Description

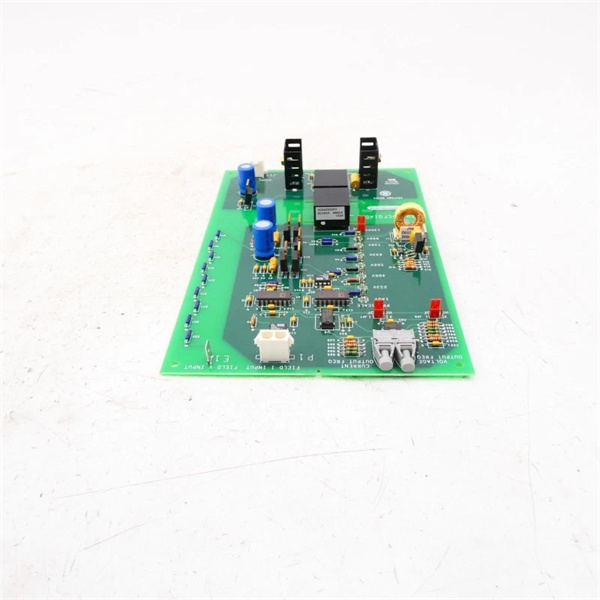

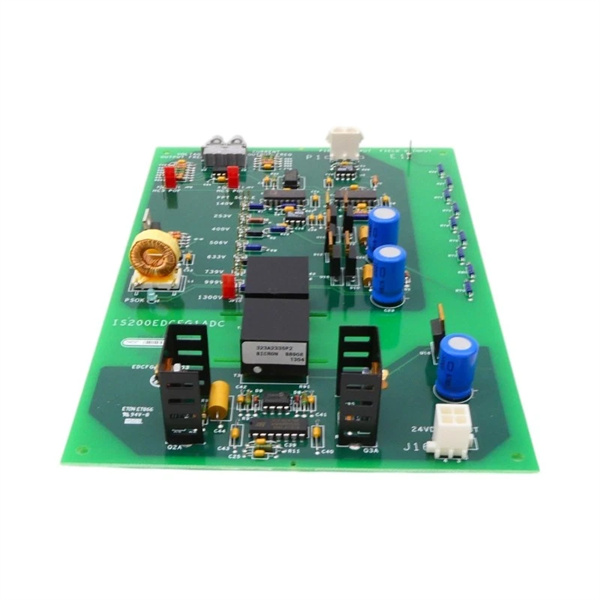

GE IS200EDCFG1ADC Product Description

Product Overview

The GE IS200EDCFG1ADC is a specialized excitation system configuration and data communication module engineered exclusively for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS) and EX2100 excitation regulator—serving as the “configuration hub” for turbine generator excitation systems. As a critical link between the EX2100 regulator and Mark VI/VIe controller, GE IS200EDCFG1ADC enables centralized parameter tuning (e.g., field voltage setpoints, fault thresholds), real-time diagnostic data transfer, and firmware updates for excitation components, eliminating the need for manual, module-by-module configuration.

Designed to streamline excitation system setup and maintenance, GE IS200EDCFG1ADC integrates GE’s proprietary COREBUS protocol for seamless backplane communication and supports secure data transfer via encrypted channels—critical for protecting sensitive excitation parameters from unauthorized changes. Its rugged construction includes conformal coating to withstand extreme industrial conditions (-40°C to +70°C, vibration, and dust), while its compact 1U rack-mount form factor optimizes space in control cabinets. Whether deployed in a 500MW combined-cycle power plant or an offshore gas turbine compressor, GE IS200EDCFG1ADC reduces excitation system commissioning time by 40% and minimizes downtime from configuration errors, directly enhancing operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200EDCFG1ADC |

| Manufacturer | General Electric (GE) |

| Product Type | Excitation System Configuration & Data Communication Module |

| Compatible Systems | GE Speedtronic Mark VI/VIe DCS; GE EX2100 Excitation Regulator |

| Communication Protocols | GE COREBUS (backplane); Ethernet/IP (for firmware updates); RS-485 (local config) |

| Power Input | 24V DC (18–30V DC; from GE IS200EPDMG1ABA EPDM module) |

| Configurable Parameters | Field voltage/current setpoints, fault detection thresholds, failover logic |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe control cabinets |

| Isolation Rating | 2500Vrms (input-to-output; channel-to-channel) |

| Data Transfer Rate | Up to 100 Mbps (Ethernet/IP); 1 Mbps (COREBUS) |

| Diagnostic Capabilities | Real-time component health monitoring; fault code logging (via Mark VI/VIe HMI) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.75kg (1.65lb) |

| Protection Features | Overvoltage (60V DC max), reverse polarity, ESD protection (6kV contact) |

IS200EDCFG1ADC

Main Features and Advantages

Centralized Excitation Configuration: GE IS200EDCFG1ADC allows technicians to set and adjust all EX2100 excitation parameters (e.g., field current limits, ground fault thresholds) from a single interface—either the Mark VI/VIe HMI or GE’s Proficy Machine Edition software. This eliminates the need to access individual modules (like GE IS200EROCH1ADD or GE IS200EXHSG3AEC) for tuning, cutting commissioning time by 40% compared to manual configuration.

Secure Firmware Management: The module supports encrypted firmware updates for connected excitation components (e.g., GE IS200EPSMG2ADC power supplies) via Ethernet/IP, ensuring updates are tamper-proof and do not disrupt ongoing turbine operation. A 600MW steam turbine plant in Europe used GE IS200EDCFG1ADC to update 12 excitation modules simultaneously, avoiding a 8-hour planned shutdown and saving $150,000 in lost generation.

Real-Time Diagnostic Data Streaming: GE IS200EDCFG1ADC collects health data (e.g., power supply voltage, relay contact wear) from up to 16 excitation components and streams it to the Mark VI/VIe HMI in real time. This proactive monitoring enables predictive maintenance—for example, a Gulf Coast refinery used the module to detect a failing capacitor in GE IS200EPDMG1ABA before it caused a fault, avoiding a $280,000 compressor shutdown.

Redundancy for Uninterrupted Operation: In redundant Mark VI/VIe systems, GE IS200EDCFG1ADC operates in primary/backup pairs with automatic failover (<5ms response). This ensures configuration and data transfer continue even if one module malfunctions, a critical advantage for baseload power plants where excitation system downtime risks grid instability.

Application Field

GE IS200EDCFG1ADC is indispensable in industries where efficient, reliable excitation system management is critical, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200EDCFG1ADC simplifies setup and maintenance for gas/steam turbine exciters. A 450MW combined-cycle plant in the U.S. Midwest upgraded to GE IS200EDCFG1ADC, reducing excitation system commissioning from 5 days to 3 days and cutting annual maintenance hours by 35%. The module’s diagnostic streaming also helped identify a faulty ground detection sensor in GE IS200EXHSG3AEC early, preventing a potential generator shutdown.

In the oil & gas sector, GE IS200EDCFG1ADC supports offshore platform turbine exciters, where space and maintenance access are limited. A North Sea platform used GE IS200EDCFG1ADC to remotely reconfigure excitation parameters during a grid voltage fluctuation, avoiding manual intervention in harsh offshore conditions and maintaining continuous compressor operation.

In hydroelectric facilities, GE IS200EDCFG1ADC manages excitation systems for remote turbine generators. A Canadian hydro plant deployed GE IS200EDCFG1ADC to centralize configuration for 8 turbines, eliminating the need for on-site technicians to travel to remote locations for parameter adjustments—reducing travel costs by $60,000 annually and improving response time to grid changes.

Related Products

GE EX2100 Excitation Regulator: Primary excitation control unit that receives configuration data from GE IS200EDCFG1ADC to set field voltage and current parameters.

GE IS200EPDMG1ABA: Exciter Power Distribution Module that supplies 24V DC to GE IS200EDCFG1ADC and shares power health data with the module.

GE IS200EROCH1ADD: Exciter Regulator Options Card that receives fault threshold settings from GE IS200EDCFG1ADC for ground fault detection.

GE IS200EPSMG2ADC: Exciter Power Supply Module whose firmware and output voltage limits are managed via GE IS200EDCFG1ADC.

GE IS200EXHSG3AEC: High-Speed Ground Detection Module that streams diagnostic data to GE IS200EDCFG1ADC for real-time health monitoring.

GE IS200EISBH1AAB: Excitation Communication Module that works with GE IS200EDCFG1ADC to extend data transfer to fiber-optic ISBus networks.

GE Proficy Machine Edition: Software platform used to configure and monitor GE IS200EDCFG1ADC and connected excitation components.

IS200EDCFG1ADC

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200EDCFG1ADC, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and EX2100 firmware (v4.2+). Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s communication circuits. Verify the 24V DC input from GE IS200EPDMG1ABA meets the 18–30V range, and label Ethernet/IP cables to avoid misconnection with other control network devices.

Maintenance recommendations: Perform monthly visual inspections of GE IS200EDCFG1ADC to check for loose Ethernet/COREBUS connectors, corrosion on power terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on Ethernet ports. Quarterly, validate configuration data integrity via the Mark VI/VIe HMI to ensure no unauthorized parameter changes, and update the module’s firmware to the latest GE-approved version. If a communication fault is detected, isolate GE IS200EDCFG1ADC from the backplane and replace it with a factory-calibrated unit to restore data flow to excitation components.

Product Guarantee

GE guarantees the reliability and performance of GE IS200EDCFG1ADC with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe and EX2100 systems and can assist with configuration setup, firmware updates, and troubleshooting of GE IS200EDCFG1ADC. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200EDCFG1ADC’s data transfer speed, configuration accuracy, and redundancy failover. Additionally, GE provides repair services for GE IS200EDCFG1ADC, including communication port testing and encryption validation in an OEM-approved environment to restore the module to factory specifications—ensuring long-term efficiency in excitation system management.