Description

Product Overview

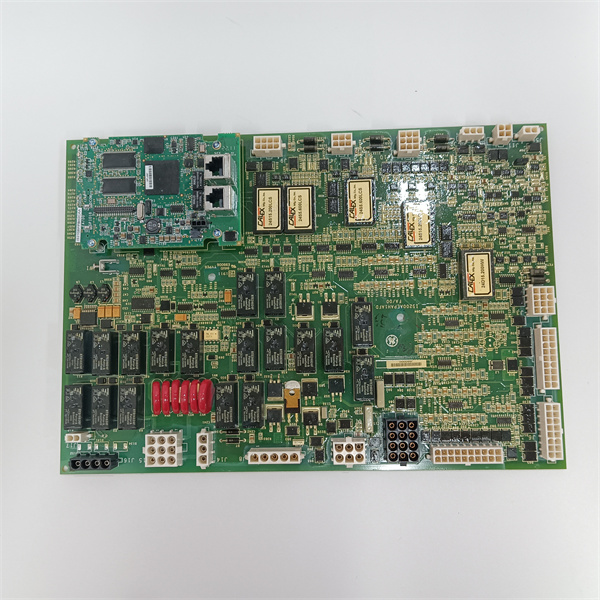

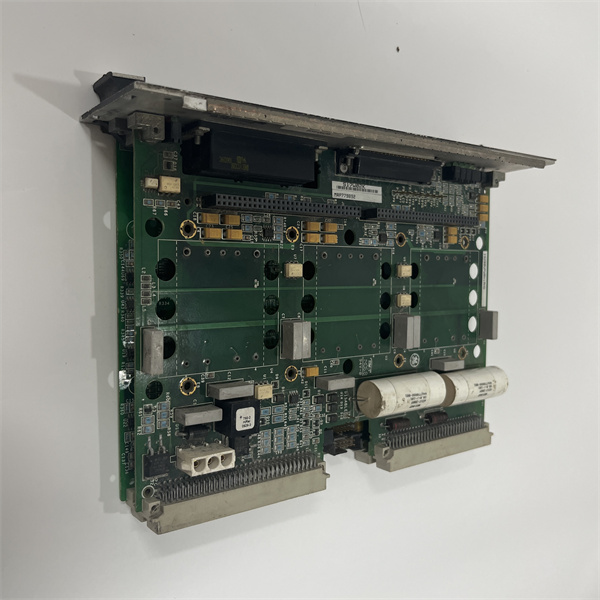

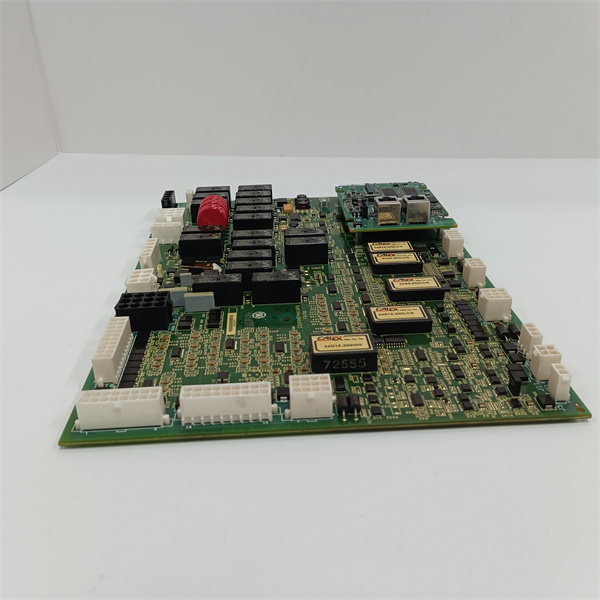

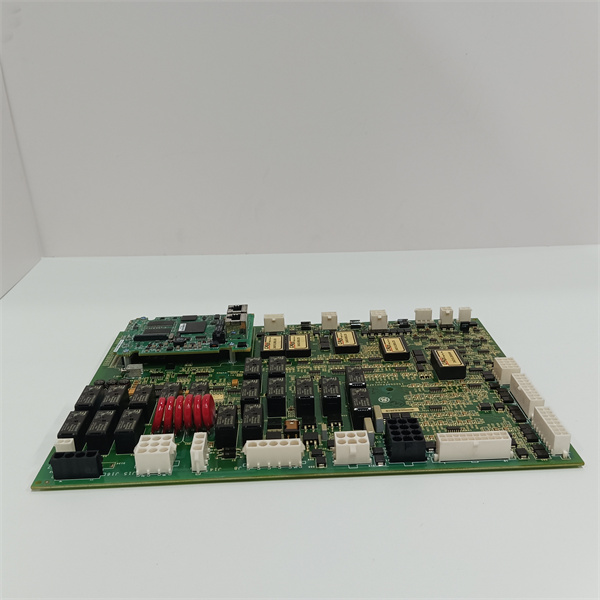

The GE IS200ECTBG1ADE is a printed circuit board meticulously crafted by General Electric for its esteemed Mark VI series within the Speedtronic family. This board serves as a crucial excitation contact terminal card, playing a pivotal role in the control mechanisms of industrial systems, particularly those involving steam and gas operations.

Engineered with precision, the GE IS200ECTBG1ADE is designed to function within redundant systems. It provides a reliable interface for managing excitation processes, ensuring seamless communication and control within the overall industrial setup. As part of the Speedtronic series, known for its robustness and adaptability in harsh industrial environments, this board contributes to the efficient operation of various industrial applications, from power generation plants to manufacturing facilities.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IS200ECTBG1ADE

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Excitation Contact Terminal Board

|

|

Series

|

Mark VI Speedtronic

|

|

System Mode

|

Redundant

|

|

Auxiliary Contact Inputs

|

6

|

|

Power Supply Voltage

|

70 Vdc

|

|

Number of General – Purpose Relay Outputs

|

4 (Form – C)

|

|

Trip Contact Outputs

|

2

|

|

Terminal Strips

|

2 (located along one edge)

|

|

Three – Position Plugs

|

2 (on the board surface)

|

|

D – shell Connectors

|

3 (for cable connection along one long edge)

|

|

Physical Dimensions

|

11 x 6 x 6.7 cm

|

|

Weight

|

0.14 kg

|

IS200AEPAH1AFD

Main Features and Advantages

Redundancy for Enhanced Reliability

The GE IS200ECTBG1ADE is specifically designed for redundant systems. This redundancy feature ensures continuous operation even in the event of a component failure. In critical industrial applications where downtime can lead to significant losses, the board’s ability to maintain functionality through redundancy provides an added layer of reliability. For example, in power plants, the seamless operation of the steam and gas control systems, enabled by the redundant design of the GE IS200ECTBG1ADE, helps prevent disruptions in power generation.

Precise Control with Multiple Inputs and Outputs

Equipped with six auxiliary contact inputs powered by the M1/M2 power supplies, the board allows for versatile and accurate control over excitation processes. These inputs can receive signals from various sensors and control devices, providing real – time data for precise decision – making. Additionally, the four general – purpose (Form – C) relay outputs, controlled by the nearby connected EMIO board, offer flexible control options. The two trip contact outputs, which drive a customer lockout, further enhance the safety and control aspects of the system. This combination of inputs and outputs enables the GE IS200ECTBG1ADE to precisely manage the excitation processes in industrial systems.

Durable Construction for Harsh Environments

As part of GE’s Speedtronic series, the GE IS200ECTBG1ADE is built to withstand the rigors of industrial use. Constructed from high – quality materials, it can endure extreme temperatures, vibrations, and electrical noise commonly found in industrial settings. In manufacturing plants or oil and gas refineries, where the operating environment is harsh, the board’s durable construction ensures long – term reliability and operational uptime, reducing the need for frequent replacements and maintenance.

IS200AEPAH1AFD

Application Field

In power generation plants, the GE IS200ECTBG1ADE is extensively used in the control systems of steam and gas turbines. It plays a vital role in regulating the excitation of the turbines, which in turn affects their speed and power output. By accurately managing the excitation processes, the board helps optimize the performance of the turbines, leading to efficient power generation.

Industrial manufacturing facilities also benefit from the GE IS200ECTBG1ADE. In processes that involve large – scale motors and generators, the board is used to control the excitation systems. For instance, in a steel mill, where powerful motors are used for various operations, the GE IS200ECTBG1ADE ensures the smooth operation of these motors by precisely controlling their excitation, contributing to the overall productivity of the manufacturing process.

The oil and gas industry relies on the GE IS200ECTBG1ADE for its critical control functions. In gas compression stations or oil refineries, the board is used in the control systems that manage the operation of compressors and pumps. Its ability to function reliably in harsh environments, combined with its precise control capabilities, makes it an ideal choice for ensuring the safe and efficient operation of equipment in the oil and gas sector.

Related Products

GE IS200ECTBG2: This is the counterpart of the GE IS200ECTBG1ADE for simplex systems. While the GE IS200ECTBG1ADE is designed for redundant systems, the IS200ECTBG2 is tailored for single – channel setups, providing a different configuration option for industrial applications with less complex redundancy requirements.

GE Mark VI Control Systems: The GE IS200ECTBG1ADE is an integral part of the Mark VI control systems. These systems are responsible for the overall management of industrial processes, such as turbine control. The board interfaces with other components within the Mark VI system, such as the EMIO board, to ensure seamless operation and control.

GE Power Supplies (M1/M2): The GE IS200ECTBG1ADE relies on the M1/M2 power supplies to power its six auxiliary contact inputs. These power supplies are designed to provide a stable 70 Vdc, ensuring the proper functioning of the board’s input mechanisms.

GE EMIO Boards: The four general – purpose (Form – C) relay outputs of the GE IS200ECTBG1ADE are controlled by the nearby connected EMIO boards. The EMIO boards play a crucial role in sending control signals to the GE IS200ECTBG1ADE, enabling it to perform its control functions accurately.

GE Industrial Sensors: The six auxiliary contact inputs of the GE IS200ECTBG1ADE can receive signals from various industrial sensors. These sensors can detect parameters such as temperature, pressure, and vibration, providing real – time data that the board uses to make control decisions in industrial processes.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200ECTBG1ADE, carefully read the installation manual provided by General Electric. Ensure that the installation environment meets the specified temperature and humidity requirements. Check the compatibility of the board with other components in the redundant system, especially the power supplies (M1/M2) and the EMIO board. Power down all related equipment to avoid the risk of electrical shock and damage to components. Verify that the terminal strips, three – position plugs, and D – shell connectors on the board are in good condition. Make sure the installation area is clean and free from dust and debris, as these can affect the performance of the board.

Maintenance recommendations: Regularly inspect the GE IS200ECTBG1ADE for any signs of physical damage, such as cracks on the circuit board or loose connections. Check the functionality of the board by monitoring the input and output signals. Clean the board periodically using a soft, dry brush to remove dust and dirt, as these can accumulate over time and cause electrical problems. In case of any malfunction, refer to the troubleshooting section of the manual. If the issue persists, contact GE’s technical support or a qualified technician for further assistance. Keep the board’s firmware updated to the latest version provided by GE, as firmware updates often include bug fixes, performance improvements, and enhanced compatibility.

Product Guarantee

General Electric stands firmly behind the quality of the GE IS200ECTBG1ADE. The board is manufactured using high – quality materials and advanced manufacturing processes, ensuring that it meets strict quality standards. GE offers a standard warranty period for the product, during which any manufacturing defects will be rectified free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. Whether it’s answering questions about the board’s operation or providing guidance on maintenance, customers can rely on GE’s expertise. This guarantee reflects GE’s confidence in the product and their commitment to providing reliable industrial control solutions, giving customers peace of mind when using the GE IS200ECTBG1ADE in their critical applications.