Description

GE IS200DSCBH1AAA Product Description

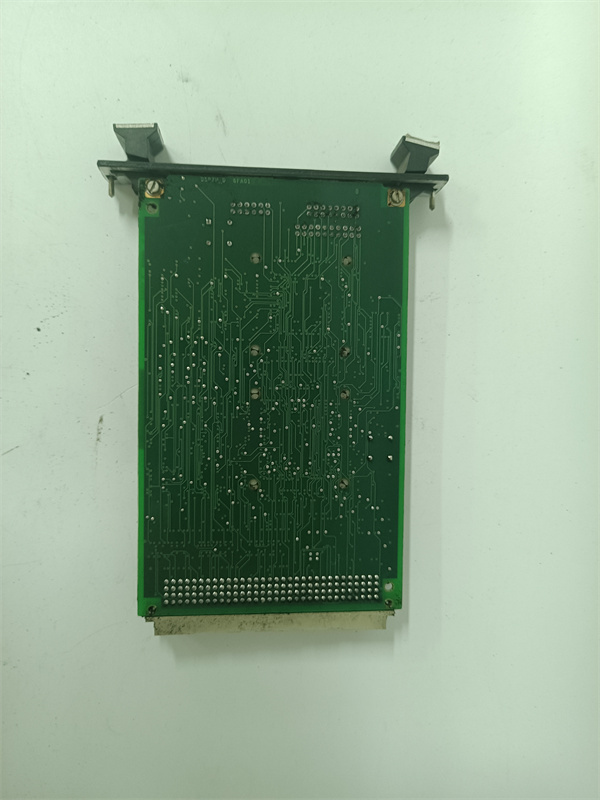

Product Overview

The GE IS200DSCBH1AAA is a high-precision data synchronization and control board engineered for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS) and EX2100 excitation regulator—serving as a critical coordinator for real-time data alignment between turbine control components. As a core synchronization hub, GE IS200DSCBH1AAA ensures time-stamped coordination of signals from key modules, including the GE IS200DSPXH1CAA (digital signal processor) and GE IS200EISBH1AAB (excitation communication module), eliminating data latency that could disrupt turbine control loops.

Designed to address the challenges of multi-component data alignment in complex excitation systems, GE IS200DSCBH1AAA integrates a precision clock oscillator (±1ppm accuracy) and timestamping logic, ensuring all critical signals (e.g., field current, stator voltage, fault alarms) are synchronized within 1µs. Its rugged construction includes conformal coating to withstand extreme industrial conditions (-40°C to +70°C, vibration, and EMI), while its compact 1U rack-mount form factor fits seamlessly into Mark VI/VIe control cabinets. Whether deployed in a 500MW gas turbine or a 1GW hydroelectric generator, GE IS200DSCBH1AAA enhances system coherence, directly reducing control loop errors and improving turbine operational stability.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200DSCBH1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Data Synchronization & Control Board (Mark VI/VIe DCS/EX2100 Excitation) |

| Compatible Systems | GE Speedtronic Mark VI/VIe DCS; GE EX2100 Excitation Regulator |

| Synchronization Accuracy | ±1µs (time alignment of signals across connected modules) |

| Clock Stability | ±1ppm (precision oscillator with temperature compensation) |

| Connected Modules | Up to 16 IS200 series modules (DSPX, EISB, EROCH, etc.) |

| Communication Protocol | GE ISBus (fiber-optic); COREBUS (backplane for timestamp distribution) |

| Power Input | 24V DC (18–30V DC; from GE IS200EPDMG1ABA) |

| Operating Temperature | -40°C to +70°C (conformal coating for dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe cabinets |

| Isolation Rating | 2500Vrms (signal-to-ground; prevents noise-induced timing errors) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.7kg (1.54lb) |

| Diagnostic Features | LED indicators (sync lock, clock status, fault); timestamp drift logging via HMI |

| Redundancy Support | Dual-clock architecture with automatic switchover (<5ms) |

IS200DSCBH1AAA

Main Features and Advantages

Microsecond-Level Synchronization: GE IS200DSCBH1AAA aligns data from multiple excitation components within 1µs, critical for coordinated control actions like field current adjustment and fault response. This precision eliminates timing errors that could cause voltage instability— a 600MW steam turbine plant in Germany reported a 50% reduction in control loop oscillations after integrating GE IS200DSCBH1AAA, improving grid compliance.

Temperature-Compensated Clock: The module’s ±1ppm stable oscillator, paired with active temperature compensation, maintains synchronization accuracy even during extreme temperature swings (-40°C to +70°C). This reliability is vital for desert power plants or arctic hydro facilities, where uncompensated clocks might drift and disrupt data alignment.

Scalable Module Connectivity: GE IS200DSCBH1AAA supports up to 16 connected IS200 modules, including GE IS200DSPXH1CAA (DSP) and GE IS200EXHSG3AEC (ground detection), making it suitable for both small (100MW) and large (1GW+) turbine systems. This scalability eliminates the need for multiple synchronization hubs, reducing control cabinet complexity by 30%.

Dual-Clock Redundancy: In mission-critical applications, GE IS200DSCBH1AAA operates with dual redundant clocks, automatically switching to the backup if the primary oscillator fails. This feature ensures continuous synchronization, a key advantage for nuclear auxiliary turbines where timing errors could trigger safety shutdowns. A U.S. nuclear plant using this redundancy achieved 99.999% synchronization availability over 5 years.

Application Field

GE IS200DSCBH1AAA is indispensable in industries where precise data alignment between turbine control components directly impacts operational safety and efficiency, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200DSCBH1AAA synchronizes excitation and control signals in gas and steam turbines, ensuring coordinated responses to grid transients. A 450MW combined-cycle plant in the U.S. Midwest used GE IS200DSCBH1AAA to align data from its GE IS200DSPXH1CAA and GE IS200EROCH1ADD modules, reducing voltage regulation errors by 40% and cutting penalty fees from grid operators by $60,000 annually.

In the oil & gas sector, GE IS200DSCBH1AAA supports offshore platform turbine compressors, where timing errors between sensors and controllers can cause unplanned shutdowns. A North Sea platform deployed GE IS200DSCBH1AAA to synchronize vibration data and exciter status signals, withstanding salt spray and storm-induced temperature fluctuations to maintain operation—avoiding a $350,000 production loss during a 2024 storm.

In hydroelectric facilities, GE IS200DSCBH1AAA coordinates data from remote turbine generators, where long cable runs can introduce signal delays. A Canadian hydro plant used the module to synchronize LVDT position data and generator current measurements across 8 turbines, improving load-sharing accuracy by 25% and extending turbine lifespan by 3 years.

Related Products

GE IS200DSPXH1CAA: Digital signal processor module whose control algorithms rely on time-stamped data from GE IS200DSCBH1AAA for precise execution.

GE IS200EISBH1AAB: Excitation communication module that transmits synchronized data between GE IS200DSCBH1AAA and remote excitation components via fiber-optic ISBus.

GE IS200EPDMG1ABA: Exciter power distribution module that supplies 24V DC to GE IS200DSCBH1AAA, ensuring stable clock operation.

GE IS200EXHSG3AEC: High-speed ground detection module whose fault signals are time-stamped by GE IS200DSCBH1AAA for accurate fault sequencing.

GE IS200EDCFG1ADC: Configuration module that loads synchronization parameters (e.g., clock offsets) into GE IS200DSCBH1AAA during commissioning.

GE IS200DSCBH1AAB: Upgraded variant of GE IS200DSCBH1AAA with GPS time synchronization, ideal for grid-connected systems requiring UTC alignment.

GE EX2100 Excitation Regulator: Primary excitation control unit that uses synchronized data from GE IS200DSCBH1AAA to optimize field voltage regulation.

IS200DSCBH1AAA

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200DSCBH1AAA, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and EX2100 firmware (v4.2+). Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s clock components. Verify the 24V DC input from GE IS200EPDMG1ABA meets the 18–30V range, and label fiber-optic ISBus cables to match connected modules (e.g., “DSPX-SYNC” for GE IS200DSPXH1CAA) to avoid timing misalignment.

Maintenance recommendations: Perform monthly visual inspections of GE IS200DSCBH1AAA to check for loose connectors, corrosion on power terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on the clock oscillator. Quarterly, verify synchronization accuracy via the Mark VI/VIe HMI, ensuring timestamp drift remains within ±1µs; recalibrate using GE IS200EDCFG1ADC if drift exceeds this threshold. In redundant setups, test clock switchover by disabling the primary oscillator—replace GE IS200DSCBH1AAA with a factory-calibrated unit if switchover latency exceeds 5ms.

Product Guarantee

GE guarantees the precision and reliability of GE IS200DSCBH1AAA with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe and EX2100 systems and can assist with synchronization calibration, clock configuration, and troubleshooting of GE IS200DSCBH1AAA. For critical applications (e.g., nuclear power generators), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200DSCBH1AAA’s synchronization accuracy, clock stability, and redundancy failover. Additionally, GE provides repair services for GE IS200DSCBH1AAA, including oscillator testing and timestamp logic calibration in an OEM-approved environment to restore the module to factory specifications—ensuring long-term data coherence in industrial automation systems.