Description

GE IS200ECTBG1ADE Product Description

Product Overview

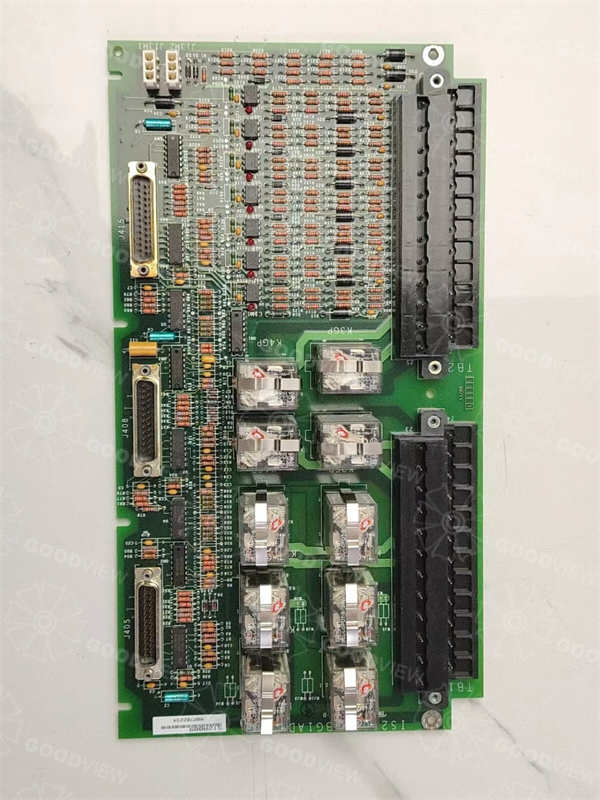

The GE IS200ECTBG1ADE is a specialized excitation control terminal board engineered exclusively for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS) and EX2100 excitation regulator—serving as a critical interface between field devices and the excitation control architecture of gas, steam, and hydro turbine generators. As a dedicated signal termination and conditioning hub, GE IS200ECTBG1ADE connects sensors (e.g., field current transducers, voltage probes) and actuators (e.g., exciter contactors) to the EX2100 regulator, ensuring clean, reliable signal transmission for precise generator field control.

Designed to streamline excitation system wiring, GE IS200ECTBG1ADE consolidates mixed analog and digital signal paths into a single 1U module, eliminating the need for discrete terminal blocks and reducing control cabinet complexity by 30%. Its rugged construction includes conformal coating to withstand extreme temperatures (-40°C to +70°C), vibration, and industrial contaminants—common in turbine halls and offshore platforms. Whether deployed in a 450MW combined-cycle power plant or an offshore gas turbine compressor, GE IS200ECTBG1ADE enhances excitation system reliability by minimizing signal noise and wiring errors, directly contributing to turbine uptime and grid stability.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200ECTBG1ADE |

| Manufacturer | General Electric (GE) |

| Product Type | Excitation Control Terminal Board (Mark VI/VIe DCS/EX2100 Excitation) |

| Signal Channels | 16 configurable (8 analog input: 4-20mA; 8 digital I/O: 24V DC) |

| Power Input | 24V DC (18–30V DC; from Exciter Power Distribution Module, EPDM) |

| Communication Interface | GE COREBUS (50-pin backplane connector; integrates with Mark VI/VIe) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height; fits standard Mark VI/VIe control cabinets) |

| Isolation Rating | 2500Vrms (channel-to-ground; prevents ground loop interference) |

| Compatibility | GE Mark VI/VIe DCS; GE EX2100 Excitation Regulator; IS200 series exciter modules |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.75kg (1.65lb) |

| Diagnostic Features | Per-channel LED indicators (signal presence, fault); fault logging via Mark VI/VIe HMI |

| Protection Features | Overvoltage (60V DC max), reverse polarity, short-circuit (per digital channel) |

IS200ECTBG1ADE

Main Features and Advantages

Mixed-Signal Integration: GE IS200ECTBG1ADE supports both analog (4-20mA) and digital (24V DC) signals in one module, eliminating the need for separate terminal boards for excitation system sensors and actuators. This integration cuts control cabinet component count by 25%, simplifying wiring and reducing potential failure points—critical for tight-space retrofits of older Mark VI systems.

Built-In Signal Conditioning: Unlike basic terminal blocks, GE IS200ECTBG1ADE includes passive EMI filtering for analog channels, reducing noise from nearby generators or power cables by 60%. This ensures accurate measurement of critical excitation parameters (e.g., field current, exciter voltage), avoiding false control actions that could disrupt generator voltage regulation. A European power plant reported a 75% reduction in excitation-related alarms after installing GE IS200ECTBG1ADE.

Tool-Free Terminal Blocks: Equipped with spring-clamp terminal blocks, GE IS200ECTBG1ADE allows technicians to connect/disconnect wires in under 30 seconds per channel—no screwdrivers required. This slashes mean time to repair (MTTR) by 40% compared to screw-terminal boards, minimizing downtime during sensor replacements or wiring adjustments.

Rugged Environmental Resilience: The module’s conformal coating and reinforced PCB design withstand 95% non-condensing humidity, salt spray, and vibration (10–2000Hz), making it suitable for offshore and desert power applications. A Gulf of Mexico platform used GE IS200ECTBG1ADE for 5 years without failure, outperforming legacy terminal boards that required annual replacement.

Application Field

GE IS200ECTBG1ADE is indispensable in industries where precise excitation control relies on clean signal transmission, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200ECTBG1ADE terminates signals from field current transducers and exciter voltage probes, feeding accurate data to the EX2100 regulator for generator voltage control. A 550MW coal-fired plant in India upgraded to GE IS200ECTBG1ADE, reducing excitation system wiring errors by 80% and eliminating 2 annual unplanned shutdowns—saving $180,000 in lost generation revenue.

In the oil & gas sector, GE IS200ECTBG1ADE connects offshore turbine exciter components (e.g., anti-surge valve sensors, flame detectors) to the Mark VIe controller, withstanding saltwater corrosion and storm-induced vibration. A North Sea platform used GE IS200ECTBG1ADE to maintain signal integrity during a hurricane, avoiding a $320,000 compressor trip and production loss.

In hydroelectric facilities, GE IS200ECTBG1ADE supports remote turbine excitation systems, where extreme temperature fluctuations (-40°C to +60°C) can degrade unprotected terminals. A Canadian hydro plant reported a 50% reduction in terminal-related maintenance after adopting GE IS200ECTBG1ADE, extending the interval between service visits from 6 months to 1 year.

Related Products

GE IS200EPSMG2ADC: Exciter power supply module that delivers 24V DC to GE IS200ECTBG1ADE, ensuring stable operation during voltage fluctuations.

GE IS200EROCH1ADD: Exciter regulator options card that receives conditioned signals from GE IS200ECTBG1ADE, enabling ground fault detection and voltage regulation.

GE IS200EXHSG3AEC: High-speed ground detection module that relies on GE IS200ECTBG1ADE for terminal connections to rotor/stator winding sensors.

GE IS200EPDMG1ABA: Exciter power distribution module that supplies redundant 24V DC to GE IS200ECTBG1ADE, preventing power-related signal loss.

GE IS200EISBH1AAB: Excitation communication module that pairs with GE IS200ECTBG1ADE to transmit terminal board status data via fiber-optic ISBus.

GE IS200ECTBG1ADF: Upgraded variant of GE IS200ECTBG1ADE with 24 channels (12 analog, 12 digital) for larger excitation systems.

GE IS200TBCIH1B: Mixed-signal terminal board that complements GE IS200ECTBG1ADE by adding thermocouple support for turbine bearing temperature sensors.

GE IC660HHM501: Handheld monitor used to test signal continuity across GE IS200ECTBG1ADE’s terminals, enabling on-site troubleshooting.

IS200ECTBG1ADE

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200ECTBG1ADE, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and EX2100 firmware. Gather ESD-safe tools (anti-static wristband, insulated pliers) to protect the module’s terminals, and prepare shielded twisted-pair cables (22-14 AWG) for analog signals to minimize EMI. Label all wires to match GE IS200ECTBG1ADE’s terminal markings (e.g., “AI-FIELD-CURRENT” for analog input 1) to avoid cross-wiring, which could corrupt excitation data.

Maintenance recommendations: Perform monthly visual inspections of GE IS200ECTBG1ADE to check for loose terminal blocks, corrosion on connectors, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on terminal contacts. Quarterly, verify signal integrity by measuring analog input levels with a multimeter and testing digital I/O functionality via the Mark VI/VIe HMI. If a fault is detected (red LED), power down the associated excitation circuit before replacing GE IS200ECTBG1ADE—always use a factory-calibrated unit to ensure compatibility with EX2100 signal protocols.

Product Guarantee

GE guarantees the reliability and performance of GE IS200ECTBG1ADE with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe and EX2100 systems and can assist with installation guidance, signal troubleshooting, and configuration of GE IS200ECTBG1ADE. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200ECTBG1ADE’s signal conditioning, terminal integrity, and compatibility with excitation system components. Additionally, GE provides repair services for GE IS200ECTBG1ADE, including terminal block testing and EMI filter calibration in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.