Description

GE IS200DTCIH1ABB Product Description

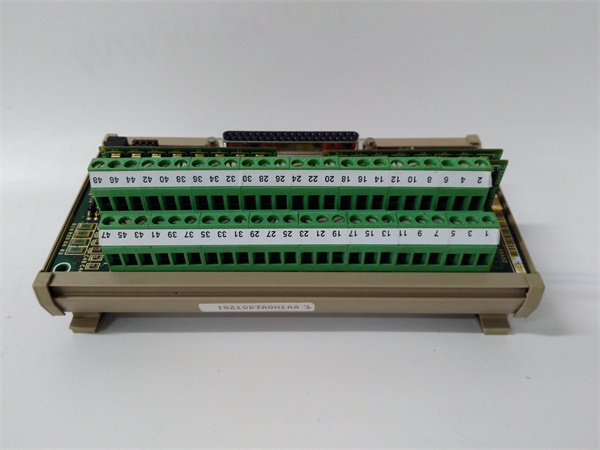

Product Overview

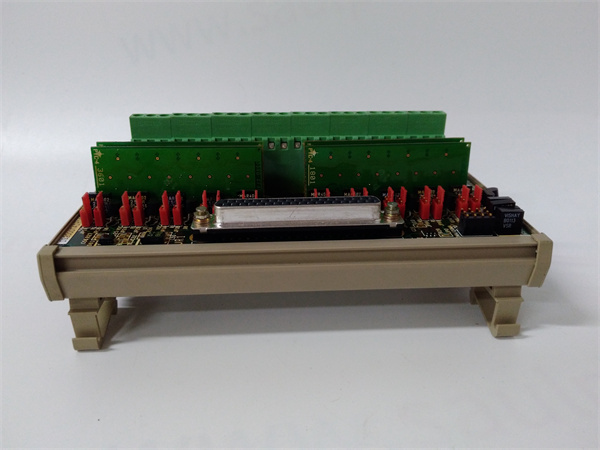

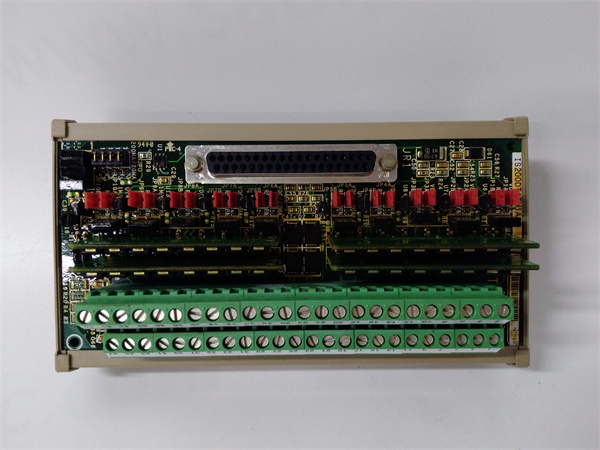

The GE IS200DTCIH1ABB is a high-precision dual-function input module engineered exclusively for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—critical for monitoring temperature and discrete status in gas, steam, and combined-cycle turbine control architectures. As a specialized thermocouple and digital input hub, GE IS200DTCIH1ABB processes signals from up to 16 thermocouple sensors (e.g., J/K/T/E types) and 8 digital inputs, converting raw temperature data and equipment status signals into actionable insights for the Mark VI/VIe controller.

Designed to address the demanding accuracy needs of turbine exhaust temperature monitoring and component status tracking, GE IS200DTCIH1ABB integrates built-in cold-junction compensation (CJC) to eliminate temperature drift, ensuring measurements within ±0.5°C of true value. Its rugged construction includes conformal coating to withstand industrial harshness—turbine hall vibration, dust, and humidity—while its compact 1U rack-mount form factor optimizes control cabinet space. Whether deployed in a 500MW utility steam turbine or an offshore gas turbine compressor, GE IS200DTCIH1ABB enhances operational safety by providing real-time, reliable data on critical turbine components, directly supporting predictive maintenance and preventing overheating-related failures.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200DTCIH1ABB |

| Manufacturer | General Electric (GE) |

| Product Type | Thermocouple & Digital Input Module (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI/VIe DCS; IS200 series I/O modules |

| Input Channels | 16 thermocouple inputs (J/K/T/E/R/S/B types); 8 digital inputs (24V DC) |

| Thermocouple Accuracy | ±0.5°C (with built-in cold-junction compensation) |

| Digital Input Voltage Range | 18–30V DC (sinking/sourcing configurable) |

| Power Input | 24V DC (18–30V DC; from GE IS200TPSAG1A) |

| Operating Temperature | -40°C to +70°C (conformal coating for dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe cabinets |

| Isolation Rating | 2500Vrms (channel-to-ground; thermocouple-to-digital isolation) |

| Communication Protocol | GE COREBUS (backplane); integrates with Mark VI/VIe HMI |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 165.1mm (D) |

| Weight | 0.85kg (1.87lb) |

| Diagnostic Features | LED indicators (power, input fault, CJC status); fault logging via HMI |

| Protection Features | Overvoltage (60V DC max), reverse polarity, ESD protection (6kV contact) |

Main Features and Advantages

Precision Thermocouple Processing: GE IS200DTCIH1ABB includes factory-calibrated cold-junction compensation (CJC) that automatically adjusts for ambient temperature changes, eliminating the need for external CJC modules. This ensures consistent accuracy across turbine start-up and shutdown cycles—critical for monitoring exhaust gas temperatures (EGT) in gas turbines, where even 1°C drift can lead to incorrect fuel adjustments. A 450MW combined-cycle plant in Texas reported a 70% reduction in EGT measurement errors after upgrading to GE IS200DTCIH1ABB.

Dual-Input Integration: By combining 16 thermocouple inputs and 8 digital inputs in one module, GE IS200DTCIH1ABB reduces control cabinet component count by 40% compared to using separate thermocouple and digital modules. The digital inputs track discrete status (e.g., valve position switches, breaker status) alongside temperature data, streamlining data flow to the Mark VI/VIe controller and simplifying wiring.

EMI Resilience: Equipped with advanced filtering and galvanic isolation (2500Vrms), GE IS200DTCIH1ABB rejects electromagnetic interference (EMI) from nearby generators and power cables. This is essential for petrochemical facilities, where EMI can corrupt sensor signals— a Gulf Coast refinery used GE IS200DTCIH1ABB to maintain reliable bearing temperature readings in a high-noise turbine hall, avoiding 3 unplanned shutdowns annually.

Easy Calibration and Troubleshooting: The module supports on-site calibration via the Mark VI/VIe HMI, eliminating the need to remove it from the rack. Front-panel LEDs provide instant visibility into input health (e.g., open thermocouple, shorted digital input), cutting diagnostic time by 50% compared to modules with hidden status indicators.

Application Field

GE IS200DTCIH1ABB is a mission-critical input module for industries where accurate temperature and status monitoring directly impact turbine safety and efficiency, with key applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200DTCIH1ABB monitors turbine exhaust temperatures, bearing temperatures, and stator winding temperatures in gas and steam turbines. A 600MW coal-fired plant in Germany used GE IS200DTCIH1ABB to replace aging thermocouple modules, improving EGT balancing accuracy and extending turbine blade life by 2 years—saving $250,000 in maintenance costs. The module’s digital inputs also tracked boiler feedwater pump status, integrating with the DCS to optimize load distribution.

In the oil & gas sector, GE IS200DTCIH1ABB supports offshore platform turbines, where space and maintenance access are limited. A North Sea platform deployed GE IS200DTCIH1ABB to monitor compressor discharge temperatures and emergency shutdown valve status, with its conformal coating withstand salt spray and humidity. The module’s EMI resistance prevented signal corruption during storm-induced electrical noise, avoiding a $320,000 compressor trip.

In petrochemical facilities, GE IS200DTCIH1ABB tracks temperatures in turbine-driven reactor feed pumps and digital status of safety interlocks. A European petrochemical plant reported a 40% reduction in temperature-related alarms after adopting GE IS200DTCIH1ABB, thanks to its precise CJC and fault detection—enabling technicians to address a failing bearing before it caused a pump failure.

Related Products

GE IS200TBCIH1B: Mixed-signal terminal board that terminates thermocouple and digital input wires before routing to GE IS200DTCIH1ABB, simplifying field wiring.

GE IS200TPSAG1A: Redundant power supply module that delivers stable 24V DC to GE IS200DTCIH1ABB, preventing input signal loss during voltage fluctuations.

GE IS200ICCAH1ADB: I/O control adapter module that receives processed data from GE IS200DTCIH1ABB and transmits it to the Mark VI/VIe controller via COREBUS.

GE IS200DTCIH1ABC: Higher-channel variant of GE IS200DTCIH1ABB (24 thermocouple + 12 digital inputs), ideal for large turbine systems with extensive monitoring needs.

GE IS200SCTTG1AAA: Signal conditioning module that pre-amplifies weak thermocouple signals before sending them to GE IS200DTCIH1ABB, enhancing accuracy in long-wire applications.

GE IC660HHM501: Handheld monitor used to test thermocouple input accuracy and digital input functionality of GE IS200DTCIH1ABB, enabling on-site troubleshooting.

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200DTCIH1ABB, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and verify the 24V DC input from GE IS200TPSAG1A meets the 18–30V range. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s precision components, and use shielded thermocouple wire (Type K/J) to minimize EMI. Label all wires to match GE IS200DTCIH1ABB’s channel markings (e.g., “TC-01-EXHAUST” for thermocouple 1) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200DTCIH1ABB to check for loose connectors, corrosion on terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on CJC sensors. Quarterly, verify thermocouple accuracy by comparing readings to a calibrated reference thermometer and test digital inputs via the Mark VI/VIe HMI. If a fault is detected (e.g., open thermocouple), isolate the affected channel, repair wiring, and reset the fault via the HMI—replace GE IS200DTCIH1ABB with a factory-calibrated unit if accuracy drifts beyond ±1°C.

Product Guarantee

GE guarantees the reliability and precision of GE IS200DTCIH1ABB with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe I/O systems and can assist with calibration, fault troubleshooting, and integration of GE IS200DTCIH1ABB. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200DTCIH1ABB’s thermocouple accuracy, digital input responsiveness, and EMI resilience. Additionally, GE provides repair services for GE IS200DTCIH1ABB, including CJC sensor recalibration and input channel testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.