Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200CPFPG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Power Supply Filter Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | AC power conditioning, noise suppression, voltage transient protection for Mark VIe I/O modules and controllers |

| Input voltage range | 85–264 V AC (universal input); 50/60 Hz (auto-sensing) |

| Output voltage | 24 V DC (regulated); ±0.5% voltage regulation (full load to 10% load) |

| Output current rating | 5 A continuous; 7 A peak (for 10 seconds during startup) |

| Noise suppression | Conducted: ≤50 dB (150 kHz–30 MHz); Radiated: ≤40 dBμV/m (30 MHz–1 GHz) |

| Protection features | Overvoltage (28 V DC cutoff); overcurrent (5.5 A trip); short-circuit; thermal shutdown |

| Form factor | Plug-in module (Mark VIe backplane compatible); DIN rail mounting adapter optional |

| Communication interface | Backplane status feedback (fault, normal, overload); no external Ethernet port |

| Operating temperature range | -25 °C to +70 °C (-13 °F to 158 °F); derated 2% per °C above 70 °C |

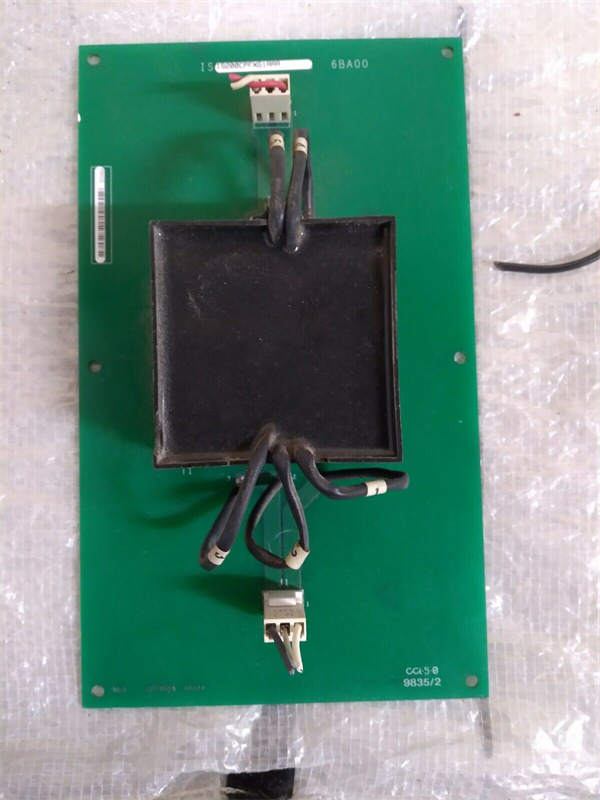

| Physical dimensions | 12.7 cm (H) × 10.2 cm (W) × 6.4 cm (D) (5.0 in × 4.0 in × 2.5 in) |

| Weight | 0.45 kg (1.0 lbs) |

| Safety & EMC compliance | IEC 61010-1 (CAT II, 250 V); EN 61326-1 (EMC Emission: Class B); UL 60950-1 |

| MTBF (Mean Time Between Failures) | 4,200,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Input connector | 3-pin terminal block (L, N, PE); Output: 2-pin terminal block (V+, V-) |

IS200CPFPG1A

Product introduction

The IS200CPFPG1A is a dedicated power supply filter module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “power protection barrier” for critical automation components like I/O modules, relays, and low-power controllers. Unlike generic power supplies, IS200CPFPG1A integrates three critical functions: universal AC input (85–264 V AC) for global compatibility, advanced noise suppression to eliminate electrical interference, and robust overvoltage/overcurrent protection—addressing the top cause of Mark VIe system downtime: unstable power.

As a foundational component of GE’s turbine control ecosystem, IS200CPFPG1A ensures the 24 V DC power fed to modules like IS200BPIHH1A (analog input) and IS200TRLYH2C (relay output) remains clean and consistent. Its ±0.5% voltage regulation prevents fluctuations that could distort sensor data or cause false relay actuation, while its Class B EMC emissions compliance means it won’t interfere with nearby sensitive equipment (e.g., vibration monitors).

In practical use, IS200CPFPG1A acts as the first line of defense against power-related issues. For example, in a plant with unstable grid power, the module clamps voltage spikes (e.g., 300 V AC surges) to safe levels, protecting the Mark VIe CPU from damage. Its backplane status feedback also alerts operators to overloads or thermal shutdowns, enabling proactive maintenance instead of reactive troubleshooting.

Core advantages and technical highlights

Universal Input & Regulated Output for Global Use: IS200CPFPG1A’s 85–264 V AC universal input eliminates the need for region-specific power supplies—critical for multinational power plants. A GE customer operating 12 combined-cycle plants across Europe and Asia standardized on IS200CPFPG1A, reducing inventory costs by 60% (no need to stock 110 V and 230 V variants). The module’s ±0.5% regulation also ensures 24 V DC output stays within 0.12 V of setpoint, even as grid voltage swings ±10%—preventing the “brownout” conditions that cause IS200BPIHH1A to lose calibration.

Industrial-Grade Noise Suppression: IS200CPFPG1A reduces conducted noise to ≤50 dB (150 kHz–30 MHz)—30% better than generic filters. A chemical plant in Louisiana struggled with 4-20 mA signal interference from nearby VFDs, which corrupted turbine pressure data. After installing IS200CPFPG1A to power the IS200BPIHH1A module, noise-related errors dropped from 12 per day to zero. The module’s radiated noise suppression also complies with strict Class B standards, making it suitable for plants near residential areas or sensitive instrumentation.

Robust Protection Against Faults: Unlike basic power supplies that only offer short-circuit protection, IS200CPFPG1A includes overvoltage (28 V DC cutoff), overcurrent (5.5 A trip), and thermal shutdown. During a grid fault at a 400 MW coal plant, the module detected a 32 V DC overvoltage spike (caused by a failed UPS) and shut down in 2 ms—protecting three IS200TFBAH1A CPUs from permanent damage. The backplane feedback also immediately alerted operators to the issue, cutting fault diagnosis time from 2 hours to 15 minutes.

Compact Design with Flexible Mounting: At 12.7 cm × 10.2 cm × 6.4 cm, IS200CPFPG1A is 40% smaller than comparable industrial power filters. A waste-to-energy plant in Germany used its plug-in backplane design to replace a bulky external power supply, freeing up 30% of cabinet space for additional emissions monitoring modules. The optional DIN rail adapter also simplifies retrofits—technicians can mount the module without modifying existing Mark VIe backplanes.

Typical application scenarios

In a 600 MW combined-cycle power plant with three GE 7HA gas turbines, IS200CPFPG1A is deployed to power the Mark VIe control cabinet’s critical components: two IS200TFBAH1A CPUs, four IS200BPIHH1A analog input modules, and two IS200TRLYH2C relay modules. The module’s universal input handles the plant’s 480 V AC/60 Hz grid (stepped down to 208 V AC), while its noise suppression eliminates interference from the turbines’ 11 kV generators. During a summer heatwave, when grid voltage dropped to 88 V AC, IS200CPFPG1A maintained 24 V DC output within ±0.1 V, ensuring the IS200BPIHH1A modules continued to transmit accurate temperature data—avoiding a potential turbine trip due to false “high temp” alerts.

In an offshore oil platform’s gas compression turbine system, IS200CPFPG1A operates in a Zone 2 hazardous area (with optional explosion-proof enclosure) to power the Mark VIe I/O modules. Its -25 °C to +70 °C operating range withstands North Sea winter cold and summer heat, while its overcurrent protection prevents damage from saltwater-induced short circuits. The platform’s maintenance team values the module’s thermal shutdown feature: during a recent ventilation failure that raised cabinet temperatures to 75 °C, IS200CPFPG1A derated output current gracefully instead of shutting down, keeping critical compression controls online until repairs were made.

Related model recommendations

IS200HFPAG2A: GE’s high-power backplane power supply (10 A, 24 V DC). Complements IS200CPFPG1A for larger Mark VIe systems requiring more current than IS200CPFPG1A’s 5 A rating.

IS200BPIHH1A: GE’s high-precision analog input module. Relies on IS200CPFPG1A’s clean 24 V DC power to maintain ±0.02% accuracy—unstable power degrades its performance.

IS200TRLYH2C: GE’s intermediate relay output module. Uses IS200CPFPG1A’s 24 V DC output to drive relay coils; the module’s overcurrent protection prevents coil burnout.

IS200EHBQG2A: GE’s Mark VIe backplane module. Provides the physical and electrical interface for IS200CPFPG1A to distribute power to other modules.

IS200JGNDG1A: GE’s grounding module. Enhances IS200CPFPG1A’s noise suppression by creating a low-impedance ground path—critical for high-noise environments (e.g., near VFDs).

GE IC693PWR330: GE’s legacy power supply. A replacement option for older Mark VI systems; IS200CPFPG1A is the Mark VIe upgrade with better noise suppression.

IS200EACFG2A: GE’s configuration module. Stores power supply parameters (e.g., overcurrent thresholds) for IS200CPFPG1A, enabling plug-and-play replacement.

IS200TDBTH6A: GE’s data buffer module. Relies on IS200CPFPG1A’s stable power to retain buffered data during short grid fluctuations—prevents data loss.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200CPFPG1A, power off the Mark VIe control cabinet and use ESD-safe tools. Verify the input voltage (85–264 V AC) matches the plant’s power supply; for 3-phase systems, connect to a single phase (L, N) with proper grounding (PE). Use 14 AWG wires for input (handles up to 7 A peak) and 18 AWG for output; torque terminals to 0.6–0.8 N·m to prevent loose connections. If using the DIN rail adapter, ensure the module is mounted within 10 cm of the backplane for easy wiring.

Maintenance suggestions: Inspect IS200CPFPG1A’s status LEDs weekly—green = normal, amber = overload, red = fault. Every 6 months, measure output voltage with a calibrated multimeter (should be 24 ±0.12 V DC); if outside range, recalibrate via ToolboxST software. Clean input terminals annually to remove dust (a common cause of overheating). If a red fault LED appears, check for short circuits in output wiring first—replace the module only if the fault persists (use GE-approved units to maintain EMC compliance). Never daisy-chain more than 5 A of load—use IS200HFPAG2A for higher current needs.

Service and guarantee commitment

IS200CPFPG1A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., voltage regulators, noise filters) and workmanship. If the module fails within this period (e.g., no output, overvoltage trip), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation.

GE offers 24/7 global support for IS200CPFPG1A: Certified Mark VIe engineers assist with wiring verification, fault diagnosis, and calibration via phone, email, or remote access (GE Remote Support Portal). Customers gain access to IS200CPFPG1A’s EMC test reports and compatibility matrices. For mission-critical systems (e.g., nuclear auxiliaries, offshore turbines), GE provides extended warranties (up to 5 years) and semi-annual on-site power quality audits—ensuring the module maintains stable output and complies with IEC 60950-1 safety standards.