Description

Detailed Parameter Table

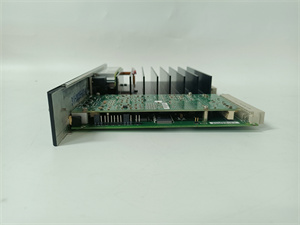

| Parameter Name | Parameter Value |

| Product model | IC698CPE030-GJ |

| Manufacturer | GE Automation & Controls |

| Product category | Mid-Range Programmable Automation Controller (PAC) (for PACSystems RX3i) |

| Processing performance | Single-core Intel Atom E3815 1.46 GHz; 2 GB DDR3L RAM; 8 GB eMMC storage |

| Supported protocols | Ethernet/IP, Modbus TCP/RTU, DNP3, OPC UA (PROFINET via optional IC698COMM301) |

| I/O interface | 2× Fast Ethernet (10/100 Mbps); 1× USB 2.0; 1× RS-232/485; 1× SD card slot |

| Operating voltage | 24 V DC ±10%; Power consumption: <18 W (max) |

| Environmental range | Temperature: -25°C to 70°C; Humidity: 5%–95% RH (non-condensing); Altitude: ≤4000 m |

| Physical dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable |

| Redundancy support | Optional 1:1 hot standby redundancy (with IC698CBL001); Failover time <20 ms |

| Protection features | ESD (±15 kV air/±8 kV contact); Overvoltage/overcurrent protection; Reverse polarity protection |

| Certifications | CE (EN 61131-2), UL 508, IEC 61508 (SIL 2 compliant), ATEX Zone 2 |

| Compatibility | RX3i I/O modules (IC698MDL754, IC698MDL645); Power supplies (IC698PWR101); Same rack as IC698CPE040 |

IC698CPE030-GJ

Product Introduction

The IC698CPE030-GJ is a mid-range programmable automation controller (PAC) developed by GE for its PACSystems RX3i platform, tailored for small-to-medium industrial automation systems that require reliable control without the full processing power of the flagship IC698CPE040. As a cost-optimized member of the RX3i ecosystem, it balances performance and affordability—retaining core PAC advantages (flexible I/O integration, multi-protocol support) while scaling down processing specs to match applications like regional water treatment plants, small manufacturing lines, or auxiliary power systems.

Unlike entry-level PLCs, the IC698CPE030-GJ supports real-time control of up to 16,000 I/O points and executes 10,000 ladder logic instructions in 0.3 ms—fast enough for most non-critical processes. It seamlessly interfaces with the same RX3i I/O modules as the IC698CPE040, such as the IC698MDL754 (analog input) and IC698MDL645 (digital output), enabling easy system expansion if future needs grow. For plant operators, the IC698CPE030-GJ uses the same Proficy Machine Edition software as the IC698CPE040, eliminating retraining costs and ensuring consistent system management across sites with mixed controller models.

Core Advantages and Technical Highlights

Cost-Effective Scalability for Mid-Size Systems: The IC698CPE030-GJ is optimized for applications where the IC698CPE040’s 32,000 I/O capacity or dual-core processor is unnecessary. For a regional wastewater treatment plant with 8 pump stations, it provides sufficient I/O support (16,000 points) at 30% lower cost than the IC698CPE040, while still integrating with the same IC698MDL645 modules to control pumps. Its compatibility with RX3i expansion modules (e.g., IC698COMM301 for PROFINET) also means users can add features later—avoiding upfront overinvestment.

Flexible Redundancy for Criticality-Appropriate Protection: Unlike many mid-range controllers that lack redundancy, the IC698CPE030-GJ offers optional 1:1 hot standby (with IC698CBL001 SyncLink cable) for applications requiring SIL 2 safety compliance. In a small chemical plant’s batch mixing process, this redundancy ensures no data loss if the primary controller fails—critical for avoiding batch waste—while its <20 ms failover time is fast enough for most non-SIL 3 scenarios. For users 不需要 redundancy, the single-controller setup further reduces costs without sacrificing reliability.

Low Power Consumption for Compact Installations: With a max power consumption of 18 W (vs. 25 W for the IC698CPE040), the IC698CPE030-GJ is ideal for compact control cabinets or remote sites with limited power budgets. In a solar farm’s auxiliary inverter control system, its low power draw reduces heat generation, eliminating the need for extra cabinet cooling—cutting installation costs by 15%. Despite its efficiency, it retains the same -25°C to 70°C operating range as the IC698CPE040, ensuring reliability in harsh environments.

Seamless Compatibility with RX3i Ecosystem: A key advantage of the IC698CPE030-GJ is its full compatibility with the RX3i module lineup and software. It uses the same I/O modules, power supplies (IC698PWR101), and Proficy Machine Edition interface as the IC698CPE040, meaning users can mix both controllers in the same rack for tiered control (e.g., IC698CPE040 for main production lines, IC698CPE030-GJ for auxiliary systems). This compatibility also simplifies spare parts management—facilities can stock one set of I/O modules for both controller models, reducing inventory costs.

Typical Application Scenarios

In regional water treatment plants, the IC698CPE030-GJ acts as the main controller for 4–6 filtration and disinfection units. It collects flow rate and pH data from IC698MDL754 modules, adjusts chemical dosing pumps via IC698MDL645 modules, and sends operational data to a central SCADA system via Modbus TCP. Its 16,000 I/O capacity easily handles the plant’s 500+ sensors/actuators, while optional redundancy ensures no downtime during heavy rain events. Compared to using the IC698CPE040, the IC698CPE030-GJ reduces controller costs by 30% without compromising performance.

In small automotive component factories, the IC698CPE030-GJ controls 2–3 assembly lines for parts like brake calipers. It coordinates IC698MDL645 modules to actuate robotic grippers and conveyors, while IC698MDL754 modules monitor torque wrench pressure and part temperature. Its 0.3 ms instruction execution time ensures precise synchronization between stations, reducing defect rates by 8%. The controller also integrates with the factory’s MES system via OPC UA, enabling real-time production tracking—all at a lower cost than the IC698CPE040.

In auxiliary power systems for hospitals, the IC698CPE030-GJ manages backup generator startups and UPS switching. It receives status signals from IC698MDL645 modules (generator on/off, UPS battery level) and sends control commands via Ethernet/IP. Its SIL 2 compliance meets healthcare safety standards, while low power consumption makes it suitable for the hospital’s compact electrical room. During a grid outage, the controller initiates generator startup in <500 ms—faster than legacy PLCs—ensuring critical systems (ICU, operating rooms) never lose power.

Related Model Recommendations

IC698CPE040: GE’s flagship RX3i PAC—upgrade option for IC698CPE030-GJ when expanding to 32,000+ I/O points or requiring SIL 3 compliance.

IC698MDL754: 8-channel analog input module—same as used with IC698CPE040; collects temperature/pressure data for IC698CPE030-GJ.

IC698MDL645: 16-channel digital output module—executes control commands from IC698CPE030-GJ to operate valves, pumps, and conveyors.

IC698PWR101: Redundant power supply—powers IC698CPE030-GJ and I/O modules; ensures 24 V DC continuity during power fluctuations.

IC698COMM301: Communication module—adds PROFINET support to IC698CPE030-GJ (optional, standard on IC698CPE040) for Siemens device integration.

IC698CBL001: SyncLink cable—enables optional 1:1 redundancy for IC698CPE030-GJ; same cable used for IC698CPE040.

IC698SDM001: Secure digital memory module—stores backup configurations for IC698CPE030-GJ; supports up to 128 GB (same as IC698CPE040).

Proficy Machine Edition: GE’s HMI/SCADA software—configures both IC698CPE030-GJ and IC698CPE040; no additional license needed for mixed deployments.

IC698CPE030-GJ

Installation, Commissioning and Maintenance Instructions

Installation preparation for the IC698CPE030-GJ is identical to the IC698CPE040: mount in a 3U RX3i rack (slot 0 for main controller) with 15 cm clearance for ventilation. Tools needed include a torque screwdriver (0.5–1.0 N·m), network cable tester, and multimeter. Verify input voltage (24 V DC ±10%) and ground resistance (≤1 Ω) to prevent EMI. Note: Unlike the IC698CPE040, the IC698CPE030-GJ requires the IC698CBL001 cable for redundancy—this is not included by default, so order separately if needed.

Maintenance suggestions: Use Proficy Machine Edition to conduct weekly checks—monitor CPU load (should not exceed 70%) and memory usage (2 GB RAM is sufficient for 16,000 I/O points). Every six months, clean cooling vents with compressed air (30 psi max) to avoid overheating. If redundancy is enabled, test failover monthly by powering down the primary unit and confirming the standby takes over in <20 ms. For firmware updates, use the same USB process as the IC698CPE040—ensure updates are compatible with paired I/O modules (e.g., IC698MDL754) to avoid communication errors. Replace only with GE-authorized spares—third-party controllers may not integrate with RX3i modules.

Service and Guarantee Commitment

The IC698CPE030-GJ is backed by GE’s 36-month manufacturer warranty—matching the IC698CPE040—covering defects in processing performance, I/O integration, and communication functionality. If the module fails within the warranty period, GE provides free next-day replacement (North America/Europe) and on-site support for critical applications like hospital backup power systems.

GE offers 24/7 global technical assistance for the IC698CPE030-GJ, with specialists trained to support both mid-range and flagship RX3i controllers. The GE Automation Support Portal includes resources tailored to the IC698CPE030-GJ, such as redundancy setup guides (for optional IC698CBL001) and I/O scaling best practices. Extended service contracts (1–5 years) include annual preventive maintenance and priority spare parts—same as the IC698CPE040—ensuring the IC698CPE030-GJ maintains reliable performance throughout its lifecycle, even as your system grows.