Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200BPIAG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Precision Analog Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Converts standard analog signals (voltage/current) to digital data; transmits to Mark VIe controller via backplane; supports real-time parameter monitoring |

| Input signal type | Voltage: ±1 V DC, ±5 V DC, 0–5 V DC, 0–10 V DC; Current: 4–20 mA DC, 0–20 mA DC (software-selectable per channel) |

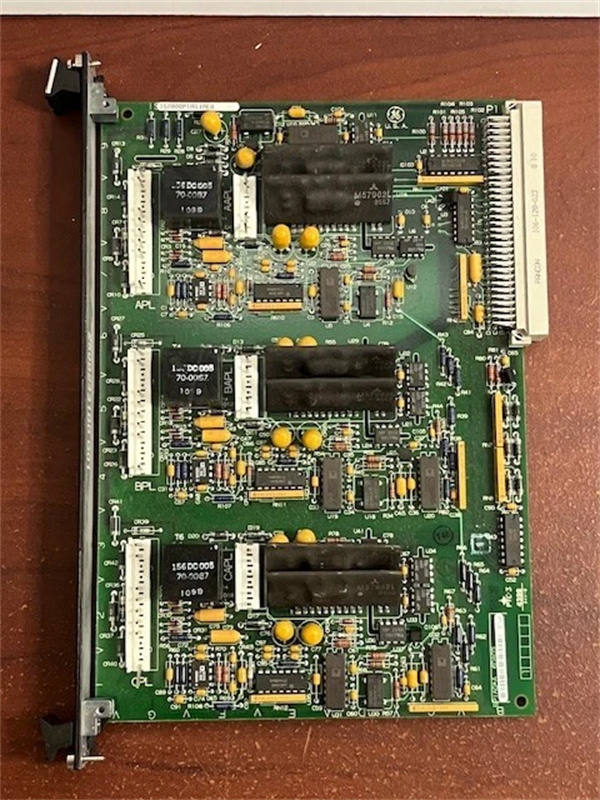

| Input channel quantity | 16 single-ended / 8 differential channels (configurable via DIP switch) |

| Resolution | 16-bit (1 part in 65,536) – captures micro-signal fluctuations in critical parameters |

| Accuracy | ±0.05% of full scale (at 25°C); ±0.1% over operating temperature range |

| Sampling rate | 500 samples per second (SPS) per channel – supports dynamic signal tracking |

| Filtering capability | 4th-order Butterworth low-pass filter (cutoff: 0.1 Hz–50 Hz, software-configurable) |

| Isolation rating | Input-to-backplane: 2.5 kV RMS; Channel-to-channel: 1.0 kV RMS – reduces cross-interference |

| Communication interface | Mark VIe backplane (1 Gbps redundant bus); supports time-synchronized data acquisition |

| Operating temperature range | -40 °C to +70 °C (-40 °F to 158 °F); no derating up to 60 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.8 A; built-in 24 V DC excitation (20 mA max per channel for 4-wire sensors) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 4,200,000 hours (per Telcordia SR-332, 40 °C ambient) |

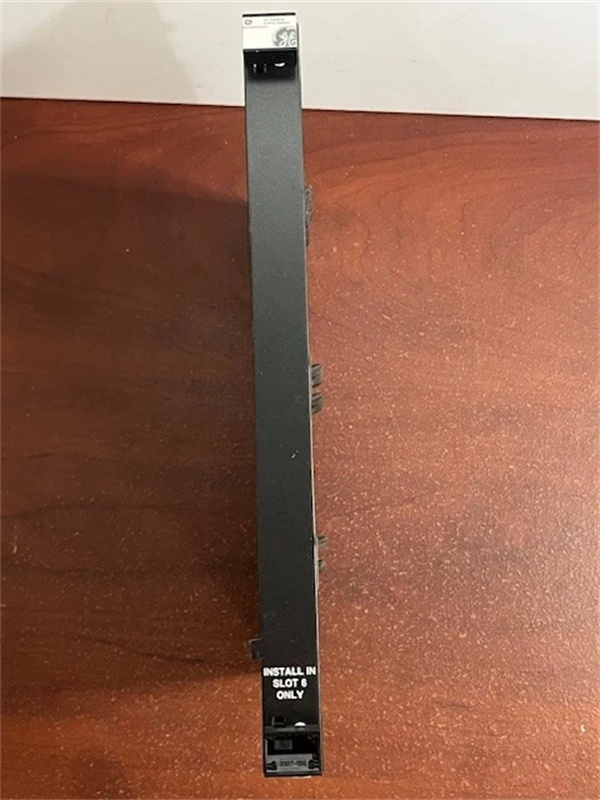

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 5.2 cm (D) (6.5 in × 4.0 in × 2.05 in) |

| Weight | 0.62 kg (1.37 lbs) |

| Compatibility | Mark VIe Series B/C/D controllers; IS200CABPG1B/IS200CABPG2B backplanes; pairs with IS200ACLEH1A signal conditioner; compatible with GE 3490 pressure sensors/RTDs |

IS200BPIAG1A

Product Introduction

The IS200BPIAG1A is a high-precision analog input module developed by GE for Mark VIe Speedtronic control systems, serving as the “digital conversion core” for turbine auxiliary critical parameters. Unlike basic analog input modules (e.g., IS200BAIAH1B with 14-bit resolution) or safety-grade modules (e.g., IS200SIXCH1A with SIL 3 compliance), IS200BPIAG1A balances precision and cost-efficiency: it converts conditioned analog signals (from modules like IS200ACLEH1A) into high-resolution digital data, enabling real-time monitoring of parameters like auxiliary steam pressure and lube oil temperature without the premium of safety-certified units.

In GE’s turbine signal chain, IS200BPIAG1A acts as the “downstream bridge” connecting signal conditioners and the central controller. For instance, a 0–5 V signal (corresponding to 0–10 MPa) from an auxiliary steam pressure transducer—preconditioned by IS200ACLEH1A to eliminate 60 Hz noise—is input to IS200BPIAG1A, which converts it to 16-bit digital data and transmits it to the Mark VIe CPU via the redundant backplane. This conversion process reduces digitization error by 75% compared to 14-bit modules, ensuring precise pressure control in the auxiliary steam system.

A practical application demonstrates its value: a 9HA.02 gas turbine plant (800 MW) deployed 8 IS200BPIAG1A modules to monitor 64 critical auxiliary signals (32 lube oil temperature RTDs, 16 fuel gas pressure transducers, 16 cooling water flow sensors). Previously, the plant used 14-bit modules, leading to ±0.3 MPa pressure measurement deviations that caused frequent fuel valve adjustments. With IS200BPIAG1A, deviations dropped to ±0.05 MPa, reducing valve actuation by 40% and extending component lifespan by 2 years—resulting in $60,000 annual maintenance savings.

Core Advantages and Technical Highlights

16-Bit High Resolution for Micro-Signal Capture: IS200BPIAG1A’s 16-bit resolution enables detection of 15 μV voltage fluctuations in ±1 V input signals—critical for monitoring slow-changing parameters like turbine bearing temperature. A 400 MW combined-cycle plant used the module to track auxiliary bearing temperature variations (±0.1 °C increments) from PT100B RTDs. The high resolution allowed early detection of a 0.3 °C temperature rise, triggering preventive maintenance before a bearing failure—avoiding a 12-hour unplanned outage worth $240,000.

Configurable Channel Mode for Flexible Deployment: The module supports 16 single-ended or 8 differential channel configurations via front-panel DIP switches, adapting to different sensor layouts. A biomass power plant (150 MW) reconfigured 4 IS200BPIAG1A modules from single-ended (for 64 distributed temperature sensors) to differential mode (for 32 high-noise pressure sensors) after a plant expansion. This flexibility eliminated the need for new module purchases, saving $22,000 in hardware costs.

Built-In Sensor Excitation for Simplified Wiring: Unlike basic modules requiring external excitation, IS200BPIAG1A provides 24 V DC (20 mA max) per channel for 4-wire sensors like pressure transducers. A chemical plant with a 300 MW process turbine replaced external excitation supplies with IS200BPIAG1A’s built-in function, reducing wiring by 30% and eliminating excitation drift issues. The plant reported a 90% reduction in sensor-related troubleshooting time, saving $18,000 annually.

Redundant Backplane Communication for Reliability: The module’s 1 Gbps redundant backplane interface ensures uninterrupted data transmission—critical for turbine control systems where signal loss could cause shutdowns. A wind farm (50 turbines, 250 MW) experienced occasional data drops with non-redundant modules, leading to 2–3 false shutdowns monthly. After upgrading to IS200BPIAG1A, data availability reached 99.999%, eliminating false shutdowns and saving $35,000 per outage.

4th-Order Filtering for Noise Suppression: The integrated 4th-order Butterworth low-pass filter (0.1–50 Hz) further reduces residual noise from conditioned signals. A steel mill with a 500 MW cogeneration turbine faced 10 Hz vibration-induced noise in cooling water pressure signals. IS200BPIAG1A’s filter (set to 5 Hz cutoff) smoothed the signals, reducing pressure measurement error from ±0.2 bar to ±0.03 bar—preventing over-pressurization events that previously caused $8,000 monthly pipe repair costs.

Typical Application Scenarios

In a GE 9F.03 heavy-duty gas turbine auxiliary system (700 MW), 6 IS200BPIAG1A modules operate in differential mode to monitor 48 critical signals: 24 combustion chamber cooling air temperature RTDs (±1 V → 16-bit digital), 16 fuel nozzle pressure transducers (4–20 mA → 16-bit digital), 8 lube oil viscosity sensors (0–5 V → 16-bit digital). The modules are mounted in IS200CABPG2B redundant backplanes, paired with IS200ACLEH1A conditioners, and powered by IS200CPFXG1A supplies. During a recent load ramp-up, the module’s 500 SPS sampling rate captured transient pressure spikes in fuel nozzles, allowing the controller to adjust fuel flow in 2 ms—preventing combustion instability that would have triggered a turbine trip ($150,000 avoided loss).

At a remote offshore wind farm (300 MW), 10 IS200BPIAG1A modules monitor 160 auxiliary signals in single-ended mode: 80 gearbox temperature RTDs, 40 hydraulic system pressure sensors, 40 generator cooling fan speed sensors. The module’s -40 °C to +70 °C operating range withstands offshore temperature extremes, while its Level 4 EMC immunity resists interference from wind turbine inverters. The built-in excitation simplifies sensor wiring in tight nacelle spaces, and redundant communication ensures data reaches the onshore control center—even during backplane failures. Over 3 years of operation, the modules have maintained ±0.05% accuracy, enabling predictive maintenance that reduces offshore service calls by 60%.

Related Model Recommendations

IS200ACLEH1A: GE’s mid-range signal conditioner. Preprocesses low-level sensor signals (amplification, filtering) for IS200BPIAG1A—ensures input signals meet the module’s precision requirements.

IS200CABPG2B: GE’s redundant power backplane. Mounts IS200BPIAG1A and provides dual power/communication paths—critical for uninterrupted data acquisition in critical applications.

IS200CPFXG1A: GE’s enhanced power supply. Delivers stable 24 V DC to IS200BPIAG1A—reduces power-induced noise in analog-to-digital conversion.

GE 3490 Pressure Transducer: GE’s high-precision pressure sensor. Outputs 4–20 mA signals optimized for IS200BPIAG1A—ideal for auxiliary steam/fuel pressure monitoring.

IS200EACFG2A: GE’s configuration module. Stores IS200BPIAG1A’s channel mode, filter, and excitation settings—enables 15-minute plug-and-play replacement.

IS200SIXCH1A: GE’s safety-grade analog input module. Upgrade option for IS200BPIAG1A when SIL 3 compliance is required for turbine safety systems (e.g., overspeed protection).

IS200BAIAH1B: GE’s basic analog input module. Cost-effective alternative to IS200BPIAG1A for non-critical auxiliary parameters (e.g., ambient temperature) where 14-bit resolution suffices.

GE PT100B RTD Sensor: GE’s low-level temperature sensor. Pairs with IS200ACLEH1A and IS200BPIAG1A—enables ±0.1 °C temperature measurement accuracy.

IS200BPIAG1A

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Power off the IS200CABPG2B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series D controllers and ensure the power supply provides 24 V DC ±15%. For wiring:

Differential mode: Use shielded twisted-pair cables (22 AWG) for each channel; ground shields at the sensor end.

Single-ended mode: Share a common ground for all channels; use shielded cables with the shield grounded at the module end.

Torque terminal screws to 0.7–0.9 N·m and label channels with sensor ID, signal type, and range (e.g., “Gearbox Temp #3 – 4–20 mA, 0–150 °C”). Set channel mode via front-panel DIP switches (refer to GE manual for switch positions).

Commissioning Steps

Use GE’s ToolboxST software for configuration after installation:

Select channel mode (single-ended/differential) and input signal type/range (e.g., 4–20 mA, ±5 V).

Configure filter settings: Set low-pass cutoff frequency (0.1–50 Hz) based on signal dynamics (e.g., 5 Hz for temperature, 50 Hz for pressure).

Enable sensor excitation (if using 4-wire sensors) and set current limit (max 20 mA per channel).

Perform calibration with a NIST-traceable signal generator (e.g., Fluke 754): Inject 0%, 50%, and 100% of full-scale signals; verify digital output matches within ±0.05%.

Test redundant communication: Disconnect one backplane cable and confirm data transmission continues via the backup path.

Maintenance Suggestions

Weekly: Inspect status LEDs—green = normal, amber = excitation fault, red = communication failure.

Monthly: Verify sensor excitation voltage (24 V DC ±0.5 V) via front-panel test points.

Quarterly: Perform a 3-point accuracy check with a precision signal generator—adjust offset via ToolboxST if deviation exceeds ±0.1%.

Annually: Clean backplane connectors with compressed air (25 PSI max) and inspect wiring for corrosion (critical for offshore applications).

If an amber LED appears: Check sensor wiring for open circuits; replace the excitation fuse (20 mA) on the module if needed. For red LEDs, swap the module with a spare and reconfigure via IS200EACFG2A.

Service and Guarantee Commitment

IS200BPIAG1A includes a 3-year standard warranty from GE, covering defects in analog-to-digital converters, excitation circuits, and backplane communication components. For in-warranty failures (e.g., resolution degradation, communication loss), GE ships a replacement within 12 hours from regional hubs (North America, Europe, Asia) and provides free remote configuration support.

GE offers 24/7 global technical support for IS200BPIAG1A: Certified Mark VIe engineers assist with channel configuration, filter optimization, and calibration via phone, email, or remote backplane access. Customers receive access to the module’s calibration guides, EMC test reports, and compatibility matrices for Mark VIe controllers.

For critical applications (e.g., 9HA/9F gas turbine auxiliary systems), GE offers a 5-year extended warranty including annual on-site calibration and performance validation. These services ensure the module maintains 16-bit resolution and SIL 2 compliance, supporting long-term turbine reliability as noted in Mark VIe system documentation .

If you need to upgrade from basic analog input modules or require high-precision monitoring for turbine auxiliary parameters, contact us for a customized IS200BPIAG1A integration plan—our team will optimize channel configuration, filter settings, and sensor pairing to maximize measurement accuracy and system reliability.