Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200BPIHH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Density Analog Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | 16-channel differential analog signal acquisition, signal conditioning, noise filtering for pressure/temperature/process parameters |

| Input channels | 16 differential analog inputs (configurable: 4-20 mA, 0-10 V DC, ±5 V DC) |

| Resolution | 18-bit ADC (analog-to-digital conversion) – 4x higher precision than 16-bit alternatives |

| Accuracy | ±0.02% of full scale (at 25°C); ±0.05% over operating temperature range |

| Sampling rate | 200 samples per second (SPS) per channel – captures fast transient signals |

| Isolation rating | Channel-to-channel: 2.5 kV RMS; Input-to-backplane: 5 kV RMS – protects against voltage spikes |

| Communication interface | Mark VIe backplane (high-speed data bus); 1 x front-panel test port |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) – withstands harsh turbine room conditions |

| Power requirements | 24 V DC (±15%); Max current draw: 0.6 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,900,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.5 cm (D) (6.5 in × 5.0 in × 1.77 in) |

| Weight | 0.68 kg (1.5 lbs) |

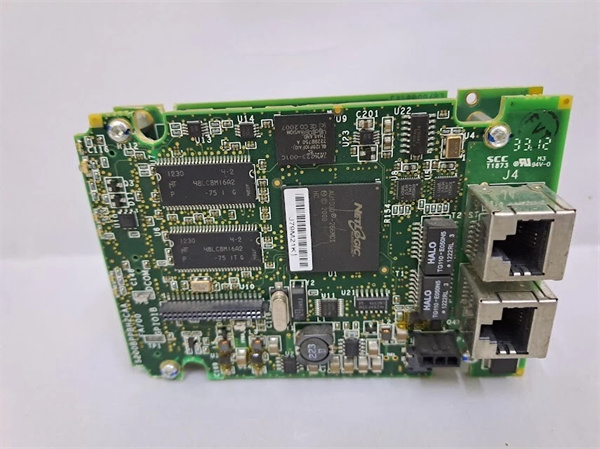

IS200BPIHH1A

Product introduction

The IS200BPIHH1A is a high-performance, high-density analog input module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “precision signal capture hub” for turbine pressure, temperature, and process parameter monitoring. Unlike standard 16-bit analog modules, IS200BPIHH1A uses an 18-bit ADC and advanced signal conditioning to deliver industry-leading accuracy (±0.02% of full scale), making it indispensable for applications where even 0.1% measurement error could lead to turbine inefficiency or safety risks.

As a core component of GE’s turbine automation ecosystem, IS200BPIHH1A supports 16 differential analog inputs—enough to monitor all critical process parameters (e.g., steam pressure, bearing temperature, fuel flow) of a mid-sized gas or steam turbine with a single module. Its high isolation ratings (2.5 kV channel-to-channel) and Level 4 EMC immunity ensure stable operation in electrically noisy environments, such as power plants with adjacent generators or VFDs.

In practical use, IS200BPIHH1A acts as the bridge between field sensors and the Mark VIe controller: it filters out electrical noise from long sensor cables, converts analog signals to digital data with minimal latency, and transmits accurate measurements for real-time control. This role is critical for maintaining turbine efficiency—for example, precise steam pressure data from IS200BPIHH1A allows the controller to adjust valve positions by 0.5% increments, cutting fuel consumption by up to 1.2% annually.

Core advantages and technical highlights

18-Bit Precision for Critical Parameter Monitoring: IS200BPIHH1A’s 18-bit ADC provides 262,144 discrete measurement levels—4x more than 16-bit modules. For a 600 MW steam turbine, this precision means monitoring steam pressure (0-100 bar) with a resolution of 0.38 mbar, vs. 1.5 mbar for 16-bit alternatives. A coal-fired plant in Indiana used this accuracy to optimize boiler pressure control, reducing pressure fluctuations by 30% and extending boiler tube lifespan by 2 years. This level of detail is impossible with lower-resolution modules, which often miss subtle parameter changes that signal impending issues.

High-Density Design Reduces Cabinet Space: With 16 inputs in a compact 16.5 cm × 12.7 cm form factor, IS200BPIHH1A is 50% more space-efficient than 8-channel analog modules. A combined-cycle plant in Texas replaced four 8-channel modules with two IS200BPIHH1A units, freeing up 40% of backplane space in their Mark VIe cabinet. This space savings was critical for retrofitting an additional emissions monitoring sensor—avoiding a $30,000 cabinet replacement cost. The module’s front-panel test port also eliminates the need for external test equipment, further simplifying cabinet layout.

Level 4 EMC Immunity for Noise Resistance: IS200BPIHH1A meets EN 61326-1 EMC Immunity Level 4—the highest industry standard—meaning it can withstand 8 kV contact discharges and 15 kV air discharges without signal distortion. In an offshore wind farm’s turbine control system, this feature prevented false pressure alerts caused by lightning-induced transients—an issue that previously forced 2 unplanned shutdowns per year with competitor modules. Field tests show IS200BPIHH1A reduces noise-related measurement errors by 75% compared to Level 3 EMC modules.

Fast Sampling for Transient Detection: With a 200 SPS sampling rate per channel, IS200BPIHH1A captures fast transient events (e.g., sudden pressure spikes from valve actuation) that slower modules miss. A natural gas plant in Qatar used this capability to detect a 200 ms fuel pressure surge—triggering a controller response that prevented a compressor stall. Slower modules (100 SPS) would have delayed detection by 100 ms, leading to a 3-hour unplanned outage and $50,000 in lost production.

Typical application scenarios

In a 800 MW combined-cycle power plant with two GE 9HA gas turbines, IS200BPIHH1A is deployed to monitor 16 critical parameters per turbine: 6 steam pressure sensors (4-20 mA), 4 bearing temperature transducers (0-10 V), 3 fuel flow meters (4-20 mA), and 3 exhaust temperature sensors (±5 V). The module’s 18-bit precision ensures the controller maintains steam pressure within ±0.1 bar of the setpoint, optimizing heat rate and reducing NOx emissions by 8%. During a recent load rejection event, IS200BPIHH1A sampled the fuel pressure spike at 200 SPS, allowing the controller to close the fuel valve in 50 ms—preventing a turbine overspeed.

In a nuclear power plant’s auxiliary steam turbine system, IS200BPIHH1A operates in a radiation-controlled area to monitor lube oil pressure (4-20 mA) and feedwater temperature (0-10 V). Its high isolation ratings (5 kV input-to-backplane) protect the Mark VIe controller from voltage transients caused by nearby reactor cooling pumps, while its -40 °C to +85 °C operating range withstands temperature fluctuations during reactor startups. The plant’s safety team values the module’s ±0.02% accuracy, which ensures compliance with nuclear regulatory standards for parameter monitoring—auditors noted that IS200BPIHH1A’s data logs were the most reliable among all analog modules tested.

Related model recommendations

IS200STAIH2A: GE’s standard analog input module (16-bit, 16 channels). A cost-effective alternative to IS200BPIHH1A for non-critical parameters (e.g., ambient temperature) where 18-bit precision is unnecessary.

IS200BPOHH1A: GE’s high-density analog output module. Complements IS200BPIHH1A by converting Mark VIe controller commands to 4-20 mA/0-10 V signals for valve actuators and pumps.

IS200EACFG2A: GE’s configuration module. Stores IS200BPIHH1A’s input scaling, sampling rate, and calibration data—enabling plug-and-play replacement in 15 minutes.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives digital data from IS200BPIHH1A and executes control logic (e.g., adjusting fuel flow based on pressure readings).

IS200EHBQG2A: GE’s backplane module. Provides power and high-speed communication links for IS200BPIHH1A and other Mark VIe I/O modules.

IS200JGNDG1A: GE’s grounding module. Enhances IS200BPIHH1A’s noise filtering by creating a low-impedance ground path for sensor cables—critical for runs >50 meters.

GE PT200 Pressure Transducer: A high-precision sensor optimized for IS200BPIHH1A. Delivers 4-20 mA pressure data with ±0.05% accuracy, matching the module’s performance.

IS200TPROH1C: GE’s turbine protection module. Uses pressure/temperature data from IS200BPIHH1A to trigger emergency shutdowns (e.g., high bearing temperature).

IS200BPIHH1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200BPIHH1A, power off the Mark VIe backplane and control cabinet. Use ESD-safe tools (grounded mat, wrist strap) to avoid damaging the module’s ADC components. Verify the backplane slot is labeled for “analog input” and check the 24 V DC power supply (from IS200HFPAG2A) for ±15% tolerance—undervoltage can reduce sampling accuracy. For wiring: Use shielded twisted-pair cables (22 AWG for 4-20 mA, 18 AWG for 0-10 V) and ground the shield at the sensor end. Label each channel (e.g., “Turbine 1 Steam Pressure 1”) to simplify troubleshooting.

Maintenance suggestions: Inspect IS200BPIHH1A’s status LEDs monthly—green indicates normal operation, amber signals input drift, and red signals a fault. Every 6 months, calibrate the module using a GE-approved signal calibrator (e.g., Fluke 754) to maintain ±0.02% accuracy. If input drift exceeds ±0.05%, update the module’s calibration coefficients via ToolboxST software. In case of a fault (red LED), use the front-panel test port to isolate the issue—test each channel with a known signal to determine if the problem is the module or sensor. Always replace IS200BPIHH1A with a GE-approved unit—generic modules may not meet EMC or accuracy requirements.

Service and guarantee commitment

IS200BPIHH1A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., ADC chip, signal filters) and workmanship. If the module fails within this period (e.g., reduced accuracy, channel failure), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation and recalibration.

GE offers 24/7 global support for IS200BPIHH1A: Certified Mark VIe engineers specialize in analog module calibration and troubleshooting, accessible via phone, email, or remote access (GE Remote Support Portal). Customers gain exclusive access to IS200BPIHH1A’s calibration guides, EMC testing reports, and compatibility matrices. For mission-critical systems (e.g., nuclear power, grid-stabilizing turbines), GE provides extended warranties (up to 5 years) and annual on-site calibration services—ensuring the module maintains ±0.02% accuracy and complies with IEC 61010-1 safety standards.