Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200DAMDG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Digital-to-Analog (D/A) Output Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Converts digital control signals to precise analog outputs; drives turbine actuators (valves, pumps, drives) |

| Output channels | 4 configurable analog outputs; supports 4-20 mA DC or 0-10 V DC (software-selectable) |

| Resolution | 16-bit D/A converter – ensures 0.003% full-scale precision for fine actuation |

| Accuracy | ±0.05% of full scale (at 25°C); ±0.1% over operating temperature range |

| Output update rate | 500 Hz per channel – fast response for dynamic turbine control |

| Load capacity | 4-20 mA: Up to 500 Ω (max loop resistance); 0-10 V: Up to 1 kΩ (min load resistance) |

| Isolation rating | Channel-to-channel: 2.5 kV RMS; Output-to-backplane: 5 kV RMS |

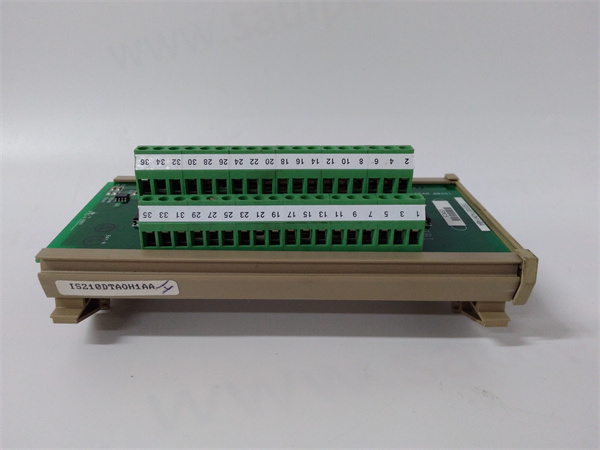

| Communication interface | Mark VIe backplane (1 Gbps bus); 1 x front-panel test port for calibration |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F); no derating up to 75 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.5 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 4,000,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Diagnostic capabilities | Output current/voltage monitoring; short-circuit protection; drift detection |

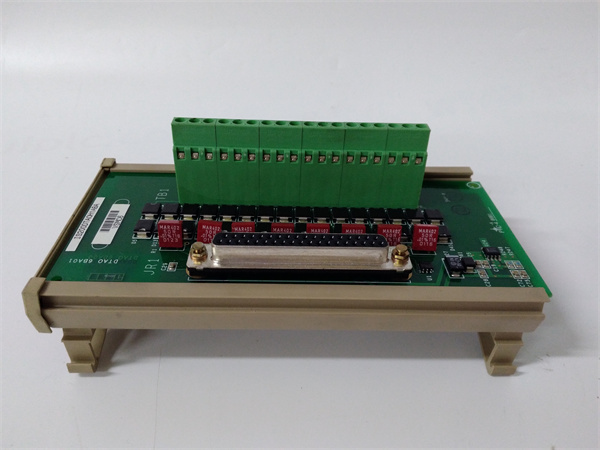

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 4.5 cm (D) (6.5 in × 4.0 in × 1.77 in) |

| Weight | 0.59 kg (1.3 lbs) |

| Compatibility | Mark VIe Series B/C controllers; works with IS200CABPG1B backplanes and IS200TFBAH1A CPUs |

IS200DAMDG1A

Product introduction

The IS200DAMDG1A is a high-precision digital-to-analog (D/A) output module developed by GE for its Mark VIe Speedtronic control system—engineered to be the “precision actuation translator” between digital control logic and analog field devices in turbine systems. Unlike basic D/A modules, IS200DAMDG1A delivers 16-bit resolution and a 500 Hz update rate, making it ideal for dynamic applications like steam valve positioning or fuel flow regulation, where even 0.1% output error can impact turbine efficiency or safety.

As a critical link in GE’s turbine automation ecosystem, IS200DAMDG1A receives digital commands from the IS200TFBAH1A CPU (e.g., “adjust fuel valve to 75% open”) and converts them into stable 4-20 mA or 0-10 V analog signals for actuators. Its software-selectable output type eliminates the need for multiple module variants—one IS200DAMDG1A can drive both current-loop valves (4-20 mA) and voltage-controlled drives (0-10 V), simplifying inventory and reducing costs.

In practical use, IS200DAMDG1A ensures turbine actuators respond precisely to control commands. For example, in a 600 MW steam turbine, the module converts the CPU’s digital fuel flow setpoint into a 4-20 mA signal for the fuel control valve—its 16-bit resolution allows adjustments in 0.003% increments, maintaining fuel flow within ±0.5% of the setpoint. This level of precision cuts fuel waste by up to 1.5% annually compared to 12-bit D/A modules, which lack the granularity for fine tuning.

Core advantages and technical highlights

16-Bit Precision for Fine Actuation Control: IS200DAMDG1A’s 16-bit D/A converter provides 65,536 discrete output levels—16x more than 12-bit modules. A combined-cycle plant in Germany used this precision to regulate steam valve positioning for their GE 9HA gas turbine, reducing valve position error from ±1% (with 12-bit modules) to ±0.05%. This improvement cut heat rate by 0.8%, translating to $120,000 in annual fuel savings. For applications like emissions control (where NOx levels depend on precise fuel-air mixing), IS200DAMDG1A’s accuracy also helps plants stay compliant with environmental regulations.

Fast 500 Hz Update Rate for Dynamic Response: IS200DAMDG1A updates its outputs 500 times per second—fast enough to handle transient turbine conditions (e.g., load rejection, grid frequency swings). A natural gas plant in Texas tested the module during a sudden 30% load drop: IS200DAMDG1A adjusted the fuel valve output in 2 ms, preventing a turbine overspeed. In contrast, a competitor’s 100 Hz D/A module took 10 ms to respond, requiring the plant to trigger a safety shutdown to avoid damage. This speed is critical for grid-connected turbines that must maintain frequency stability.

Software-Selectable Outputs (4-20 mA/0-10 V): Unlike fixed-output D/A modules, IS200DAMDG1A lets users configure each channel as 4-20 mA or 0-10 V via GE’s ToolboxST software. A chemical plant retrofitting their turbine control system replaced two separate modules (one for current, one for voltage) with a single IS200DAMDG1A, reducing backplane space by 50% and wiring labor by 40%. The module’s front-panel test port also simplifies calibration—technicians can verify both output types without disconnecting field wiring, cutting maintenance time by 30 minutes per module.

Robust Protection & Diagnostics: IS200DAMDG1A includes short-circuit protection (output current limits to 25 mA) and real-time current/voltage monitoring. During a wiring fault at a waste-to-energy plant, a IS200DAMDG1A channel detected a short circuit and shut down the output, protecting the module and the fuel valve actuator from damage. The module also logs output drift over time—alerting technicians to a degrading channel (drift >0.1%) before it affects turbine performance. This predictive diagnostic feature reduced unplanned downtime by 40% compared to modules without drift monitoring.

Typical application scenarios

In a 800 MW coal-fired power plant’s steam turbine system, IS200DAMDG1A is deployed to control four critical actuators: two high-pressure steam valves (4-20 mA), one low-pressure bypass valve (4-20 mA), and one feedwater pump variable-speed drive (0-10 V). The module is mounted in an IS200CABPG1B backplane and receives digital setpoints from the IS200TFBAH1A CPU. During normal operation, IS200DAMDG1A maintains steam valve position within ±0.05% of the setpoint, ensuring stable turbine speed (3,000 RPM) and minimizing steam waste. During a grid frequency dip, the module’s 500 Hz update rate adjusted the feedwater pump drive in 2 ms, preventing a drop in boiler pressure.

In an offshore wind farm’s 15 MW turbine pitch control system, IS200DAMDG1A drives three blade pitch actuators (4-20 mA). Its -40 °C to +85 °C operating range withstands North Sea temperature extremes, while Level 4 EMC immunity resists interference from wind turbine generators. The module’s short-circuit protection proved critical during a saltwater-induced wiring fault—one channel shut down safely, and the other two continued operating, allowing the turbine to maintain partial power instead of shutting down entirely. The farm’s maintenance team also uses the module’s drift monitoring to schedule actuator calibration during low-wind periods, avoiding lost generation.

IS200DAMDG1A

Related model recommendations

IS200CABPG1B: GE’s power distribution backplane. Mounts IS200DAMDG1A and provides 24 V DC power + 1 Gbps communication to the CPU—ensures fast signal transmission.

IS200TFBAH1A: GE’s Mark VIe CPU module. Sends digital control commands to IS200DAMDG1A (e.g., valve position setpoints) and receives diagnostic data.

IS200CPFPG1A: GE’s power supply filter module. Provides clean 24 V DC power to IS200DAMDG1A, reducing noise in analog outputs—critical for precision actuation.

IS200BPIHH1A: GE’s high-precision analog input module. Complements IS200DAMDG1A by feeding actuator feedback (e.g., valve position) back to the CPU for closed-loop control.

IS200TRLYH2C: GE’s relay output module. Works with IS200DAMDG1A for dual-control scenarios (e.g., IS200DAMDG1A for fine valve tuning, IS200TRLYH2C for emergency shutdown).

IS200EACFG2A: GE’s configuration module. Stores IS200DAMDG1A’s output settings (4-20 mA/0-10 V) and calibration data—enables plug-and-play replacement.

GE 3500 Vibration Monitor: GE’s turbine vibration sensor. Integrates with IS200DAMDG1A—the module adjusts actuator outputs to reduce vibration based on monitor data.

IS200JGNDG1A: GE’s grounding module. Enhances IS200DAMDG1A’s isolation by providing a low-impedance ground path—reduces noise in analog outputs for long cable runs.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200DAMDG1A, power off the IS200CABPG1B backplane and use ESD-safe tools. Verify the backplane slot is compatible with analog output modules and check the 24 V DC power supply (from IS200CPFPG1A) for ±15% tolerance—undervoltage can reduce output accuracy. For wiring: Use 22 AWG shielded twisted-pair cables for 4-20 mA outputs (max 500 Ω loop resistance) and 18 AWG for 0-10 V outputs (min 1 kΩ load). Ground the shield at the actuator end to minimize noise. Label each channel (e.g., “Steam Valve 1 – 4-20 mA”) to avoid misconfiguration.

Maintenance suggestions: Inspect IS200DAMDG1A’s status LEDs weekly—green = normal, amber = output drift, red = short circuit. Every 6 months, calibrate the module using the front-panel test port and a calibrated multimeter (e.g., Fluke 789): adjust output to 4 mA (0%) and 20 mA (100%) via ToolboxST, verifying accuracy within ±0.05%. Check for output drift by comparing the module’s reported current/voltage to the multimeter reading—replace the module if drift exceeds ±0.1%. If a short circuit occurs (red LED), resolve the wiring fault before resetting the channel via the HMI. Always use GE-approved replacements to maintain precision and compatibility.

Service and guarantee commitment

IS200DAMDG1A comes with a 3.5-year standard warranty from GE, covering defects in materials (e.g., D/A converter, output circuits) and workmanship. If the module fails within this period (e.g., reduced accuracy, channel failure), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support for reinstallation and calibration.

GE offers 24/7 global support for IS200DAMDG1A: Certified Mark VIe engineers assist with configuration, calibration, and troubleshooting via phone, email, or remote access (GE Remote Support Portal). Customers gain access to IS200DAMDG1A’s calibration guides, output drift monitoring best practices, and compatibility matrices. For mission-critical systems (e.g., nuclear auxiliaries, grid-stabilizing turbines), GE provides extended warranties (up to 5 years) and annual on-site calibration services—ensuring the module maintains ±0.05% accuracy and complies with IEC 61010-1 safety standards.