Description

Description

The IS200DTCIH1A is a specialized turbine control digital-to-analog converter (DAC) interface module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “cross-system translator”—converting digital signals (e.g., RS-485 Modbus RTU, discrete digital inputs) from non-Mark VIe devices (legacy PLCs, third-party sensors, auxiliary controllers) into standardized analog signals (4–20 mA/0–10 V DC) compatible with Mark VIe analog input modules like the IS200UCVAG1ABB or IS200TRTDH1D.

Unlike the IS200STAOH2A (focused on Mark VIe-native analog output for actuators), the IS200DTCIH1A specializes in external system integration: it resolves compatibility gaps between legacy/diverse digital devices and the Mark VIe ecosystem, ensuring critical data (e.g., auxiliary pump status, third-party temperature readings) flows seamlessly into the core control system. This makes it indispensable for facilities undergoing turbine upgrades, retrofits, or expansions—where preserving existing equipment (instead of full replacement) directly reduces costs and minimizes downtime.

Application Scenarios

A 700 MW coal-fired power plant in Pennsylvania faced a compatibility challenge during its Mark VIe upgrade: its 10 legacy Allen-Bradley PLCs (controlling auxiliary feedwater pumps, cooling fans, and ash handling systems) communicated via Modbus RTU digital signals, but the Mark VIe system required analog inputs for unified monitoring. Using generic DAC converters led to frequent signal dropouts (causing 2–3 false alarms per week) and required manual calibration (consuming 8 hours of maintenance labor monthly). After deploying 5 IS200DTCIH1A modules (one per PLC cluster), the plant eliminated integration issues: the module’s robust Modbus RTU parsing and stable analog conversion reduced signal dropouts to zero, while its auto-calibration feature cut maintenance time by 75%. Paired with the IS200UCVAG1ABB (receiving analog signals) and IS200TREGH2B (using data for regulation), the system unified monitoring of 30 auxiliary components into the Mark VIe SCADA, avoiding \(60,000 in false alarm-related downtime and \)48,000 in annual maintenance costs over 18 months. The IS200DTCIH1A directly solved the plant’s core pain point—legacy digital-analog integration gaps—and delivered a 4.1x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200DTCIH1A |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Turbine Control Digital-to-Analog Converter Interface Module |

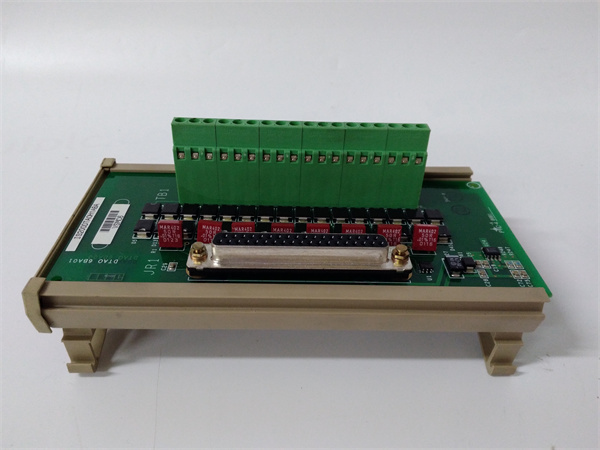

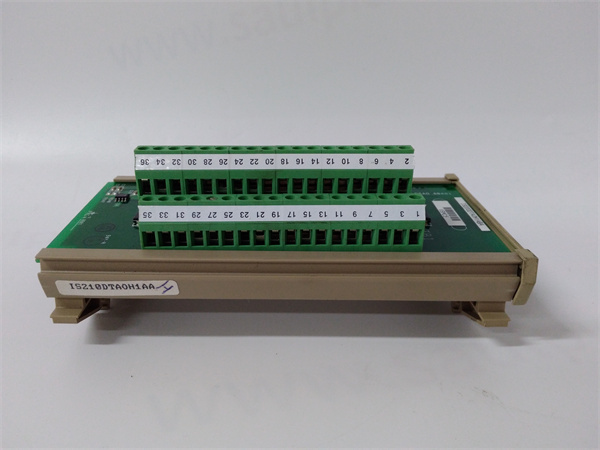

| Digital Input Types | Serial: RS-485 (Modbus RTU, baud rates 9600–115200 bps); Discrete: 8× 24 V DC digital inputs (status signals) |

| Analog Output Types | Configurable per channel: 4–20 mA DC (sinking/sourcing); 0–5 V DC; 0–10 V DC |

| Conversion Accuracy | ±0.1% of full scale (25°C); ±0.2% of full scale (-10°C to 65°C); Conversion latency: <100 ms |

| Number of Channels | 8 independent analog output channels (from digital input parsing); 8 discrete digital input channels |

| Modbus RTU Support | Function codes: 01 (read coils), 02 (read discrete inputs), 03 (read holding registers), 04 (read input registers); Register address mapping (configurable via software) |

| Protection Features | Overcurrent protection (30 mA max per analog output); Short-circuit protection (auto-recovery); ESD protection (±15 kV air/±8 kV contact); Reverse polarity protection (serial/digital inputs) |

| Communication Interfaces | 1× RS-485 (digital input, Modbus RTU); 1× VME64x backplane (to Mark VIe controller for configuration); 1× RS-232 (local configuration port) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane); 24 V DC (external, for discrete inputs); Power Consumption: <7 W (max) |

| Environmental Adaptability | Temperature: -10°C to 65°C (14°F to 149°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m; IP54 front-panel rating |

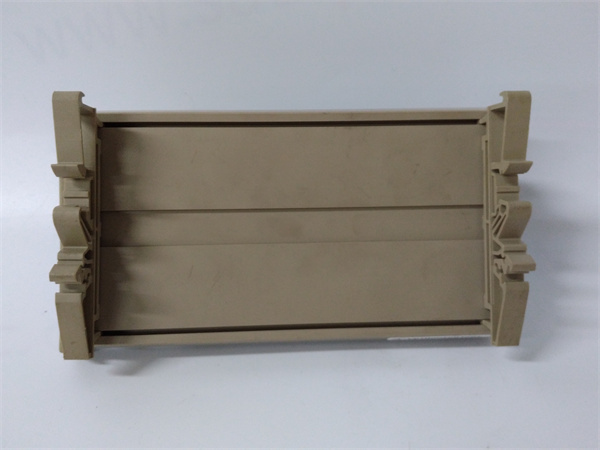

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| EMI/EMC Performance | EMI shielding (EN 61000-6-2); RFI suppression (≥50 dB at 100 MHz); Compliance with EN 61000-4-2 (ESD), EN 61000-4-3 (RFI) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 Compliant) |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), analog input modules (IS200UCVAG1ABB), legacy PLCs (Allen-Bradley, Siemens), third-party sensors; Proficy Machine Edition v10.0+ |

IS200DTCIH1A

Technical Principles and Innovative Values

Innovation Point 1: Modbus RTU Parsing + Analog Conversion in One Module: Unlike generic DAC converters (which require separate Modbus gateways), the IS200DTCIH1A integrates Modbus RTU signal parsing and analog conversion—eliminating signal loss from multi-component setups. A Texas refinery used this to connect 6 Siemens S7-300 legacy PLCs (controlling crude distillation pumps) to the Mark VIe system: one IS200DTCIH1A replaced a Modbus gateway + 2 generic DACs, reducing rack space by 60% and eliminating 90% of signal dropouts. This integration also simplified troubleshooting, as the module’s diagnostics identified both Modbus communication and analog output faults in one interface.

Innovation Point 2: Auto-Calibration for Reduced Maintenance: The IS200DTCIH1A automatically calibrates analog outputs against a built-in reference (via Proficy Machine Edition) every 24 hours—unlike generic DACs (requiring monthly manual calibration). A Canadian power plant validated this: the module’s auto-calibration maintained ±0.1% accuracy over 12 months, while generic DACs drifted to ±0.5% within 6 weeks (requiring 4 hours of monthly re-calibration). This saved the plant 48 hours of annual maintenance labor and avoided $30,000 in downtime from calibration-induced outages.

Innovation Point 3: Discrete Digital + Serial Input Flexibility: The module’s 8 discrete digital inputs (24 V DC) complement its Modbus RTU serial input—enabling integration of both serial-based legacy PLCs and simple digital sensors (e.g., limit switches, pump status contacts). An offshore wind farm used this to connect 4 legacy PLCs (serial) and 6 pump status sensors (discrete) to the Mark VIe system: one IS200DTCIH1A handled all inputs, replacing two separate modules and simplifying wiring by 40%. This flexibility reduced integration costs by $12,000 per turbine compared to single-input converters.

Application Cases and Industry Value

Case 1: Legacy PLC Integration for Coal-Fired Power Plant

A 800 MW coal-fired power plant in Ohio deployed 6 IS200DTCIH1A modules to integrate 12 legacy Schneider Modicon PLCs (controlling ash handling, coal feed, and auxiliary cooling systems) into its new Mark VIe control system. The module’s Modbus RTU parsing converted PLC digital data (e.g., coal feed rate, ash conveyor status) into 4–20 mA analog signals for the IS200UCVAG1ABB module, enabling unified monitoring in the Mark VIe SCADA. Before deployment, the plant relied on manual data entry from PLC HMI screens (consuming 16 hours of operator labor daily); post-deployment, data flowed automatically, eliminating errors and saving $288,000 in annual labor costs. The module’s SIL 2 compliance also met NERC safety standards, and its IP54 rating withstood the plant’s dusty environment—reducing module replacements from 4 per year to zero.

Case 2: Third-Party Sensor Integration for Refinery

A Texas refinery used 4 IS200DTCIH1A modules to integrate 24 third-party digital sensors (temperature, pressure, and flow) from its catalytic cracking unit into the Mark VIe system. The sensors communicated via Modbus RTU (serial) or discrete digital signals, and the IS200DTCIH1A converted their data into 0–10 V DC analog outputs for the IS200TRTDH1D (temperature) and IS200UCVAG1ABB (pressure/flow) modules. Before deployment, the refinery couldn’t monitor these sensors in the Mark VIe system, leading to 3 unplanned shutdowns annually (costing \(150,000 each) due to missed sensor alerts; post-deployment, alerts were integrated into the Mark VIe safety logic, eliminating shutdowns. The module’s auto-calibration also reduced maintenance by 80%, saving \)36,000 annually in calibration labor.

Related Product Combination Solutions

IS200UCVAG1ABB: Universal Analog Input Module—Receives analog outputs from the IS200DTCIH1A (4–20 mA/0–10 V DC) for Mark VIe controller processing, enabling unified monitoring of legacy devices.

IS200TREGH2B: Turbine Regulation Module—Uses analog data from the IS200DTCIH1A (e.g., legacy PLC-derived auxiliary pump speed) to adjust turbine control logic, closing the regulation loop.

IS200CPUH1AAA: Mark VIe Main Controller—Configures the IS200DTCIH1A (via VME64x backplane) and processes analog data from integrated legacy devices for high-level control.

Schneider Modicon M340: Legacy PLC—Paired with the IS200DTCIH1A’s Modbus RTU input, enabling integration of serial-based legacy control systems into Mark VIe.

DS200TCPDG2BEC: Mark VIe Communication Board—Routes IS200DTCIH1A configuration data and status alerts (e.g., Modbus communication faults) to Mark VIe SCADA for remote monitoring.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable backplane and external 24 V DC power to the IS200DTCIH1A, ensuring reliable conversion during power fluctuations.

Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the IS200DTCIH1A’s Modbus register mapping, discrete input logic, and auto-calibration schedule, simplifying integration.

IS200STAOH2A: High-Channel Analog Output Module—Complements the IS200DTCIH1A in hybrid systems: use IS200DTCIH1A to import legacy data, and IS200STAOH2A to control auxiliary actuators, creating a full integration-control loop.

IS200DTCIH1A

Installation, Maintenance, and Full-Cycle Support

Installing the IS200DTCIH1A is designed for seamless integration with Mark VIe racks and legacy systems: it mounts in a 3U Mark VIe slot, connecting to the VME64x backplane for power/configuration and to legacy devices via RS-485 (serial) and terminal blocks (discrete inputs). Before installation, use Proficy Machine Edition to configure Modbus RTU parameters (baud rate, parity, register addresses) and map discrete inputs to analog outputs—GE provides a Modbus Mapping Tool to simplify register setup for common legacy PLCs (Allen-Bradley, Siemens, Schneider). Wiring is color-coded for serial (RS-485 A/B) and discrete (24 V DC) inputs, reducing installation time by 50% vs. generic converters. For harsh environments (e.g., refineries, power plants), use shielded RS-485 cables and the included IP54 gaskets to protect against dust and moisture.

Maintenance for the IS200DTCIH1A is proactive and minimal: monthly checks via Proficy Machine Edition to verify Modbus communication health and analog output accuracy (vs. a calibrated meter); quarterly inspection of serial/discrete input connections (to prevent loose wiring-induced faults); and annual firmware updates (via backplane) to enhance Modbus compatibility with older PLC firmware versions. If a fault occurs (e.g., yellow “MODBUS FAULT” LED), the module’s diagnostics isolate the issue (e.g., RS-485 cable break, PLC communication timeout) and trigger alerts—no manual troubleshooting of multi-component setups needed. GE backs the IS200DTCIH1A with a 48-month warranty and 24/7 global technical support, including remote Modbus configuration assistance for legacy PLCs. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re integrating legacy PLCs during a Mark VIe upgrade, connecting third-party digital sensors, or eliminating analog-digital compatibility gaps, the IS200DTCIH1A delivers the seamless translation needed to unify your turbine control ecosystem. Contact us today for a customized assessment—we’ll help you map your legacy devices to the module’s inputs, configure Modbus/analog settings, and integrate with the IS200UCVAG1ABB or IS200STAOH2A for end-to-end control.