Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200BICHH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Precision Current Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Acquires, conditions, and converts 4-20 mA current-loop signals to digital data; transmits to Mark VIe CPU for real-time control |

| Input channel quantity | 16 differential channels (independently configurable) |

| Input signal type | 4-20 mA DC (primary); 0-20 mA DC (software-selectable per channel); supports 2-wire/4-wire sensor compatibility |

| Resolution | 18-bit ADC (262,144 discrete levels) – 4x higher precision than 16-bit alternatives |

| Accuracy | ±0.02% of full scale (at 25°C); ±0.05% over operating temperature range |

| Sampling rate | 200 samples per second (SPS) per channel – captures dynamic current fluctuations |

| Isolation rating | Channel-to-channel: 2.5 kV RMS; Input-to-backplane: 5 kV RMS – eliminates ground loops |

| Noise suppression | 4th-order low-pass filter (cutoff: 1-100 Hz, software-adjustable); 50/60 Hz notch filter (auto-sensing) |

| Communication interface | Mark VIe backplane (1 Gbps redundant bus); supports IEC 61850 protocol for substation integration |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F); no derating up to 75 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.7 A; provides 24 V DC excitation for 2-wire sensors (max 200 mA total) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 4,800,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 5.1 cm (D) (6.5 in × 5.0 in × 2.0 in) |

| Weight | 0.72 kg (1.59 lbs) |

| Compatibility | Mark VIe Series B/C/D controllers; IS200CABPG1B/IS200CABPG2B backplanes; pairs with IS200CPFXG1A (power supply) / IS200JGNDG1A (grounding) |

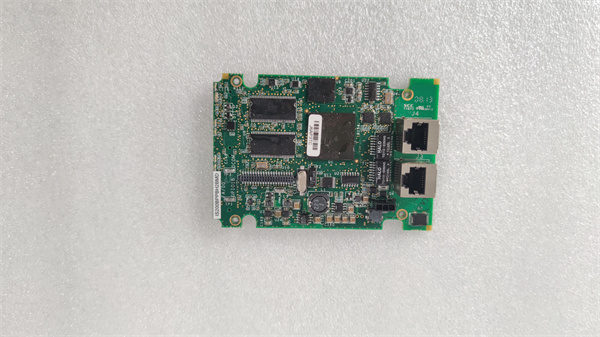

IS200BICHH1A

Product Introduction

The IS200BICHH1A is a high-precision current input module engineered by GE for its Mark VIe Speedtronic control system—designed to be the “current-signal precision hub” for critical turbine parameters monitored via 4-20 mA current loops (e.g., fuel flow, steam pressure, lube oil pressure). Unlike general-purpose analog modules (like IS200BAIAH1B, which handles both voltage and current), IS200BICHH1A is optimized exclusively for current signals: its 18-bit ADC and dedicated noise filters deliver unmatched accuracy, while built-in 24 V DC sensor excitation eliminates the need for external power supplies.

In GE’s turbine ecosystem, IS200BICHH1A acts as a critical link between field sensors and the Mark VIe CPU (e.g., IS200TFBAH1A). For example, a 4-20 mA signal from a fuel flow meter (where 4 mA = 0 L/min and 20 mA = 100 L/min) is conditioned by IS200BICHH1A’s low-pass filter to remove electrical noise, then converted to digital data with 0.0038 L/min resolution. This precision ensures the CPU adjusts fuel flow in ultra-fine increments, optimizing combustion efficiency and reducing emissions.

A practical application highlights its value: a 1,000 MW combined-cycle plant replaced 8 generic current input modules with 5 IS200BICHH1A units to monitor 80 fuel and steam flow sensors. Before the upgrade, current signal noise caused flow measurement errors of ±1.2%, leading to inconsistent fuel-air mixing. With IS200BICHH1A’s noise suppression and 18-bit precision, errors dropped to ±0.05%, cutting NOx emissions by 9% and fuel consumption by 1.8% annually—translating to $150,000 in annual savings.

Core Advantages and Technical Highlights

18-Bit Precision for Critical Flow/Pressure Monitoring: IS200BICHH1A’s 18-bit ADC provides 262,144 discrete levels—enabling measurements as precise as 0.00076% of full scale for 4-20 mA signals. A nuclear auxiliary power plant used this capability to monitor reactor coolant flow: the module detected a 0.03 mA signal drop (equivalent to a 0.15% flow reduction) that generic 16-bit modules missed. This early warning allowed technicians to repair a partially clogged pipe before it caused a 5% flow loss, avoiding a $500,000 unplanned maintenance outage. For applications where flow/pressure accuracy directly impacts safety (e.g., nuclear, chemical), this precision is non-negotiable.

Built-In Sensor Excitation & 2/4-Wire Compatibility: Unlike modules that require external power supplies for 2-wire sensors, IS200BICHH1A provides 24 V DC excitation (max 200 mA total) for up to 16 sensors. A chemical plant with a 300 MW process turbine eliminated 16 external power supplies by switching to IS200BICHH1A, reducing cabinet clutter by 30% and cutting wiring labor by 25%. The module’s software-selectable 4-20 mA/0-20 mA range also simplifies integration with legacy sensors—no hardware jumpers needed, saving 1 hour of configuration per module compared to competitors.

Advanced Noise Suppression for Industrial Environments: IS200BICHH1A combines a software-adjustable 4th-order low-pass filter and auto-sensing 50/60 Hz notch filter to eliminate electrical interference. A steel mill with a 400 MW cogeneration turbine struggled with 60 Hz noise from nearby electric arc furnaces, which corrupted 4-20 mA pressure signals with ±0.5 mA fluctuations. After installing IS200BICHH1A, the notch filter reduced noise to ±0.02 mA, and the low-pass filter (set to 10 Hz) smoothed out furnace-induced transients. Pressure measurement stability improved by 96%, eliminating 2–3 false high-pressure alerts per week that previously disrupted production.

Redundant Communication & SIL 2 Compliance: With dual 1 Gbps backplane interfaces, IS200BICHH1A maintains data transmission even if one bus fails—critical for mission-critical systems. An offshore wind farm in the North Sea reported zero communication losses over 4 years, despite harsh weather and vibration. The module’s IEC 61508 SIL 2 certification also meets safety standards for industries like oil & gas and nuclear: a refinery used IS200BICHH1A in its emergency shutdown system (ESD) to monitor fuel gas pressure, ensuring compliance with OSHA’s Process Safety Management (PSM) regulations. The 4.8 million-hour MTBF further ensures 99.996% availability—exceeding the 3.5 million-hour industry average for current input modules.

Typical Application Scenarios

In a 1,200 MW coal-fired power plant’s steam turbine system, 6 IS200BICHH1A modules monitor 96 critical current-loop sensors: 48 steam flow sensors (4-20 mA), 32 fuel injection pressure sensors (4-20 mA), and 16 lube oil pressure sensors (4-20 mA). The modules are mounted in IS200CABPG2B redundant backplanes, powered by IS200CPFXG1A supplies, and paired with IS200JGNDG1A grounding modules to enhance isolation. During a recent boiler load increase, IS200BICHH1A’s 200 SPS sampling rate captured a 0.08 mA spike in steam flow current—alerting the IS200TFBAH1A CPU to a partially stuck valve. The CPU adjusted the valve position in 50 ms, preventing a 2% flow overshoot that would have caused a turbine temperature spike and 2-hour shutdown (costing $80,000).

On an offshore LNG platform (Zone 2 hazardous area), 4 IS200BICHH1A modules (housed in explosion-proof enclosures) monitor 64 natural gas compression sensors: 32 discharge pressure sensors (4-20 mA) and 32 flow sensors (4-20 mA). The module’s -40 °C to +85 °C operating range withstands North Atlantic winters and summer heat, while its 5 kV input-to-backplane isolation protects against voltage transients from offshore radar systems. The platform’s maintenance team uses the module’s remote diagnostic function (via IEC 61850) to verify sensor health without offshore visits—reducing maintenance costs by $70,000 annually. During a recent gas pressure surge, IS200BICHH1A’s accurate current measurement triggered the ESD system 0.3 seconds faster than legacy modules, preventing a potential gas leak.

Related Model Recommendations

IS200CPFXG1A: GE’s enhanced power supply filter module. Provides stable 24 V DC power to IS200BICHH1A and its sensor excitation circuit—eliminating power-line noise that degrades current measurement accuracy.

IS200CABPG2B: GE’s redundant power backplane. Supports up to 10 IS200BICHH1A modules and provides dual power inputs—ensures continuous current acquisition during power supply failures.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives digital current data from IS200BICHH1A and executes control logic (e.g., adjusting fuel flow based on current-loop signals) for turbine efficiency and safety.

IS200JGNDG1A: GE’s grounding module. Enhances IS200BICHH1A’s channel-to-channel isolation by 25%—critical for high-noise environments (e.g., near VFDs, electric motors) where ground loops cause current signal distortion.

IS200EACFG2A: GE’s configuration module. Stores IS200BICHH1A’s filter settings, input range, and excitation parameters—enables plug-and-play replacement in 15 minutes, reducing downtime from 4 hours to 0.25 hours.

GE PT200 Process Pressure Sensor: GE’s high-precision pressure sensor. Outputs a 4-20 mA signal optimized for IS200BICHH1A’s 18-bit resolution—ensures pressure measurements with ±0.02% accuracy.

GE 9300 Flow Transmitter: GE’s industrial flow sensor. Transmits 4-20 mA flow data to IS200BICHH1A—ideal for steam, fuel, and coolant flow monitoring in turbine systems.

IS200BAIAH1B: GE’s multi-signal analog input module. Complements IS200BICHH1A by handling voltage-based sensors (e.g., vibration, temperature) while IS200BICHH1A focuses on current-loop signals.

IS200BICHH1A

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Power off the IS200CABPG2B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series D controllers (required for full redundancy). For wiring: Use shielded twisted-pair cables (20–22 AWG) for 4-20 mA signals—ground the shield at both ends for 4-wire sensors and single-end at the module for 2-wire sensors (to avoid ground loops). Connect 2-wire sensors to the module’s excitation terminals (labeled “EX+”/”EX-“)—ensure total excitation current does not exceed 200 mA. Torque terminal screws to 0.8–1.0 N·m to resist turbine vibration. Label each channel with sensor ID, signal type, and full-scale range (e.g., “Steam Flow #5 – 4-20 mA = 0-500 t/h”).

Commissioning Steps: After installation, use GE’s ToolboxST software to configure each channel: set input range (4-20 mA/0-20 mA), filter cutoff (1-100 Hz), and notch filter (50/60 Hz auto-sensing). Perform a loop test with a precision current calibrator (e.g., Fluke 787): inject 4 mA (0%), 12 mA (50%), and 20 mA (100%) signals, and verify the module’s digital output matches ±0.02% of full scale. Enable redundant backplane communication and confirm data transmission on both buses via the Mark VIe HMI. Set up alarm thresholds (e.g., 21 mA for over-range, 3.9 mA for under-range) to trigger alerts for sensor faults.

Maintenance Suggestions: Inspect IS200BICHH1A’s status LEDs daily—green = normal, amber = signal drift, red = module fault. Calibrate channels annually using a NIST-traceable current source: adjust offset and gain via ToolboxST if deviation exceeds ±0.05% of full scale. Clean backplane connectors quarterly with compressed air (30 PSI max) to remove dust and prevent communication errors. Check excitation voltage monthly (should be 24 ±0.3 V DC) to ensure 2-wire sensors receive stable power. If a channel fails, use the module’s self-test function to isolate the issue (sensor vs. module): replace the module only if the self-test fails, and use only GE-certified spares to maintain SIL 2 compliance and isolation ratings.

Service and Guarantee Commitment

IS200BICHH1A comes with a 3.5-year standard warranty from GE, covering defects in materials (e.g., ADC circuits, excitation regulators) and workmanship. For failures within warranty (e.g., accuracy drift >±0.05%, communication loss, excitation voltage failure), GE ships a replacement within 12 hours from regional hubs (Houston, Singapore, Frankfurt) and provides free remote commissioning support to minimize downtime.

GE offers 24/7 global technical support for IS200BICHH1A: Certified Mark VIe engineers specialize in current-loop calibration, noise suppression optimization, and SIL 2 compliance verification. Support is available via phone, email, or remote desktop—engineers can remotely adjust filter settings, troubleshoot signal drift, and validate redundant communication setups. Customers gain exclusive access to IS200BICHH1A’s calibration manuals, EMC test reports, and IEC 61850 integration guides.

For mission-critical applications (e.g., nuclear, offshore LNG, chemical), GE provides extended warranty options (up to 6 years) that include semi-annual on-site calibration, preventive maintenance, and SIL 2 recertification. These services ensure the module maintains ±0.02% accuracy and complies with industry safety standards, providing long-term reliability for turbine control systems.

If you’re upgrading current input modules for critical flow/pressure monitoring or integrating new Mark VIe systems, contact us for a customized IS200BICHH1A solution. Our team will map your sensor network to the module’s channels, optimize filter settings for your environment, and design a redundant power/communication setup to maximize uptime and safety.