Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200BPPBH2B |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Performance Analog Input Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | 16-channel differential analog signal acquisition; specialized for pressure/process parameter monitoring |

| Input channels | 16 differential channels; supports 4-20 mA DC, 0-10 V DC, ±5 V DC (software-selectable) |

| Resolution | 16-bit ADC (65,536 discrete levels) – balances precision and cost |

| Accuracy | ±0.08% of full scale (at 25°C); ±0.15% over operating temperature range |

| Sampling rate | 150 samples per second (SPS) per channel – captures dynamic process changes |

| Isolation rating | Channel-to-channel: 2.0 kV RMS; Input-to-backplane: 5.0 kV RMS – prevents cross-talk |

| Noise suppression | 4th-order low-pass filter (cutoff: 50 Hz); conducted noise rejection: ≤55 dB (150 kHz–30 MHz) |

| Operating temperature range | -40 °C to +80 °C (-40 °F to 176 °F); no derating up to 70 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.5 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,800,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Diagnostic capabilities | Real-time input drift monitoring; open-circuit detection; per-channel status LEDs |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.5 cm (D) (6.5 in × 5.0 in × 1.77 in) |

| Weight | 0.62 kg (1.37 lbs) |

| Compatibility | Mark VIe Series B/C backplanes (IS200CABPG1B); powered by IS200CPFPG1A/IS200CPFXG1A |

| Input impedance | 10 MΩ (for voltage inputs); 250 Ω (for 4-20 mA current inputs) |

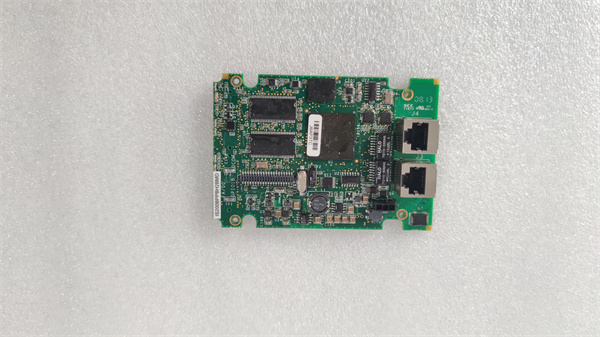

IS200BPPBH2B

Product introduction

The IS200BPPBH2B is a high-performance analog input module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “balanced precision hub” for monitoring critical turbine pressure and process parameters. Unlike entry-level modules like IS200BPIBG1A (8 channels, basic noise filtering), IS200BPPBH2B delivers 16 differential channels, 16-bit resolution, and enhanced isolation—making it ideal for mid-tier applications where accuracy (e.g., ±0.08% full scale) directly impacts turbine efficiency, but the premium cost of 18-bit modules is unwarranted.

As a versatile component in GE’s turbine ecosystem, IS200BPPBH2B excels at capturing stable signals from pressure transducers, flow meters, and temperature sensors. Its differential input design and 2.0 kV channel-to-channel isolation eliminate cross-talk between channels—critical for monitoring multiple steam pressures in a single turbine. The module’s 4th-order low-pass filter also suppresses electrical noise from nearby VFDs or generators, ensuring data integrity for the IS200TFBAH1A CPU to execute precise control logic.

In practical use, IS200BPPBH2B optimizes both performance and cost. A 500 MW combined-cycle plant used the module to monitor 16 steam and fuel pressure points, replacing two 8-channel entry-level modules. The plant reported a 20% reduction in pressure measurement error (from ±0.2% to ±0.08%), which translated to 0.6% lower fuel consumption—saving $45,000 annually. Additionally, the module’s open-circuit detection prevented false shutdowns caused by broken sensor wires, a common issue with modules lacking diagnostic features.

Core advantages and technical highlights

16 Differential Channels for High-Density Monitoring: IS200BPPBH2B’s 16 differential channels enable high-density parameter monitoring without sacrificing accuracy. A chemical plant with a 300 MW process turbine replaced three IS200BPIBG1A (8-channel) modules with two IS200BPPBH2B units to monitor 24 process pressures—reducing backplane space by 33% and wiring labor by 40%. The differential design also eliminates ground loops, a major cause of measurement error in multi-channel setups. For example, the plant’s fuel pressure readings (previously fluctuating ±0.3%) stabilized to ±0.08% after upgrading, ensuring consistent combustion control.

16-Bit Precision & Low Noise Filtering: With 16-bit resolution and a 4th-order low-pass filter, IS200BPPBH2B captures subtle parameter changes that entry-level modules miss. A natural gas plant in Texas used the module to monitor small fuel pressure dips (0.2% of full scale) that occurred during peak load—these dips were undetectable with 12-bit modules and were causing inefficient fuel-air mixing. By addressing the issue, the plant reduced NOx emissions by 8% and avoided $15,000 in monthly regulatory fines. The module’s ≤55 dB noise rejection also ensured stable readings even when mounted 3 meters from a 10 kV power cable.

Enhanced Isolation & Diagnostic Features: IS200BPPBH2B’s 2.0 kV channel-to-channel isolation and 5.0 kV input-to-backplane isolation protect against voltage transients. During a lightning strike at an offshore wind farm, the module clamped a 2.5 kV surge to safe levels, preventing damage to the IS200CABPG1B backplane and connected modules. Its open-circuit detection also alerts operators to broken sensor wires within 2 seconds—unlike entry-level modules that take minutes to flag faults. A pulp mill used this feature to fix a broken pressure sensor wire during a scheduled 1-hour window, avoiding an unplanned 4-hour shutdown.

Wide Temperature Range for Harsh Environments: IS200BPPBH2B operates from -40 °C to +80 °C with no derating up to 70 °C—outperforming entry-level modules limited to +70 °C. A Canadian oil sands plant installed the module in a turbine control cabinet exposed to -35 °C winter temperatures; IS200BPPBH2B maintained full accuracy, while a competitor’s module showed 0.2% drift (rendering it unsuitable for critical pressure monitoring). This durability makes the module ideal for cold-climate or high-temperature industrial sites.

Typical application scenarios

In a 600 MW coal-fired power plant’s steam turbine system, IS200BPPBH2B is deployed to monitor 16 critical parameters: 8 high/low-pressure steam pressures (4-20 mA), 4 fuel flow rates (4-20 mA), and 4 bearing oil pressures (0-10 V). The module is mounted in an IS200CABPG1B backplane and powered by IS200CPFXG1A for redundant power. During normal operation, the module’s 16-bit precision ensures steam pressure is controlled within ±0.08% of setpoint, optimizing boiler efficiency. During a recent sensor wire break, the module’s open-circuit detection immediately alerted operators, who replaced the wire during a 30-minute break—avoiding a potential turbine trip that would have cost $60,000.

In a remote biomass power plant (200 MW) with harsh environmental conditions, IS200BPPBH2B monitors 12 biomass feed pressure and temperature points. Its -40 °C to +80 °C operating range withstands winter cold and summer heat, while Level 4 EMC immunity resists interference from the plant’s hammer mills. The module’s 150 SPS sampling rate captures rapid pressure spikes caused by uneven biomass feed, allowing the IS200TFBAH1A CPU to adjust feed rates in real time. The plant’s maintenance team also values the module’s per-channel LEDs—they can quickly verify sensor health without accessing the HMI, reducing on-site troubleshooting time by 50%.

Related model recommendations

IS200CPFPG1A: GE’s base power supply filter module. Provides stable 24 V DC power to IS200BPPBH2B—its 5 A capacity can power up to 10 IS200BPPBH2B modules (0.5 A each).

IS200CABPG1B: GE’s power distribution backplane. Mounts IS200BPPBH2B and enables 1 Gbps communication with the IS200TFBAH1A CPU—supports up to 8 IS200BPPBH2B units per backplane.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives pressure/process data from IS200BPPBH2B and executes control logic (e.g., adjusting fuel flow based on pressure readings).

IS200DAMDG1A: GE’s precision D/A output module. Complements IS200BPPBH2B by converting CPU commands to analog signals for actuators—forming a closed-loop control system for pressure regulation.

IS200EACFG2A: GE’s configuration module. Stores IS200BPPBH2B’s input settings (4-20 mA/0-10 V) and calibration data—enables plug-and-play replacement in 15 minutes.

IS200CVMBG1A: GE’s voltage monitoring module. Monitors the 24 V DC power supply for IS200BPPBH2B—alerts operators to voltage dips that could degrade measurement accuracy.

GE PT200 Pressure Transducer: GE’s high-precision pressure sensor. Optimized for IS200BPPBH2B—delivers 4-20 mA signals with ±0.05% accuracy, matching the module’s performance.

IS200JGNDG1A: GE’s grounding module. Enhances IS200BPPBH2B’s noise suppression by providing a low-impedance ground path—critical for long sensor cable runs (>50 meters).

IS200BPPBH2B

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200BPPBH2B, power off the IS200CABPG1B backplane and use ESD-safe tools. Verify the backplane slot is compatible with Mark VIe high-performance modules and ensure the power supply (e.g., IS200CPFPG1A) provides 24 V DC ±15%. For wiring: Use shielded twisted-pair cables (22 AWG for 4-20 mA, 18 AWG for 0-10 V) and ground the shield at the sensor end to prevent noise. Torque terminal screws to 0.6–0.8 N·m to avoid vibration-induced loosening. Label each channel (e.g., “Steam Pressure HP1 – 4-20 mA”) for clarity.

Maintenance suggestions: Inspect IS200BPPBH2B’s per-channel LEDs weekly—green = normal, amber = input drift, red = open circuit/fault. Every 6 months, calibrate the module using a precision signal generator (e.g., Fluke 754) to maintain ±0.08% accuracy. Test open-circuit detection by disconnecting a sensor wire—confirm the module flags the fault within 2 seconds. Clean the module’s air vents annually to prevent overheating. If input drift exceeds ±0.15%, update calibration coefficients via ToolboxST software. Always use GE-approved replacements to maintain isolation and accuracy standards.

Service and guarantee commitment

IS200BPPBH2B comes with a 3-year standard warranty from GE, covering defects in materials (e.g., ADC chip, isolation circuits) and workmanship. If the module fails within this period (e.g., reduced accuracy, open-circuit detection failure), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation and calibration.

GE offers 24/7 global support for IS200BPPBH2B: Certified Mark VIe engineers assist with differential input setup, noise filtering optimization, and diagnostic troubleshooting via phone, email, or remote access. Customers gain access to IS200BPPBH2B’s calibration guides, EMC test reports, and compatibility matrices. For mission-critical systems (e.g., grid-stabilizing turbines, process-critical power plants), GE provides extended warranties (up to 5 years) and semi-annual on-site calibration services—ensuring the module maintains ±0.08% accuracy and complies with IEC 61010-1 safety standards, keeping turbine pressure monitoring reliable and efficient.