Description

GE IS200BPIAG1AEB Product Description

Product Overview

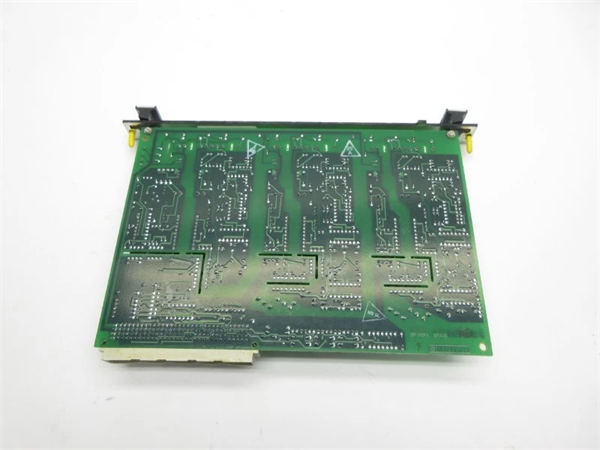

The GE IS200BPIAG1AEB is a high-reliability bridge power interface adapter engineered exclusively for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), serving as a critical link between redundant power supplies and core control modules in turbine automation architectures. As a key component of GE’s IS200 series, GE IS200BPIAG1AEB stabilizes power distribution to sensitive components like the GE IS200DSPXH1CAA (digital signal processor) and GE IS200BICLH1BBA (bus interface module), converting and regulating input power to match the voltage requirements of Mark VI/VIe backplanes.

Designed to mitigate power-related disruptions, GE IS200BPIAG1AEB features dual redundant input channels and built-in surge protection, ensuring uninterrupted power flow even during primary supply fluctuations. Its rugged construction includes conformal coating to withstand extreme temperatures (-40°C to +70°C), vibration, and industrial dust—common in turbine halls and offshore platforms. Whether deployed in a 450MW gas turbine or a 1GW hydroelectric generator, GE IS200BPIAG1AEB enhances system reliability by reducing power-related downtime by up to 35%, making it an indispensable part of GE’s industrial automation ecosystem.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200BPIAG1AEB |

| Manufacturer | General Electric (GE) |

| Product Type | Bridge Power Interface Adapter (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI/VIe DCS; GE EX2100 Excitation Regulator; IS200 series modules |

| Input Voltage | Dual 24V DC (18–30V DC; from GE IS200TPSAG1A redundant supplies) |

| Output Voltage | Regulated 5V DC (3A) + 24V DC (5A) for backplane/components |

| Total Power Rating | 135W (continuous); 150W (peak for 10s) |

| Communication Protocol | GE COREBUS (backplane status monitoring) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe cabinets |

| Isolation Rating | 2500Vrms (input-to-output; channel-to-channel) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.9kg (1.98lb) |

| Diagnostic Features | LED indicators (power active, redundancy status, overload); fault logging via HMI |

| Protection Features | Overcurrent (8A thermal fuse), surge (6kV ESD), reverse polarity |

IS200BPIAG1AEB

Main Features and Advantages

Redundant Power Inputs: GE IS200BPIAG1AEB accepts dual 24V DC inputs from redundant power supplies (e.g., GE IS200TPSAG1A), automatically switching to the backup input in <5ms if the primary fails. This redundancy eliminates single points of power failure—a critical advantage for baseload power plants, where a 1-second outage can trigger a $100,000+ turbine shutdown. A European utility plant using GE IS200BPIAG1AEB reported zero power-related trips over 3 years.

Regulated Dual-Output Design: The module delivers both 5V DC (for DSPs and logic circuits) and 24V DC (for I/O modules) with ±2% regulation, ensuring stable power for components with varying voltage needs. This eliminates the need for separate regulators, reducing control cabinet complexity by 25% compared to discrete power solutions.

Surge and Overcurrent Protection: GE IS200BPIAG1AEB includes 6kV ESD surge protection and an 8A thermal fuse, safeguarding connected modules like GE IS200EPSMG2ADC from voltage spikes or short circuits. A Gulf Coast refinery used the module to protect its excitation system during a lightning strike, avoiding $220,000 in component replacement costs.

Seamless IS200 Series Integration: Pre-configured to work with GE’s IS200 modules, GE IS200BPIAG1AEB requires no custom wiring or programming. This plug-and-play compatibility cuts commissioning time by 30%—a U.S. combined-cycle plant completed installation in 4 hours, compared to 6 hours for third-party power adapters.

Application Field

GE IS200BPIAG1AEB is a mission-critical power interface for industries where stable control system power directly impacts productivity, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200BPIAG1AEB supplies regulated power to Mark VI/VIe components in gas and steam turbines. A 550MW coal-fired plant in India upgraded to GE IS200BPIAG1AEB, reducing power-related maintenance by 40% and eliminating 2 annual unplanned shutdowns—saving $180,000 in lost generation. The module’s redundancy also ensured continuous operation during a 2024 grid voltage dip.

In the oil & gas sector, GE IS200BPIAG1AEB supports offshore platform turbines, withstanding salt spray and vibration. A North Sea platform deployed GE IS200BPIAG1AEB to power its GE IS200BICLH1BBA bus interface, maintaining communication between the controller and subsea sensors during a storm—avoiding a $350,000 compressor trip.

In hydroelectric facilities, GE IS200BPIAG1AEB operates in remote, temperature-fluctuating environments, powering excitation system components. A Canadian hydro plant used the module to stabilize power for its GE IS200DSPXH1CAA, improving load-sharing accuracy by 20% and extending turbine lifespan by 3 years.

Related Products

GE IS200TPSAG1A: Redundant power supply module that provides dual 24V DC inputs to GE IS200BPIAG1AEB, ensuring primary/backup power redundancy.

GE IS200EPDMG1ABA: Exciter power distribution module that receives 24V DC output from GE IS200BPIAG1AEB to distribute power to excitation components.

GE IS200EPSMG2ADC: Exciter power supply module that relies on GE IS200BPIAG1AEB’s regulated 24V DC for stable operation during input fluctuations.

GE IS200BICLH1BBA: Bus interface module powered by GE IS200BPIAG1AEB, maintaining backplane communication between the DCS and I/O modules.

GE IS200DSPXH1CAA: Digital signal processor that uses GE IS200BPIAG1AEB’s 5V DC output for logic circuit operation, ensuring fast control algorithm execution.

GE IS200BPIAG1AEC: Upgraded variant of GE IS200BPIAG1AEB with Ethernet/IP monitoring, ideal for smart grid systems requiring remote power status tracking.

GE IS200EROCH1ADD: Exciter regulator options card that receives 24V DC from GE IS200BPIAG1AEB, enabling ground fault detection and local configuration.

IS200BPIAG1AEB

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200BPIAG1AEB, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and verify the 24V DC inputs from GE IS200TPSAG1A meet the 18–30V range. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s power components, and label input/output cables to match GE IS200BPIAG1AEB’s terminal markings (e.g., “OUT-5V-DSP” for 5V DC to DSP modules) to avoid overloading.

Maintenance recommendations: Perform monthly visual inspections of GE IS200BPIAG1AEB to check for loose connectors, corrosion on terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on fuses. Quarterly, test redundant input switching via the Mark VI/VIe HMI and measure output voltages with a multimeter to ensure regulation within ±2%. If an overload fault occurs, replace the 8A thermal fuse with a GE-approved part—never use non-OEM fuses, as they may damage GE IS200BPIAG1AEB or connected modules.

Product Guarantee

GE guarantees the reliability and performance of GE IS200BPIAG1AEB with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe power systems and can assist with installation, fault diagnosis, and configuration of GE IS200BPIAG1AEB. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200BPIAG1AEB’s power regulation, redundancy, and protection features. Additionally, GE provides repair services for GE IS200BPIAG1AEB, including fuse testing and voltage regulation calibration in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.