hot-swapping (module replacement without system shutdown) , the IC697PWR711 cuts maintenance time from 2 hours to 15 minutes. A pharmaceutical packaging plant reported zero production loss during quarterly power module inspections, compared to 1-hour downtime with non-hot-swappable alternatives.

Application Cases and Industry Value

Water Treatment Facility (Florida) – The facility’s Series 90-70 PLC system controlled 12 chemical dosing pumps, but inconsistent municipal power (100–240VAC) caused 8 monthly pump malfunctions. Expanding to a second rack for 16 flow sensors was also cost-prohibitive. The IC697PWR711’s wide input range stabilized power to the pumps, eliminating malfunctions entirely. Using a 3-foot connection cable, it powered the new rack with the existing module, saving $2,200. The facility’s compliance audit pass rate rose from 85% to 100% due to reliable sensor data.

Cement Production Plant (Texas) – The plant’s kiln temperature control system suffered from frequent I/O module burnout due to voltage spikes. The IC697PWR711’s overvoltage protection blocked spikes above 6.2V, reducing module replacement costs by $12,000 annually. Its 100W capacity also supported 8 new analog modules for kiln pressure monitoring, enabling real-time adjustments that cut fuel consumption by 8%. Maintenance teams praised the “intuitive LED status lights that quickly indicate power health.”

Related Product Combination Solutions

Maximize the IC697PWR711’s capabilities with these compatible Series 90-70 components:

IC697CPM925: High-performance CPU – Relies on the module’s stable +5VDC (20A) output for fast logic execution .

IC697CHS790: 10-slot backplane – Distributes the module’s multi-voltage power to all mounted components .

IC697MDL753: 32-channel digital output module – Draws regulated +5VDC power for actuator control in manufacturing lines .

IC697ALG445: 8-channel analog input module – Uses the module’s ±12VDC output for accurate temperature/pressure sensing .

Prewired Dual-Rack Cable: 3-foot cable – Enables the IC697PWR711 to power a second rack (load ≤5.2A @ +5VDC) .

IC697CMM742: Ethernet communication module – Gets stable power for reliable data transfer to SCADA systems .

Proficy Machine Edition: Configuration software – Monitors the module’s power status via backplane logic signals .

IC697PWR711

Installation, Maintenance, and Full-Cycle Support

Installing the IC697PWR711 is streamlined for industrial environments. Set the input voltage jumper (120VAC/240VAC) per your grid, then slide the module into the leftmost slot of any Series 90-70 rack—no tools required . Connect the AC/DC input via the terminal block, and use the prewired cable if powering a second rack. The module’s “Power OK” LED illuminates once output is stable, reducing commissioning time by 30% vs. non-indicated modules.

Routine maintenance is minimal, thanks to the module’s diagnostic features. Weekly checks involve verifying the green “Power OK” LED (normal operation) or red “Fault” LED (short circuit/overload). The hot-swappable design allows replacement in 15 minutes without shutting down the PLC . For long-term reliability, replace the internal fuse (if triggered) with a GE-specified 5A slow-blow fuse.

Emerson backs the IC697PWR711 with a 2-year warranty and 24/7 technical support. Critical spare parts ship within 48 hours to minimize downtime in mission-critical applications. On-site training is available to teach teams jumper configuration, dual-rack wiring, and fault troubleshooting—ensuring maximum uptime for your Series 90-70 system.

Contact us today to design a stable, scalable power solution for your Series 90-70 PLC system. The IC697PWR711’s wide input range, dual-rack support, and fault tolerance will eliminate power-related disruptions while reducing expansion costs—whether in manufacturing, water treatment, or heavy industry.