Description

Product Overview

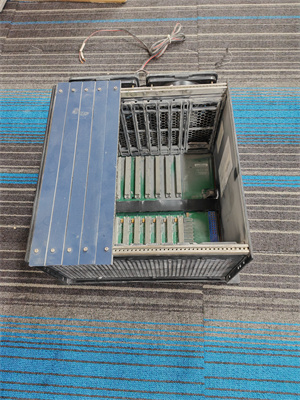

The GE IC698CHS009A is a pivotal 9 – slot I/O rack within GE’s Rx7i PACsystem series, crafted to meet the diverse demands of industrial control systems. As a central housing unit, it plays a fundamental role in providing a stable and organized platform for integrating various control modules. This rack is designed with compatibility in mind, being fully compatible with all Rx7i CPU and I/O devices, as well as 90 – 70 series I/O and VME modules. It serves as the backbone of an automation system, enabling seamless communication and coordination between different components.

The GE IC698CHS009A features slot sensing technology, which is a game – changer in simplifying the configuration process. This function allows for software – based configuration, eliminating the need for traditional DIP switches or jumpers for I/O addressing. This not only reduces the complexity of setup but also minimizes the chances of human – error during installation. Additionally, it offers automatic daisy – chaining of interrupt confirmation and bus authorization signals, further streamlining the operation and enhancing the overall system efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC698CHS009A |

| Manufacturer | GE |

| Product Type | 9 – slot I/O Rack |

| Number of Slots | 9 |

| Operating Voltage | 5 – 12 Volts DC |

| Current Rating | 20 Amps (with 100 Watts Power)/60 Amps (with 350 Watts Power) |

| Compatibility | Rx7i CPU, I/O devices, 90 – 70 series I/O, VME modules |

| Communication Protocols | Supports SRTP and Modbus TCP/IP (through integrated Ethernet, not specified if built – in or via module) |

| Operating Temperature | – 20 °C to + 60 °C |

| Storage Temperature | – 40 °C to + 85 °C |

| Humidity | 5% – 95% non – condensing |

| Dimensions (H x W x D) | 283 x 320 x 190 mm (approximate, as per some sources; may vary slightly) |

| Mounting Type | Rear – mount, standard 19 – inch rack – mount compatible |

| Material | Aluminum chassis for durability |

IC698CHS009A

Main Features and Advantages

Slot Sensing and Easy Configuration

The GE IC698CHS009A‘s slot sensing feature revolutionizes module installation. Without the need for DIP switches or jumpers for I/O addressing, users can simply rely on software configuration. This simplicity reduces the time spent on setup and debugging, making it easier for technicians to integrate new modules or expand existing systems. For example, when adding a new I/O module to an industrial control setup, the system can automatically detect and configure the module, eliminating the need to manually set complex addressing settings.

Automatic Daisy – Chaining

The automatic daisy – chaining of interrupt confirmation and bus authorization signals is a significant advantage. By eliminating the need for slot jumpers, it reduces the risk of misconfiguration and improves the reliability of signal transmission. In a large – scale industrial automation system with multiple modules, this feature ensures that interrupts are handled efficiently, and bus access is smoothly coordinated, leading to more stable system operation.

Wide Compatibility

This I/O rack’s compatibility with a broad range of components, including Rx7i CPUs, I/O devices, 90 – 70 series I/O, and VME modules, makes it extremely versatile. It can be used in various industrial settings, whether upgrading an existing 90 – 70 series system or building a new Rx7i – based control system. This compatibility also allows for easy integration of different types of modules, such as communication modules, power supplies, and specialized I/O modules, providing a comprehensive solution for diverse control requirements.

Durable Construction

With an aluminum chassis, the GE IC698CHS009A is built to withstand harsh industrial environments. Aluminum offers high durability and resistance to corrosion, ensuring that the rack can operate reliably in dusty, humid, or chemically – aggressive settings. This robust construction not only extends the lifespan of the rack but also protects the sensitive modules housed within it, contributing to the overall reliability of the industrial control system.

IC698CHS009A

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC698CHS009A is extensively used to manage production lines. It can house the necessary CPUs, I/O modules, and communication modules to control robotic arms, conveyor belts, and automated assembly machines. For instance, in an automotive manufacturing plant, it can power the control system that coordinates the movement of robotic arms for precision welding and part assembly. The rack’s ability to handle multiple modules and its reliable communication capabilities ensure seamless operation, reducing production downtime and improving product quality.

Energy Sector

In power generation facilities, whether it’s a coal – fired power plant, a wind farm, or a hydroelectric power station, the GE IC698CHS009A plays a crucial role. It can be used to build control systems that monitor and manage the power generation process. For example, in a wind farm, the rack can hold the modules that control the pitch and yaw of wind turbines, ensuring optimal energy capture. In a power distribution network, it can support the control system that manages the switching and protection of electrical circuits, maintaining grid stability.

Transportation

Within the transportation industry, particularly in intelligent transportation systems, the GE IC698CHS009A is utilized. It can be part of the control system for traffic management centers, where it houses modules for data acquisition from sensors, communication with traffic lights, and processing of traffic flow data. In a subway system, it can control the operation of escalators, elevators, and train doors, ensuring safe and efficient passenger movement. The rack’s reliability and compatibility make it suitable for these mission – critical applications in transportation.

Related Products

IC698CHS117

This is another I/O rack from GE, likely with different slot configurations or enhanced features compared to the GE IC698CHS009A. It may offer more slots or improved power distribution capabilities, making it suitable for larger – scale industrial control systems that require additional module integration.

IC698ACC735

An accessory or component that can be used in conjunction with the GE IC698CHS009A. It might provide additional functionality, such as enhanced communication capabilities, signal conditioning, or power management features for the modules installed in the I/O rack.

IC698CMX016

Could be a communication – related module that can be installed in the GE IC698CHS009A rack. It may offer different communication protocols or higher – speed data transfer capabilities, enabling better connectivity with other devices in the industrial network.

IC698PSA100

A power supply module designed for use with the Rx7i series, which can be installed in the GE IC698CHS009A rack. It likely provides a specific power output to meet the energy requirements of the modules housed in the rack, ensuring stable operation.

IC698CRE020

This could be a cooling – related component, such as a fan or heat sink module, that can be added to the GE IC698CHS009A to enhance its cooling capabilities. In industrial environments where heat generation can be a concern, this component helps maintain optimal operating temperatures for the modules.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC698CHS009A, ensure that the installation area is clean and free from dust, debris, and excessive moisture. Check the power supply to confirm that it meets the 5 – 12 Volts DC requirement. Verify the compatibility of the modules that will be installed in the rack with the GE IC698CHS009A. Measure the available space to ensure a proper fit, considering its dimensions of approximately 283 x 320 x 190 mm. When handling the rack, use appropriate electrostatic discharge (ESD) protection to prevent damage to its sensitive components.

Maintenance recommendations: Regularly inspect the GE IC698CHS009A for any signs of physical damage, such as cracks in the aluminum chassis or loose connections. Check the status of the modules installed in the rack to ensure they are operating correctly. Clean the rack and its modules gently using a soft, dry cloth to remove dust, which can affect heat dissipation and performance. Monitor the operating temperature and humidity of the environment to ensure they remain within the specified – 20 °C to + 60 °C temperature range and 5% – 95% non – condensing humidity levels. If any issues are detected, refer to the product manual for detailed troubleshooting steps.

Maintenance recommendations: Regularly inspect the GE IC698CHS009A for any signs of physical damage, such as cracks in the aluminum chassis or loose connections. Check the status of the modules installed in the rack to ensure they are operating correctly. Clean the rack and its modules gently using a soft, dry cloth to remove dust, which can affect heat dissipation and performance. Monitor the operating temperature and humidity of the environment to ensure they remain within the specified – 20 °C to + 60 °C temperature range and 5% – 95% non – condensing humidity levels. If any issues are detected, refer to the product manual for detailed troubleshooting steps.

Product Guarantee

GE stands firmly behind the quality of the GE IC698CHS009A. The product undergoes rigorous quality control procedures during manufacturing to ensure its reliability and performance. GE offers a standard one – year warranty for the GE IC698CHS009A. In the unlikely event that the rack develops defects in materials or workmanship during this period, GE will provide prompt repair or replacement services. Their dedicated after – sales service team is available to assist customers with any questions regarding installation, operation, or maintenance. GE’s technical experts can offer remote or on – site support, depending on the customer’s needs, to ensure that the GE IC698CHS009A continues to function optimally in industrial automation applications, giving customers confidence in their investment.