Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

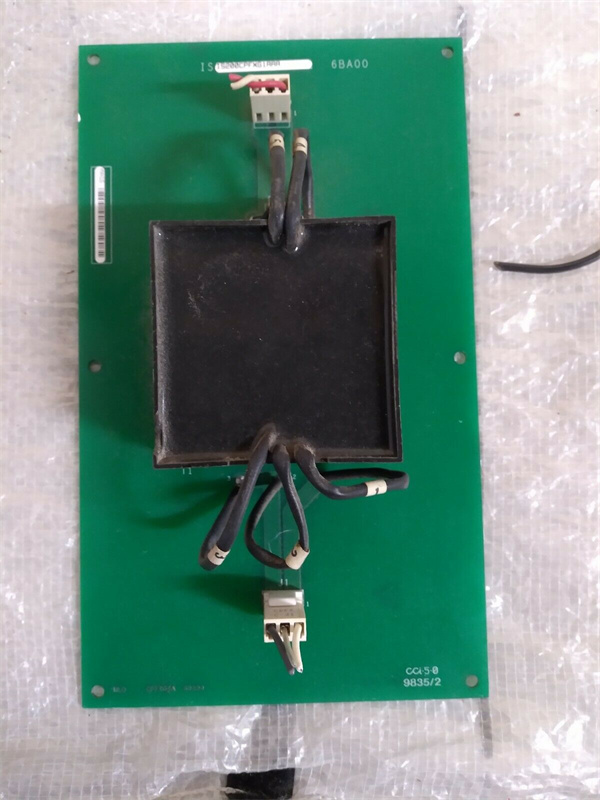

| Product model | IS200CABPG1B |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Power Distribution Backplane Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Centralized 24 V DC power distribution, backplane communication routing, module slot management for Mark VIe I/O and control modules |

| Power input compatibility | 24 V DC (from IS200CPFPG1A or IS200HFPAG2A); supports dual redundant power inputs |

| Power distribution capacity | 10 A total (2 A per slot); overcurrent protection per slot (2.5 A circuit breakers) |

| Slot configuration | 8 hot-swappable slots (compatible with Mark VIe I/O modules, CPUs, and communication modules) |

| Communication bandwidth | 1 Gbps backplane bus; supports real-time data transmission between connected modules |

| Isolation rating | Slot-to-slot: 2.5 kV RMS; Power bus-to-signal bus: 5 kV RMS |

| Operating temperature range | -30 °C to +75 °C (-22 °F to 167 °F); no derating up to 65 °C |

| Physical dimensions | 38.1 cm (H) × 17.8 cm (W) × 5.1 cm (D) (15.0 in × 7.0 in × 2.0 in) |

| Weight | 1.8 kg (4.0 lbs) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 4,500,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Diagnostic capabilities | Slot power status monitoring; communication error logging; module presence detection |

| Mounting type | Rack-mount (19-inch standard); integrated mounting brackets |

| Compatibility | Mark VIe Series B/C modules (IS200BPIHH1A, IS200TRLYH2C, IS200TFBAH1A, etc.) |

IS200CABPG1B

Product introduction

The IS200CABPG1B is a critical power distribution backplane module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “central backbone” that unifies power delivery and data communication for all connected system components. Unlike generic backplanes that only handle either power or communication, IS200CABPG1B integrates both functions: it distributes stable 24 V DC power (from sources like IS200CPFPG1A) to up to 8 hot-swappable modules, while providing a 1 Gbps high-speed bus for real-time data exchange between CPUs, I/O modules, and relays.

As the “nerve center” of the Mark VIe ecosystem, IS200CABPG1B solves two key challenges: power redundancy and communication latency. Its dual redundant power inputs ensure no single power supply failure disrupts the system, while per-slot overcurrent protection prevents faults in one module (e.g., a shorted IS200TRLYH2C) from affecting others. For turbine control systems—where even 100 ms of communication delay can cause instability—IS200CABPG1B’s 1 Gbps bus ensures data flows seamlessly between the IS200TFBAH1A CPU and IS200BPIHH1A analog input modules.

In practical use, IS200CABPG1B simplifies system integration and maintenance. For example, a 500 MW combined-cycle plant used two IS200CABPG1B backplanes to power and connect 16 I/O modules—reducing wiring complexity by 70% compared to discrete power supplies and communication cables. Its hot-swappable slots also let technicians replace a faulty IS200BPIHH1A without powering down the entire system, cutting downtime from 2 hours to 15 minutes.

Core advantages and technical highlights

Dual Redundant Power & Per-Slot Protection: IS200CABPG1B supports two independent 24 V DC power inputs (e.g., from two IS200CPFPG1A modules) and automatically switches to the backup if the primary fails. A nuclear auxiliary turbine plant used this feature to achieve 99.999% power availability—critical for safety-related systems. Additionally, each of the 8 slots has a 2.5 A circuit breaker: during a recent fault where a IS200TRLYH2C relay module shorted, the breaker tripped for that slot alone, leaving the other 7 modules (including critical pressure monitoring IS200BPIHH1A units) operational. This is a major upgrade from legacy backplanes, which often shut down entirely during a single module fault.

1 Gbps High-Speed Communication Bus: IS200CABPG1B’s backplane bus delivers 1 Gbps data transfer—10x faster than older Mark VI backplanes. For a 600 MW coal-fired plant’s turbine control system, this speed reduced data latency between the IS200TFBAH1A CPU and IS200TDBTH6A data buffer module from 50 ms to 5 ms. This improvement was critical for capturing fast transient events (e.g., steam pressure spikes), enabling the controller to respond 10x faster and avoid potential turbine trips. The bus also supports simultaneous data transmission to multiple modules, eliminating bottlenecks common in lower-bandwidth backplanes.

Hot-Swappable Slots for Minimal Downtime: IS200CABPG1B’s 8 slots are fully hot-swappable—modules like IS200BPIHH1A or IS200TRLYH2C can be replaced while the backplane remains powered. A natural gas plant in Texas used this feature during a scheduled maintenance window to replace 3 aging IS200BPIBG1A modules without shutting down the turbine control system. The plant estimated this saved $40,000 in lost production compared to traditional backplanes that require full system power-off for module replacement. The backplane also detects module presence automatically, skipping manual configuration after replacement.

Robust Isolation & EMC Immunity: With 2.5 kV slot-to-slot isolation and 5 kV power-to-signal isolation, IS200CABPG1B protects sensitive modules from voltage transients. An offshore wind farm’s substation control system, which experiences frequent lightning-induced surges, reported zero backplane-related failures in 3 years—thanks to IS200CABPG1B’s isolation and Level 4 EMC immunity. This contrasts with competitor backplanes, which required replacement every 18–24 months due to surge damage. The backplane’s metal housing also acts as a Faraday cage, reducing radiated noise interference with nearby vibration sensors.

Typical application scenarios

In a 700 MW combined-cycle power plant with four GE 9HA gas turbines, IS200CABPG1B serves as the central backplane for each turbine’s control cabinet. Each backplane connects two IS200TFBAH1A CPUs (redundant), four IS200BPIHH1A analog input modules (for pressure/temperature monitoring), one IS200TRLYH2C relay module (for valve control), and one IS200TDBTH6A data buffer module. Power is supplied by two redundant IS200CPFPG1A modules—if one fails, IS200CABPG1B seamlessly switches to the backup. During a recent grid disturbance, the backplane’s 1 Gbps bus ensured the CPU received real-time pressure data from IS200BPIHH1A in 5 ms, allowing it to adjust fuel flow and prevent a turbine trip.

In an oil refinery’s hydrocracker unit (Class 1 Division 2 hazardous area), IS200CABPG1B (housed in an explosion-proof enclosure) powers and connects 6 critical modules: two IS200BPIHH1A modules (for reactor pressure/temperature), two IS200TRLYH1C modules (for emergency shutdown valves), one IS200TFBAH1A CPU, and one IS200EACFG2A configuration module. The backplane’s per-slot circuit breakers proved invaluable when a IS200TRLYH1C module developed a coil short—only that slot’s breaker tripped, keeping the reactor pressure monitoring modules online. This prevented an unplanned shutdown that would have cost the refinery $150,000 in lost production.

Related model recommendations

IS200CPFPG1A: GE’s power supply filter module. Primary power source for IS200CABPG1B—provides clean 24 V DC power with noise suppression, ensuring stable distribution to slots.

IS200HFPAG2A: GE’s high-power backplane supply (10 A). Complements IS200CABPG1B for systems with 8 high-current modules (e.g., multiple IS200TRLYH2C units) exceeding IS200CPFPG1A’s 5 A capacity.

IS200BPIHH1A: GE’s high-precision analog input module. A common slot-mounted module for IS200CABPG1B—relies on the backplane for power and data transmission to the CPU.

IS200TFBAH1A: GE’s Mark VIe CPU module. Mounts in IS200CABPG1B’s slot to act as the system controller—uses the backplane’s 1 Gbps bus to communicate with I/O modules.

IS200TRLYH2C: GE’s intermediate relay module. Slot-compatible with IS200CABPG1B—receives power and control signals via the backplane for valve actuation.

IS200EACFG2A: GE’s configuration module. Stores IS200CABPG1B’s slot configuration and module parameters—enables quick recovery after backplane replacement.

IS200JGNDG1A: GE’s grounding module. Enhances IS200CABPG1B’s isolation by providing a low-impedance ground path—critical for high-noise environments (e.g., near VFDs).

IS200TDBTH6A: GE’s data buffer module. Mounts in IS200CABPG1B to log data from I/O modules—uses the backplane’s high-speed bus to avoid data bottlenecks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200CABPG1B, power off all Mark VIe components and use ESD-safe tools. Mount the backplane in a 19-inch standard rack, ensuring 15 cm clearance above/below for heat dissipation. Connect dual 24 V DC power inputs (from IS200CPFPG1A or IS200HFPAG2A) to the backplane’s primary/backup terminals—verify reverse polarity protection (backplane will not power on if wired incorrectly). Label each slot (e.g., “Slot 1: CPU”, “Slot 2: Analog Input”) to avoid module misplacement.

Maintenance suggestions: Inspect IS200CABPG1B’s slot status LEDs weekly—green = normal power/communication, amber = module fault, red = slot power failure. Every 6 months, test dual power input switching by temporarily disconnecting the primary supply—ensure the backplane switches to backup within 100 ms. Clean the backplane’s ventilation grilles annually to prevent overheating. For hot-swap replacement of modules (e.g., IS200BPIHH1A), press the slot’s “release” button before removing the module—never force modules into slots. If a slot’s circuit breaker trips, resolve the module fault (e.g., short circuit) before resetting the breaker. Always use GE-approved modules to avoid slot damage.

Service and guarantee commitment

IS200CABPG1B comes with a 4-year standard warranty from GE, covering defects in materials (e.g., power distribution circuits, communication bus) and workmanship—longer than most backplane modules. If the backplane fails within this period (e.g., slot power loss, communication bus failure), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free on-site support for reinstallation and reconfiguration.

GE offers 24/7 global support for IS200CABPG1B: Certified Mark VIe engineers assist with rack mounting, power redundancy testing, and bus troubleshooting via phone, email, or remote access (GE Remote Support Portal). Customers gain access to IS200CABPG1B’s wiring diagrams, slot compatibility guides, and EMC test reports. For mission-critical systems (e.g., nuclear power, offshore turbines), GE provides extended warranties (up to 6 years) and semi-annual on-site backplane audits—ensuring compliance with IEC 61010-1 standards and 99.999% operational reliability.