Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

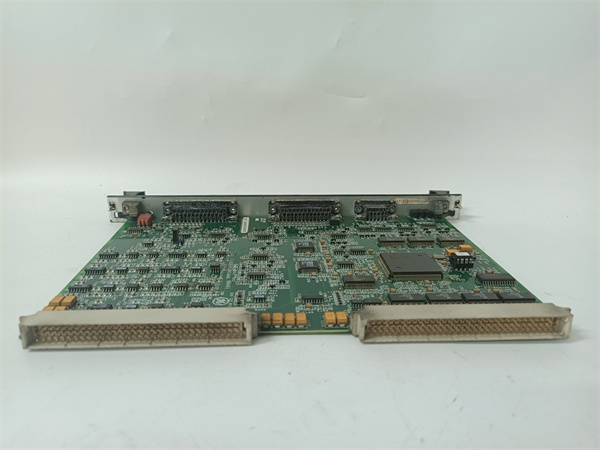

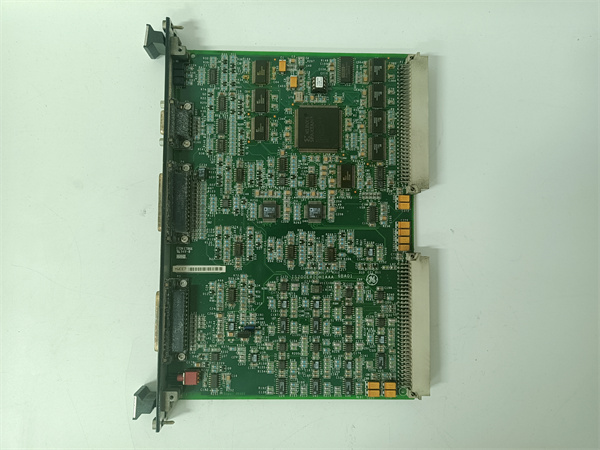

| Product model | IS200DTTCH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Digital I/O Transition Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| I/O channel configuration | 8 digital input channels + 8 digital output channels (configurable per channel) |

| Input signal types | Dry contact (NO/NC); 12 V DC / 24 V DC sinking/sourcing (legacy sensor compatibility) |

| Output signal types | 24 V DC sinking/sourcing (Mark VI backplane-compatible); relay contact (SPDT, 5 A @ 240 V AC) |

| Signal conversion range | 12 V DC input → 24 V DC output (level shifting); dry contact → voltage signal (wetting) |

| Input voltage range | 10 V DC to 32 V DC (for voltage inputs); dry contact (0 V, open/closed) |

| Output current capacity | 2 A per output channel (voltage); 5 A per output channel (relay) |

| Response time | Input: ≤ 1 ms (typical); Output: ≤ 2 ms (typical) |

| Isolation | Channel-to-channel: 2.5 kV rms; Input/output-to-backplane: 5 kV rms |

| Protection features | Overcurrent protection (per output channel, 2.5 A fuse); ESD protection (15 kV contact/8 kV air); reverse polarity protection |

| Status indicators | 16 LED indicators (1 per channel: green = active, red = fault); 1 power LED (green); 1 backplane communication LED (amber) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Storage temperature range | -55 °C to +125 °C (-67 °F to 257 °F) |

| Physical dimensions | 35 mm (W) × 30 mm (H) × 12 mm (D) (1.38 in × 1.18 in × 0.47 in) |

| Weight | 450 g (0.99 lb) |

| Interface type | 32 terminal connections (t1-t32: 2 per channel for input/output); 1 edge-mounted Mark VI backplane connector (p1); 1 auxiliary power connector (p2, 24 V DC) |

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes; compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1; UL 508 (relay outputs) |

| MTBF (Mean Time Between Failures) | 2,100,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

IS200ERIOH1A

Product Introduction

The IS200DTTCH1A is a dedicated digital I/O transition module engineered by GE for its Mark VI Speedtronic turbine control system—the industry standard for retrofitting and upgrading aging turbine fleets. As a “compatibility bridge,” the IS200DTTCH1A solves a critical challenge in turbine modernization: legacy digital sensors/actuators (e.g., 12 V DC proximity switches, mechanical relays) often use signal levels or interfaces incompatible with the Mark VI backplane’s native 24 V DC I/O.

Unlike generic signal converters that require external wiring and lack Mark VI integration, the IS200DTTCH1A combines 8 input channels (for legacy sensor signals) and 8 output channels (for Mark VI-compatible control signals) in a single module. It performs real-time signal conversion—such as shifting 12 V DC sensor inputs to 24 V DC for the Mark VI controller, or translating Mark VI digital outputs to relay contacts for old actuators—while maintaining 2.5 kV isolation to prevent ground loops. In GE’s Mark VI ecosystem, the IS200DTTCH1A is indispensable for plants upgrading from pre-Mark VI systems (e.g., Mark V) or integrating third-party digital devices, avoiding costly replacement of functional legacy equipment.

Core Advantages and Technical Highlights

Dual-Function I/O (8 Inputs + 8 Outputs) for Retrofit Flexibility: The IS200DTTCH1A’s combined input/output design eliminates the need for separate conversion modules for legacy sensors and actuators. For example, in a plant upgrading a Mark V turbine to Mark VI, the module can accept 8 legacy 12 V DC limit switch inputs (from fuel valves) and provide 8 24 V DC relay outputs (to control old lube oil pumps)—all via one IS200DTTCH1A. This reduces backplane space by 40% compared to using two single-function modules and cuts retrofit wiring time by 30%.

Multi-Signal Conversion for Legacy Compatibility: The IS200DTTCH1A supports three key conversion types critical for retrofits: 1) Dry contact → 24 V DC (wetting legacy mechanical switches for Mark VI detection); 2) 12 V DC → 24 V DC (level-shifting old proximity sensors); 3) Mark VI 24 V DC → relay contact (controlling legacy actuators that lack voltage inputs). Generic converters typically handle only one conversion type, but the IS200DTTCH1A’s configurable channels adapt to mixed legacy devices—saving plants $10,000+ in unnecessary sensor/actuator replacements per turbine.

Built-In Protection for Legacy Device Safety: Legacy equipment is often more sensitive to voltage spikes or reverse polarity than modern Mark VI components. The IS200DTTCH1A addresses this with per-output overcurrent fuses (2.5 A), reverse polarity protection (for input wiring errors), and 15 kV ESD protection. For example, if a technician accidentally wires a 24 V DC Mark VI output to a 12 V DC legacy actuator, the module’s reverse polarity protection prevents damage to the actuator—avoiding $2,000+ in repair costs and unplanned downtime.

Seamless Mark VI Integration (No Custom Programming): Unlike third-party converters that require custom drivers or HMI configuration, the IS200DTTCH1A is natively recognized by the Mark VI controller. Engineers configure input/output types (e.g., dry contact vs. 12 V DC) directly via GE’s Mark VI Toolbox software—same tool used for other IS200-series modules. This eliminates training on new software and ensures the module’s status (e.g., input faults, output overloads) is visible in the Mark VI HMI, enabling centralized troubleshooting.

Typical Application Scenarios

In a coal-fired power plant upgrading a GE Mark V turbine to Mark VI, the IS200DTTCH1A serves as the retrofit’s digital I/O backbone. It connects to 8 legacy 12 V DC proximity sensors (monitoring turbine rotor position) and converts their signals to 24 V DC for the Mark VI controller. On the output side, the module translates Mark VI digital commands into relay contacts to control 6 old lube oil pumps (which lack voltage inputs) and 2 mechanical brake actuators. The IS200DTTCH1A’s isolation prevents ground loops between the Mark VI’s 24 V DC system and the turbine’s legacy 12 V DC wiring, ensuring no false signals disrupt startup sequencing. By reusing 14 legacy devices, the plant avoids $70,000+ in replacement costs.

In a petrochemical plant integrating third-party digital flame detectors (12 V DC) into a Mark VI-controlled gas turbine, the IS200DTTCH1A acts as the interface. Its 8 input channels accept the detectors’ 12 V DC fault signals, converting them to 24 V DC for the Mark VI controller—enabling the controller to trigger emergency shutdowns if a flame is lost. The module’s 8 output channels provide Mark VI-compatible 24 V DC signals to third-party alarm horns (for local alerts). The IS200DTTCH1A’s EMC immunity ensures detector signals remain stable near the turbine’s 480 V AC generator, avoiding false alarms that could shut down production.

Related Model Recommendations

IS200DTAIH1A: GE’s 16-channel digital input module that complements the IS200DTTCH1A. For plants with more legacy inputs than the IS200DTTCH1A’s 8 channels, the IS200DTAIH1A handles additional 24 V DC inputs, while the IS200DTTCH1A manages legacy 12 V DC/dry contact signals.

IS200DTAOH1A: GE’s 16-channel digital output module that pairs with the IS200DTTCH1A. If the IS200DTTCH1A’s 8 relay/voltage outputs are insufficient, the IS200DTAOH1A adds 16 more 24 V DC outputs for modern actuators.

IS200HFPAG1A: GE’s high-frequency power supply module that powers the IS200DTTCH1A (via 24 V DC auxiliary power). Its stable output ensures the module’s conversion circuits operate reliably during grid fluctuations.

IS200JGNDG1A: GE’s system grounding module that enhances the IS200DTTCH1A’s performance. Its low-impedance grounding eliminates noise in legacy sensor signals, preventing conversion errors.

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine system, which relies on the IS200DTTCH1A’s converted signals for legacy device monitoring and control.

IS200DTTCH0A: GE’s 4-input/4-output variant of the IS200DTTCH1A, ideal for small retrofits (e.g., upgrading a single turbine auxiliary system) where fewer channels are needed.

GE Mark V to Mark VI Retrofit Kit: A GE-approved kit that includes the IS200DTTCH1A as a key component, providing pre-configured wiring diagrams and software settings for seamless Mark V-to-Mark VI upgrades.

IS200SCSFG1A: GE’s system synchronization module that aligns the IS200DTTCH1A’s signal timing with the Mark VI controller. This ensures converted legacy input data is time-aligned with other Mark VI I/O (e.g., analog temperature signals) for accurate fault analysis.

IS200ERIOH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200DTTCH1A, power off the Mark VI backplane and legacy equipment to prevent signal conflicts. Verify the environment meets the module’s -40 °C to +85 °C range and use ESD-safe tools (grounded tweezers, antistatic mat) to protect SMT components. Confirm the backplane slot is compatible with IS200-series transition modules and connect the 24 V DC auxiliary power (from IS200HFPAG1A) to connector p2. For legacy wiring: use 22 AWG shielded cable for 12 V DC inputs (ground shield at the sensor end) and 18 AWG wire for relay outputs (to handle 5 A current). Label channels clearly (e.g., “Legacy 12 V DC Switch Input 1”) to avoid misconfiguration.

Maintenance suggestions: For daily maintenance of the IS200DTTCH1A, check the 16 channel LEDs, power LED, and communication LED during shift handovers—red LEDs indicate channel faults (e.g., overcurrent), while a dark communication LED signals backplane connection issues. Every 3 months, inspect terminal connections for tightness (re-torque to 0.3 N·m) and test overcurrent fuses (replace with GE-approved 2.5 A fuses if blown). Annually, use a signal generator to verify conversion accuracy (e.g., 12 V DC input → 24 V DC output ±2%). If a channel fails, first test the legacy device and wiring with a multimeter—faulty sensors often cause conversion errors. Use only GE-approved spare IS200DTTCH1A modules—third-party alternatives lack Mark VI compatibility and may damage legacy equipment.

Service and Guarantee Commitment

The IS200DTTCH1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI operation. If the module fails within this period (e.g., conversion inaccuracy, relay failure), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize retrofit downtime—critical for plants relying on legacy equipment during modernization.

GE offers 24/7 global technical support for the IS200DTTCH1A: certified Mark VI engineers specialize in retrofit applications and assist with channel configuration, signal conversion testing, and legacy device integration via phone, email, or remote access. Customers gain access to GE’s Digital Industrial Library, which includes the IS200DTTCH1A’s technical manual, retrofit wiring guides, and application notes (e.g., “Integrating Mark V Sensors into Mark VI Systems”).

For large-scale retrofits (e.g., multi-turbine fleets) or mission-critical applications (e.g., nuclear power plant auxiliaries), GE provides extended warranty options (up to 5 years) and dedicated retrofit support—trained technicians perform on-site installation verification, conversion testing, and operator training to ensure the IS200DTTCH1A meets project timelines and safety standards. This commitment reflects GE’s confidence in the module’s reliability and dedication to making turbine modernization cost-effective and seamless.