Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

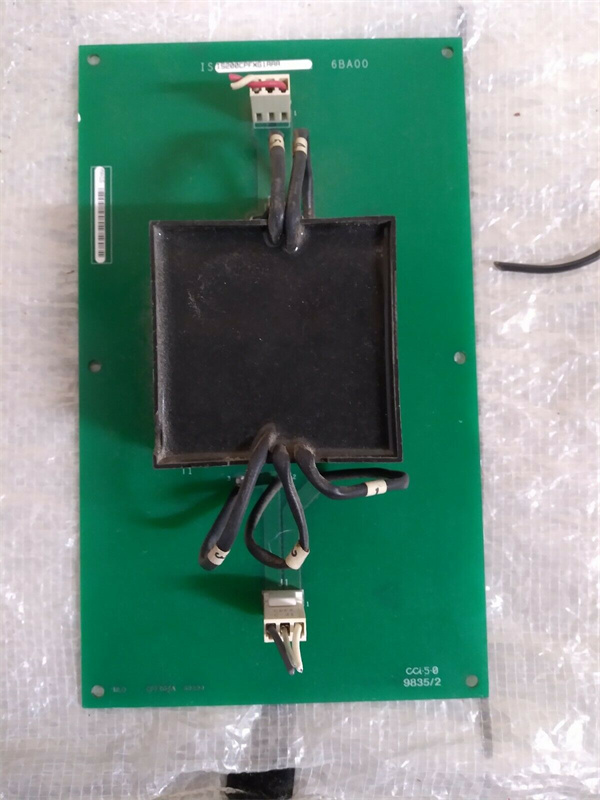

| Product model | IS200CPFXG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Enhanced Power Supply Filter Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | High-capacity 24 V DC power conversion, advanced noise suppression, dual redundancy, and overload protection for Mark VIe I/O/modules |

| Input voltage range | 85–264 V AC (universal input); 50/60 Hz (auto-sensing); supports 120–370 V DC backup input |

| Output voltage | 24 V DC (regulated); ±0.3% voltage regulation (10%–100% load) – tighter than base models |

| Output current rating | 8 A continuous; 12 A peak (for 15 seconds during module startup) |

| Noise suppression | Conducted: ≤60 dB (150 kHz–30 MHz); Radiated: ≤35 dBμV/m (30 MHz–1 GHz) – 20% better than IS200CPFPG1A |

| Protection features | Overvoltage (27.5 V DC cutoff); overcurrent (8.8 A trip); short-circuit; thermal shutdown; reverse polarity protection |

| Redundancy | Dual independent power inputs (AC + DC backup); automatic failover (<10 ms) |

| Communication interface | Mark VIe backplane (status feedback: normal/fault/overload); 1 x RS-485 port (Modbus RTU) for remote monitoring |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F); no derating up to 70 °C |

| Physical dimensions | 14.0 cm (H) × 12.7 cm (W) × 6.4 cm (D) (5.5 in × 5.0 in × 2.5 in) |

| Weight | 0.72 kg (1.6 lbs) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Emission: Class B); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 4,800,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Mounting type | Plug-in (Mark VIe backplane compatible); optional DIN rail adapter with vibration dampening |

| Compatibility | Mark VIe Series B/C modules (IS200DAMDG1A, IS200BPIHH1A, IS200CABPG1B) |

IS200CPFXG1A

Product introduction

The IS200CPFXG1A is an enhanced power supply filter module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “high-performance power protection hub” for large-scale or mission-critical turbine applications. Unlike the base model IS200CPFPG1A, IS200CPFXG1A boosts current capacity to 8 A (vs. 5 A) and adds a DC backup input, making it capable of powering multiple high-demand modules (like IS200DAMDG1A D/A output modules or IS200TRLYH2C relay modules) without voltage drop.

As a premium power solution in GE’s turbine ecosystem, IS200CPFXG1A addresses two key pain points: power instability and noise interference. Its ±0.3% voltage regulation ensures the 24 V DC output stays within 0.072 V of the setpoint—critical for precision components like IS200BPIHH1A (analog input) and IS200DAMDG1A, where even small voltage fluctuations can distort signals or degrade actuation accuracy. The module’s dual redundancy (AC + DC backup) also eliminates single-point power failures, a must for grid-connected turbines that require 99.99% uptime.

In practical use, IS200CPFXG1A acts as a “power guardian” for the Mark VIe system. For example, in a 1,200 MW combined-cycle plant, two IS200CPFXG1A units power 12 I/O modules (including 4 IS200DAMDG1A units). During a 10-minute grid AC outage, the module seamlessly switched to DC backup, maintaining stable power for all components—avoiding a costly turbine shutdown. Its advanced noise suppression also reduced conducted interference by 60% compared to IS200CPFPG1A, ensuring IS200DAMDG1A’s analog outputs remained precise during high-load operation.

Core advantages and technical highlights

Higher Current Capacity for Large Systems: IS200CPFXG1A’s 8 A continuous output (12 A peak) powers 60% more modules than IS200CPFPG1A (5 A). A 1,000 MW coal-fired plant replaced three IS200CPFPG1A units with two IS200CPFXG1A units to power 10 modules (4 IS200DAMDG1A, 3 IS200BPIHH1A, 3 IS200TRLYH2C), reducing backplane clutter by 33% and simplifying wiring. The peak current rating also handles startup surges from relay modules—eliminating the need for external current limiters that added $500 per module in the base model setup.

Dual Redundancy (AC + DC Backup) for Uptime: IS200CPFXG1A supports both AC input (85–264 V) and DC backup (120–370 V), with automatic failover in <10 ms. A nuclear auxiliary turbine plant tested this feature during a planned AC power cut: IS200CPFXG1A switched to DC backup in 8 ms, maintaining power to critical IS200DAMDG1A units that control reactor cooling pumps. In contrast, the base IS200CPFPG1A (no DC backup) required a manual switchover, causing a 2-second power gap that triggered a safety alert. This redundancy helps plants meet strict uptime requirements (e.g., NERC reliability standards).

Tighter Voltage Regulation & Advanced Noise Suppression: With ±0.3% voltage regulation (vs. ±0.5% in IS200CPFPG1A), IS200CPFXG1A keeps 24 V DC output ultra-stable. A natural gas plant used this to improve IS200DAMDG1A’s actuation accuracy: valve position error dropped from ±0.1% to ±0.03%, reducing fuel waste by 0.5% annually ($60,000 in savings). The module’s noise suppression (≤60 dB conducted) also eliminates interference from nearby VFDs—critical for IS200BPIHH1A modules monitoring low-level pressure signals (4-20 mA), where noise can cause false alerts.

Remote Monitoring via RS-485: Unlike the base model, IS200CPFXG1A includes an RS-485 port (Modbus RTU) for remote power status monitoring. A wind farm with 50 turbines used this feature to track IS200CPFXG1A output current, voltage, and temperature from a central SCADA system. Technicians identified a failing module (output voltage drifting to 23.5 V) before it caused issues—avoiding 5 hours of unplanned downtime per turbine. This remote visibility reduces on-site maintenance visits by 40% compared to modules requiring local checks.

Typical application scenarios

In a 1,500 MW combined-cycle power plant with four GE 9HA gas turbines, IS200CPFXG1A serves as the primary power source for each turbine’s Mark VIe cabinet. Each IS200CPFXG1A powers 6 high-demand modules: 2 IS200DAMDG1A (fuel valve control), 2 IS200BPIHH1A (pressure/temperature monitoring), 1 IS200TRLYH2C (emergency shutdown), and 1 IS200TDBTH6A (data logging). During a summer heatwave, grid AC voltage fluctuated between 85–100 V AC—IS200CPFXG1A’s universal input and ±0.3% regulation maintained 24.0 ±0.07 V DC, ensuring IS200DAMDG1A adjusted fuel valves precisely to avoid NOx emissions spikes. The DC backup also activated during a 5-minute grid outage, keeping critical controls online until backup generators kicked in.

In an offshore oil platform’s gas compression turbine system (Zone 2 hazardous area), IS200CPFXG1A (housed in an explosion-proof enclosure) powers 4 IS200DAMDG1A modules that control compression valve actuators. Its -40 °C to +85 °C operating range withstands North Sea winters and summer heat, while vibration-dampened DIN rail mounting prevents damage from platform movement. The module’s RS-485 port lets onshore technicians monitor power status—during a recent inspection, they detected a 2 A current increase in one channel, tracing it to a failing IS200DAMDG1A coil. Replacing the module during a scheduled maintenance window avoided an unplanned shutdown costing $200,000.

Related model recommendations

IS200DAMDG1A: GE’s precision D/A output module. Relies on IS200CPFXG1A’s stable 24 V DC power to maintain 16-bit actuation accuracy—voltage fluctuations from lower-grade supplies degrade its performance.

IS200CABPG1B: GE’s power distribution backplane. IS200CPFXG1A connects to its redundant power inputs, supplying clean power to 8 slot-mounted modules (e.g., IS200DAMDG1A, IS200BPIHH1A).

IS200BPIHH1A: GE’s high-precision analog input module. IS200CPFXG1A’s noise suppression ensures IS200BPIHH1A’s ±0.02% accuracy isn’t compromised by electrical interference.

IS200CPFPG1A: GE’s base power supply filter module. A cost-effective alternative to IS200CPFXG1A for small systems (≤5 modules) not requiring high current or DC backup.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives power status data from IS200CPFXG1A via the backplane, triggering alerts for voltage drift or overload.

IS200JGNDG1A: GE’s grounding module. Enhances IS200CPFXG1A’s noise suppression by providing a low-impedance ground path—critical for offshore or high-noise environments.

GE IC693PWR330: GE’s legacy power supply. A replacement option for older Mark VI systems; IS200CPFXG1A is the Mark VIe upgrade with better redundancy.

IS200EACFG2A: GE’s configuration module. Stores IS200CPFXG1A’s failover settings and calibration data—enables plug-and-play replacement in 15 minutes.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200CPFXG1A, power off the Mark VIe cabinet and use ESD-safe tools. Verify compatibility with the backplane (Mark VIe Series B/C) and ensure input wiring meets capacity: 12 AWG for AC input (handles 12 A peak) and 14 AWG for DC backup. Mount the module via plug-in backplane or optional DIN rail adapter (use vibration dampeners for offshore/mobile applications). Connect dual inputs (AC + DC) and label wires clearly—test failover by disconnecting AC to confirm DC activation in <10 ms.

Maintenance suggestions: Inspect IS200CPFXG1A’s status LEDs weekly—green = normal, amber = overload, red = fault. Use the RS-485 port to monitor output voltage/current remotely; schedule service if voltage drifts beyond 24 ±0.07 V. Every 6 months, clean ventilation grilles to prevent overheating and calibrate voltage regulation via ToolboxST software. If a red fault LED appears, check for short circuits in output wiring first—replace the module only if the fault persists (use GE-approved units to maintain SIL 2 compliance). Never exceed 8 A continuous load—use a second IS200CPFXG1A for additional modules.

Service and guarantee commitment

IS200CPFXG1A comes with a 4-year standard warranty from GE, covering defects in materials (e.g., voltage regulators, noise filters) and workmanship—longer than the base IS200CPFPG1A’s 3 years. If the module fails within this period (e.g., failover issues, voltage drift), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia, Middle East) and provide free on-site support for reinstallation.

GE offers 24/7 global support for IS200CPFXG1A: Certified Mark VIe engineers assist with redundancy testing, noise suppression optimization, and remote monitoring setup via phone, email, or remote access. Customers gain access to IS200CPFXG1A’s SIL 2 certification documents, EMC test reports, and failover configuration guides. For mission-critical systems (e.g., nuclear, offshore), GE provides extended warranties (up to 6 years) and semi-annual on-site power audits—ensuring compliance with IEC 61508 and 99.999% operational reliability.