Description

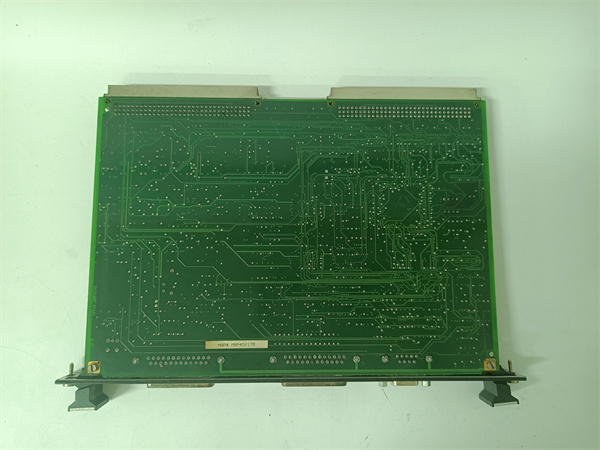

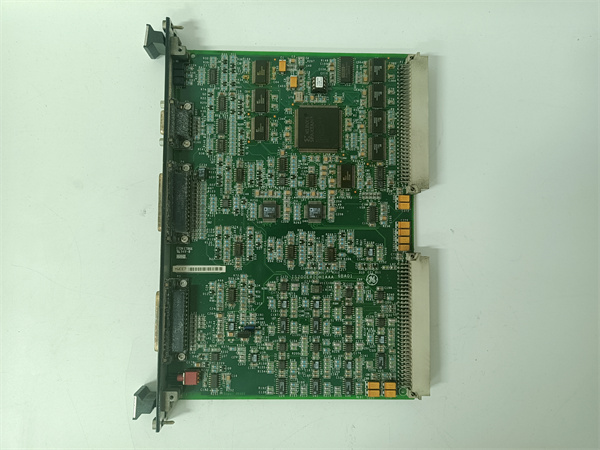

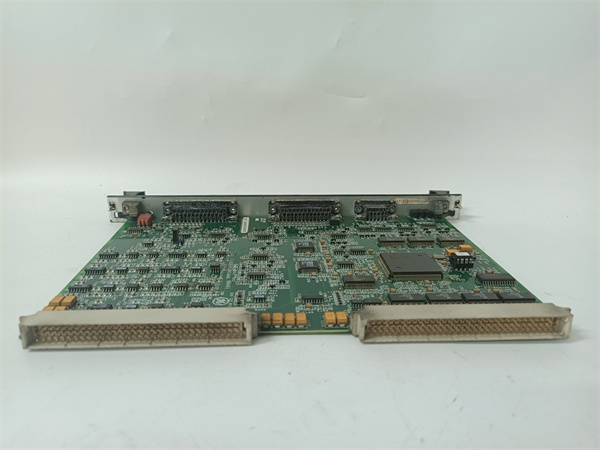

Professional Product Description: GE IS200DSPXH2C

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200DSPXH2C |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Performance Digital Signal Processor Module (for Mark VIe Speedtronic Turbine Control Systems) |

| Processor configuration | Dual-core 32-bit floating-point DSP (200 MHz), with dedicated hardware floating-point unit |

| Data processing capacity | 400 MFLOPS; supports 16-bit/32-bit mixed-precision calculations |

| Memory specifications | 256 MB DDR3 RAM (for real-time data); 128 MB industrial flash (for program storage); 8 MB SRAM (for cache) |

| Input channel configuration | 8 analog input channels (16-bit resolution, 1 MSPS sampling rate); 4 digital/pulse input channels (max 1 MHz) |

| Communication interfaces | 2 x 10/100/1000 Base-T Ethernet ports; 1 x USB 2.0 port; 1 x RS-485 port; Mark VIe backplane interface |

| Programming support | IEC 61131-3 standards (LD, FBD, SFC, ST); GE proprietary advanced turbine control algorithm library |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15% tolerance); maximum current draw of 0.8 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,500,000 hours (per Telcordia SR-332, at 40 °C ambient temperature) |

IS200ERIOH1A

Product introduction

The IS200DSPXH2C is a flagship high-performance digital signal processor module developed by General Electric (GE) exclusively for its Mark VIe Speedtronic turbine control system—the industry-leading platform for large-scale gas, steam, and combined-cycle turbine automation. As the “computational core” of the Mark VIe ecosystem, the IS200DSPXH2C is designed to handle real-time signal processing, execute complex control algorithms, and synchronize data with other system components, making it indispensable for precision control in 700 MW+ utility-scale turbines.

Unlike basic processor modules, the IS200DSPXH2C integrates a dual-core 200 MHz DSP with dedicated floating-point capabilities, enabling it to process multi-channel sensor data (e.g., temperature, pressure, speed) and run advanced control logic (such as adaptive combustion control) with minimal latency. Its robust memory configuration—including high-speed DDR3 RAM and industrial-grade flash—ensures reliable data storage and rapid program execution, even in harsh turbine environments with extreme temperatures and electrical noise.

In GE’s Mark VIe system, the IS200DSPXH2C acts as a bridge between field sensors and the main controller, translating raw data into actionable insights for turbine operation. It plays a critical role in optimizing efficiency, ensuring grid compliance, and enabling predictive maintenance—directly contributing to reduced downtime and lower operational costs for power plants worldwide.

Core advantages and technical highlights

Dual-Core DSP Performance for Real-Time Control: The IS200DSPXH2C’s dual-core 200 MHz floating-point DSP delivers 400 MFLOPS of processing power, a 30% improvement over single-core predecessors. This enables it to handle 8 analog input channels (sampled at 1 MSPS each) and 4 high-frequency pulse inputs simultaneously, while executing complex algorithms like FFT-based vibration analysis and model predictive control (MPC) for turbine speed regulation. For a GE 9HA.04 gas turbine, this performance ensures control loop cycles as short as 1 millisecond—critical for maintaining grid frequency within ±0.02 Hz and preventing overspeed events.

High-Resolution Inputs for Precision Sensing: Equipped with 16-bit analog inputs and 1 MHz digital/pulse inputs, the IS200DSPXH2C captures granular data from turbine sensors (e.g., exhaust gas temperature thermocouples, rotor speed encoders) with exceptional accuracy. Unlike lower-resolution modules (12-bit), its 16-bit inputs reduce measurement error to ±0.0015% of full scale, enabling precise combustion control that minimizes NOₓ emissions while maximizing fuel efficiency. In combined-cycle plants, this precision translates to a 2–3% improvement in overall thermal efficiency.

Redundant Design for Uninterrupted Operation: The IS200DSPXH2C features dual Ethernet ports for redundant network connectivity and a lockstep core architecture that validates computational results in real time—key for safety-critical applications. Its industrial-grade components (rated for -40 °C to +85 °C) and built-in self-test (BIST) functionality ensure reliability in harsh environments, such as offshore platforms or desert power plants. GE’s proprietary fault-detection algorithm also monitors the module’s health, alerting operators to potential issues (e.g., memory degradation) before they impact turbine operation.

Typical application scenarios

In utility-scale gas turbine power plants using GE’s 9HA.04 (730 MW output), the IS200DSPXH2C serves as the primary signal processing unit for turbine control. It collects data from 18 exhaust gas temperature thermocouples, 4 pressure sensors (compressor discharge, turbine inlet), and 2 high-resolution speed encoders (turbine rotor, generator shaft). The IS200DSPXH2C processes this data in real time to execute adaptive combustion control—adjusting fuel flow and air intake to maintain optimal flame temperature, which reduces emissions by 15–20% compared to conventional control systems. During grid load changes, the module’s fast processing enables the turbine to ramp up/down at 5 MW per second, meeting grid demand while avoiding thermal stress on components.

In petrochemical cogeneration plants, the IS200DSPXH2C integrates with GE’s LM2500+ gas turbine (40 MW output) to balance power generation and steam production. It processes steam pressure and flow data from the heat recovery steam generator (HRSG) and adjusts turbine speed to match both electrical load and steam demand. The module’s compatibility with GE’s Predix platform also allows it to stream processed data to cloud-based analytics tools, enabling predictive maintenance—for example, detecting abnormal vibration patterns in the turbine rotor that indicate bearing wear, and scheduling maintenance before a failure occurs. This application reduces unplanned downtime by 30–40% and extends the turbine’s service life by 5–7 years.

Related model recommendations

IS200HFPAG2A: GE’s high-frequency pulse acquisition module, which pairs with the IS200DSPXH2C to provide high-resolution speed and position data from turbine encoders. The IS200HFPAG2A captures 2 MHz pulse signals, which the IS200DSPXH2C processes to calculate rotor speed with ±0.05 RPM accuracy.

IS200IVFBG1A: GE’s voltage/frequency feedback module that supplies grid voltage and frequency data to the IS200DSPXH2C. The IS200DSPXH2C uses this data to synchronize the turbine with the grid, ensuring compliance with IEEE 1547 standards.

IS200DTAIH1A: GE’s 16-channel digital input module, which sends status signals (e.g., valve open/close, pump run) to the IS200DSPXH2C. The module’s 1 ms response time complements the IS200DSPXH2C’s fast processing for real-time status monitoring.

IS200EACFG1A: GE’s system configuration and backup module that stores the IS200DSPXH2C’s program and parameters. It enables rapid module replacement—restoring the IS200DSPXH2C’s configuration in 30 seconds or less to minimize downtime.

IC698CPE030: GE’s Mark VIe main controller, which acts as the “brain” of the system and collaborates with the IS200DSPXH2C. The IS200DSPXH2C processes raw sensor data, while the IC698CPE030 executes high-level system control logic.

IS200EHBQG2A: GE’s Mark VIe backplane module that provides power and communication connectivity to the IS200DSPXH2C. It ensures stable data transmission between the IS200DSPXH2C and other Mark VIe components.

IS200JGNDG1A: GE’s system grounding module that enhances the IS200DSPXH2C’s signal integrity. It reduces electrical noise in analog inputs, preventing measurement errors that could impact the IS200DSPXH2C’s control algorithms.

IS200ERIOH1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200DSPXH2C, power off the Mark VIe backplane and verify the ambient temperature is within -40 °C to +85 °C. Use ESD-safe tools (e.g., grounded tweezers, antistatic mat) to prevent electrostatic damage to the module’s components. Confirm the backplane slot is compatible with Mark VIe digital signal processor modules and check the 24 V DC power supply (ensure it meets ±15% tolerance to avoid voltage-related damage). For wiring, use shielded twisted-pair cables (22 AWG for analog inputs, 18 AWG for power) and ground the shield at the sensor end to minimize EMI. Label all connections clearly (e.g., “Exhaust Temp Thermocouple – Channel 1”) to avoid miswiring.

Maintenance suggestions: For daily maintenance, monitor the IS200DSPXH2C’s status via the Mark VIe HMI—check for error codes related to memory, communication, or input channels. Every 3 months, use GE’s ToolboxST software to run a diagnostic test, which validates the module’s processor performance and input/output accuracy. Inspect the module’s physical connections quarterly, re-torquing terminals to 0.3 N·m if loose. If the IS200DSPXH2C fails (e.g., no communication with the controller), first check the Ethernet cable and backplane power before replacing the module. Use only GE-approved spare IS200DSPXH2C modules—third-party alternatives may not meet performance or safety standards, risking turbine control instability.

Service and guarantee commitment

The IS200DSPXH2C comes with a 3-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VIe system operation. If the IS200DSPXH2C fails within this period (e.g., processor malfunction, input channel errors), GE will repair or replace the module free of charge, with expedited shipping from regional warehouses to minimize turbine downtime—a critical benefit for power plants where outages cost $10,000+ per hour.

GE provides 24/7 global technical support for the IS200DSPXH2C, with certified Mark VIe engineers available to assist with installation, troubleshooting, and algorithm optimization via phone, email, or remote access. Customers also gain access to GE’s Digital Industrial Library, which includes the IS200DSPXH2C’s technical manual, programming guides, and application notes. For mission-critical applications (e.g., nuclear power plants), GE offers extended warranty options (up to 5 years) and annual preventive maintenance services, ensuring the IS200DSPXH2C meets IEC 61508 SIL 2 safety requirements and operates at peak performance.