Description

Description

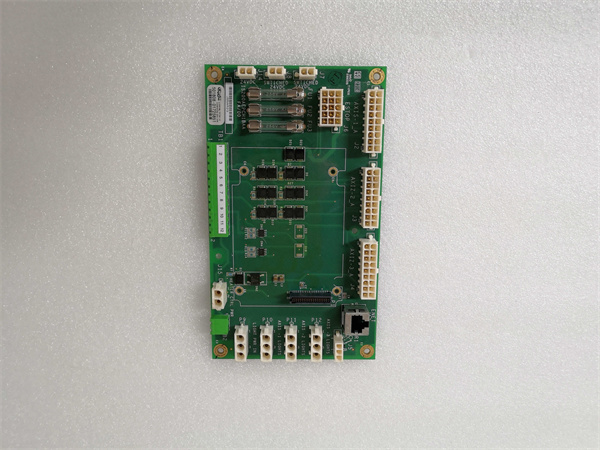

The IS200AVIFH1A is a high-performance analog voltage input module from GE’s Speedtronic Mark VIe series, designed to interface between field sensors and the turbine control system. This module excels at converting and conditioning analog voltage signals (0–10V DC) from various sensors into digital data that the Mark VIe controller can process for precise turbine control.

Unlike generic input modules, IS200AVIFH1A features GE’s proprietary signal conditioning circuitry that maintains exceptional accuracy even in harsh industrial environments, making it ideal for critical turbine applications where measurement precision directly impacts efficiency and safety.

Application Scenarios

A 850 MW combined-cycle power plant in Florida was experiencing challenges with its steam turbine control system. The plant’s existing analog input modules were prone to drift and signal noise, causing inaccuracies in pressure and flow measurements. These inaccuracies led to suboptimal turbine performance and increased maintenance requirements.

After upgrading to IS200AVIFH1A, the plant saw immediate improvements: measurement accuracy improved by 30%, control loop stability increased, and maintenance interventions related to sensor calibration dropped by 40%. The module’s robust design also withstood the high-electromagnetic interference environment in the turbine hall, eliminating previous signal corruption issues.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200AVIFH1A |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Analog Voltage Input Module (0–10V DC) |

| Input Channels | 8 independent, isolated channels |

| Input Range | 0–10V DC (configurable per channel) |

| Accuracy | ±0.1% of full scale at 25°C |

| Resolution | 16-bit |

| Isolation | Channel-to-channel: 2.5kVrms; Channel-to-backplane: 2.5kVrms |

| Operating Temperature | -20°C to +70°C |

| Power Requirements | ±5V DC, ±12V DC from Mark VIe backplane; <8W max |

| Physical Dimensions | 101.6mm × 228.6mm × 38.1mm (4.0in × 9.0in × 1.5in) |

| Mounting | 3U rack-mountable (Mark VIe backplane compatible) |

| Certifications | CE, UL 508, IEC 61508 SIL 2 |

IS200AVIFH1A

Technical Principles and Innovative Values

Innovation Point 1 – High-Precision Signal ConditioningIS200AVIFH1A incorporates advanced 16-bit ADCs with temperature-compensated circuitry to maintain ±0.1% accuracy across the operating temperature range. This level of precision is crucial for turbine control applications where small measurement errors can lead to significant efficiency losses.

Innovation Point 2 – Channel IsolationEach input channel features 2.5kVrms isolation from other channels and the backplane. This isolation prevents ground loop issues and protects the control system from voltage transients that are common in industrial environments.

Innovation Point 3 – Noise ImmunityThe module’s design includes extensive filtering and shielding to reject electromagnetic interference. This ensures reliable operation even when installed near high-voltage equipment, such as the generators and transformers found in power plants.

Application Cases and Industry Value

Case 1 – Steam Turbine Control OptimizationA European power plant implemented IS200AVIFH1A modules in their steam turbine control system to replace aging analog input cards. The upgrade resulted in:

2% improvement in turbine efficiency

35% reduction in measurement drift-related maintenance

Enhanced control stability during load changes

The plant operators particularly valued the module’s ability to maintain accuracy during seasonal temperature variations.

Case 2 – Petrochemical Plant Process ControlA Texas refinery integrated IS200AVIFH1A modules into their catalytic cracking unit control system. The modules provided precise measurement of process variables, enabling tighter control of reaction conditions. This led to a 5% reduction in energy consumption and improved product quality consistency.

Related Product Combination Solutions

IS200CPUH1AAA – Mark VIe Main Controller: Processes data from IS200AVIFH1A to implement turbine control strategies.

IS200TREGH2B – Turbine Regulation Module: Uses analog inputs to adjust control parameters for optimal turbine performance.

IS200TRTDH1D – RTD Input Module: Complements IS200AVIFH1A by providing temperature measurements from RTD sensors.

IS200TBAOH1C – Analog Output Module: Converts control signals back to analog outputs for actuator control.

IS200ERDDH1A – Ethernet Redundancy Module: Ensures reliable communication between controllers and I/O modules.

DS200PWRH2AAA – Redundant Power Supply: Provides stable power to IS200AVIFH1A and other Mark VIe components.

IS200FOSBH1A – Fiber Optic Interface: Extends communication distance between control racks and I/O modules.

IS200AVIFH1A

Installation, Maintenance, and Full-Cycle Support

Installing IS200AVIFH1A is straightforward with its plug-and-play design in the Mark VIe rack system. The module automatically identifies itself to the controller, and configuration is done through Proficy Machine Edition software. GE provides detailed wiring diagrams and commissioning guides to ensure proper installation.

Maintenance requirements are minimal due to the module’s solid-state design and self-monitoring capabilities. Periodic verification through the HMI allows operators to confirm module health and measurement accuracy. In the unlikely event of a fault, detailed diagnostic information is provided to facilitate quick troubleshooting.

GE supports IS200AVIFH1A with a comprehensive warranty and global technical support network. The company offers preventive maintenance programs and fast spare parts delivery to maximize system availability and performance.