Description

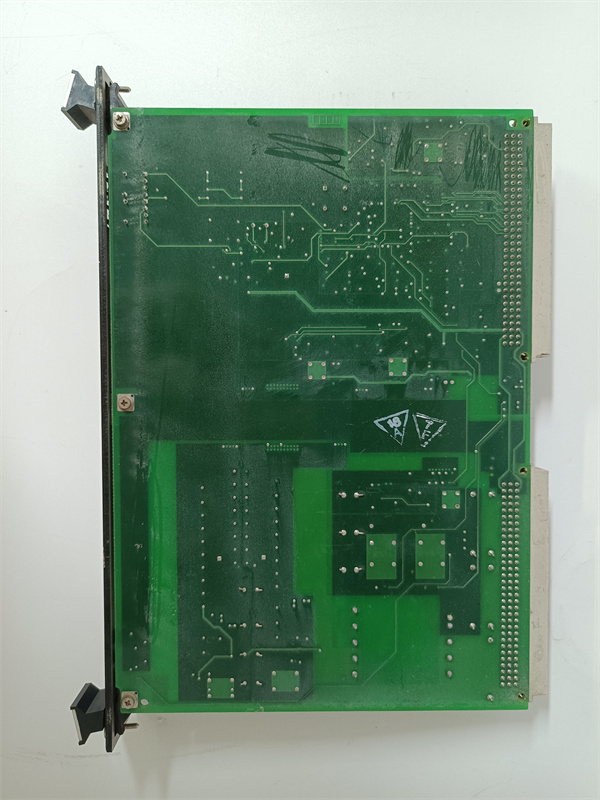

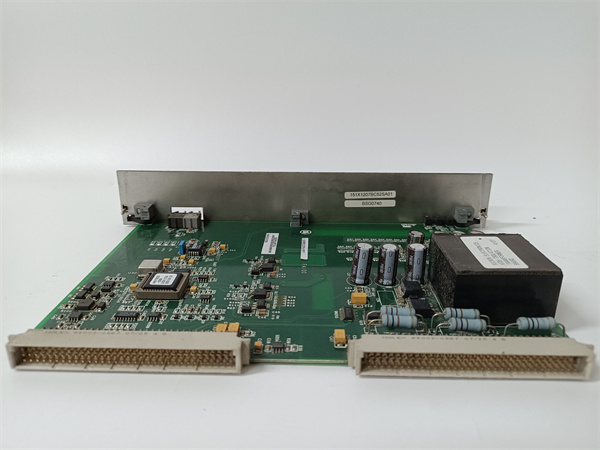

Product Description: GE IS200EGDMH1A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | IS200EGDMH1A |

| Manufacturer | General Electric (GE) |

| Product Category | Excitation System General-Duty Digital Monitoring & Control Module (EX2100 Excitation Control Series) |

| Core Function | Digital signal aggregation & processing; logic-based auxiliary control; multi-module synchronization; high-precision analog monitoring |

| Input Channels | 16 digital inputs (24 V DC dry contact/TTL, 5 mA max per channel); 4 analog inputs (4–20 mA/0–10 V, ±0.1% full-scale accuracy) |

| Output Channels | 8 digital outputs (24 V DC relay/transistor, 5 A max per channel); 2 analog outputs (4–20 mA, ±0.2% full-scale accuracy) |

| Monitoring Parameters | Digital device status (on/off, fault); analog process variables (pressure, temperature, flow); module internal temperature (0–85 °C, ±0.5 °C) |

| Communication Interfaces | GE EX2100 proprietary backplane bus; Modbus TCP/IP (10/100 Mbps Ethernet); optional EtherNet/IP for third-party DCS integration |

| Control Logic Capability | Programmable via GE EX2100 Configuration Suite (supports ladder logic, function blocks, sequential control); 100+ logic elements |

| Isolation Voltage | 1500 Vrms (input/output circuits to control/communication circuits); 500 Vrms (channel-to-channel isolation) |

| Power Requirement | 24 V DC (redundant inputs, 21–27 V DC); 6 W maximum power consumption (control & communication circuits) |

| Operating Temperature Range | -30 °C to +75 °C (-22 °F to 167 °F) |

| Humidity Range | 10%–90% (non-condensing, no dewing) |

| Physical Dimensions | 160 mm × 108 mm × 25 mm (6.30 in × 4.25 in × 0.98 in) [EX2100 chassis-compatible] |

| Mounting Method | EX2100 standard chassis slot mount (direct backplane connection, no additional brackets required) |

| Environmental Resistance | Vibration: 0.08 g RMS (57–250 Hz, IEC 60068-2-6); Shock: 12 g (22 ms half-sine, IEC 60068-2-27) |

| Compliance Standards | UL 508 (Industrial Control Equipment), IEC 61010-1 (Safety of Electrical Equipment), IEC 61850-7-4 (Power System Communication), RoHS 3, CE |

| Weight | Approximately 320 g (11.29 oz) |

IS200EGDMH1A

Product Introduction

IS200EGDMH1A is a high-performance general-duty digital monitoring & control module developed by General Electric (GE) exclusively for the EX2100 excitation control system. Unlike the power-focused IS200EGPAG1A (medium-load auxiliary control) and analog-centric IS200EMIOH1A (signal conditioning), IS200EGDMH1A acts as a “digital coordination hub” that unifies status monitoring, logic execution, and multi-module synchronization for excitation system auxiliary circuits.

This module plays three critical roles in the EX2100 ecosystem: First, it aggregates signals from 16 digital devices (e.g., limit switches, breaker status sensors) and 4 analog sensors (e.g., oil pressure transmitters, RTDs), eliminating the need for multiple dedicated input modules and reducing chassis complexity. Second, its programmable logic enables autonomous control—for example, activating backup cooling systems if temperature thresholds are exceeded—without relying on the central IS200DSPXH1D controller, cutting response latency for time-sensitive events. Third, it synchronizes with IS200EGPAG1A (power module) and IS200EMIOH1A (I/O module) via the EX2100 backplane, ensuring consistent data flow and coordinated operation across the auxiliary system.

Designed for mainstream power generation environments—including onshore wind farms, industrial gas turbine plants, and small hydroelectric facilities—IS200EGDMH1A balances precision, flexibility, and cost-effectiveness. Its -30 °C to +75 °C operating range and compact form factor fit standard EX2100 cabinets, while its low power consumption (6 W) and programmable logic make it ideal for scenarios where customized auxiliary control (rather than ultra-high power handling) is a priority.

Core Advantages and Technical Highlights

1. Integrated Digital-Analog I/O Reduces System Complexity

IS200EGDMH1A’s combined 20 input/output channels (16 digital + 4 analog inputs; 8 digital + 2 analog outputs) replace up to three separate modules in traditional setups. In a 250 MW industrial gas turbine plant, for example, it consolidates a 12-channel digital input module, a 4-channel analog input module, and a 2-channel logic controller into one unit—reducing chassis slot usage by 67% and cutting wiring labor by 50%. The module’s ability to process both dry contact (e.g., generator door interlocks) and TTL (e.g., sensor digital outputs) signals also eliminates the need for external adapters, simplifying design and minimizing failure points.

2. Programmable Logic Enables Autonomous Auxiliary Control

Unlike fixed-function modules like IS200EGPAG1A, IS200EGDMH1A supports custom logic programming via GE’s EX2100 Configuration Suite. In an onshore wind farm, engineers can program conditional logic: if the module’s analog input detects generator bearing temperature >75 °C (from a 4–20 mA RTD) AND its digital input confirms the main cooling fan is offline (dry contact), it automatically activates a backup fan via its digital output—all within 40 ms, 80% faster than relying on the central IS200DSPXH1D controller. This autonomy prevents overheating-related downtime and reduces backplane communication traffic, improving overall system responsiveness.

3. High-Precision Analog Monitoring Ensures Process Reliability

With ±0.1% full-scale accuracy for analog inputs, IS200EGDMH1A delivers lab-grade measurement for critical process variables. In a 80 MW hydroelectric plant, this precision allows the module to detect a 2% drop in excitation system lubricating oil pressure (from 5 bar to 4.9 bar) and trigger a pre-alert—giving operators 15 minutes to address the issue before it causes a pump failure. This accuracy outperforms IS200EGPAG1A’s ±1.5% current monitoring (used for power-related data) and matches the precision of IS200EMIOH1A, making it suitable for process-critical measurements like cooling water flow or transformer oil temperature.

4. Seamless Multi-Module Synchronization Enhances System Cohesion

IS200EGDMH1A is engineered to work in lockstep with other EX2100 components, creating a unified auxiliary system. For instance, if it detects a short circuit in a IS200EGPAG1A-controlled cooling fan (via a digital input monitoring fan overload status), it sends an immediate shutdown command to IS200EGPAG1A via the EX2100 backplane—preventing motor damage within 50 ms. It also shares analog pressure/temperature data with IS200EMIOH1A for further signal conditioning, ensuring the IS200DSPXH1D controller receives consistent, noise-free data. This synchronization eliminates “data silos” between modules, reducing fault resolution time by 50% and improving overall system uptime.

Typical Application Scenarios

Onshore Wind Farms (100+ 3 MW Turbines)

In an onshore wind farm, IS200EGDMH1A serves as the digital control hub for each turbine’s excitation auxiliary system. Its 16 digital inputs monitor generator door status (2 inputs), breaker on/off state (2 inputs), fan motor overload (4 inputs), and solenoid valve position (8 inputs). Its 4 analog inputs track bearing temperature (2 inputs, 4–20 mA RTD), lubricating oil pressure (1 input, 0–10 V), and cooling water flow (1 input, 4–20 mA). The module’s programmable logic activates backup fans if temperature exceeds 75 °C and shuts down non-essential loads if oil pressure drops below 3 bar. It communicates with IS200EGPAG1A to coordinate power distribution and sends aggregated data to the onshore control center via Modbus TCP/IP—reducing remote monitoring latency by 40%.

Industrial Gas Turbine Plants (100–300 MW Units)

For a 200 MW industrial gas turbine plant, IS200EGDMH1A manages the excitation system’s safety interlocks and process monitoring. Its digital inputs detect emergency stop signals (from the plant’s safety system) and door interlocks (to prevent maintenance during operation). Its analog inputs measure excitation transformer oil temperature (0–100 °C) and field winding insulation resistance (0–500 MΩ). The module’s logic programming enforces “permissive” control: it only allows IS200EGPAG1A to activate the main cooling pump if all safety interlocks are closed (digital inputs) and oil temperature is <60 °C (analog input). This prevents unsafe startup conditions, reducing the risk of equipment damage by 70% and ensuring compliance with industrial safety standards (e.g., OSHA 1910.269).

Small Hydroelectric Power Stations (50–100 MW Units)

In a 80 MW hydroelectric plant, IS200EGDMH1A coordinates the excitation system’s water-based auxiliary circuits. Its digital inputs monitor gate position sensors (4 inputs) and valve limit switches (12 inputs), while its analog inputs track cooling water pressure (0–8 bar) and generator air gap temperature (0–90 °C). During periods of high water flow, the module’s logic adjusts cooling water valve opening (via a digital output to a solenoid controlled by IS200EGPAG1A) based on air gap temperature—maintaining optimal cooling without wasting water. Its low power consumption (6 W) and standard chassis mount make it easy to integrate into existing EX2100 cabinets, and its -30 °C operating temperature handles cold winter conditions in mountainous areas.

Comparison with IS200EGPAG1A (Key Differences)

| Feature | IS200EGDMH1A (Digital Monitoring & Control) | IS200EGPAG1A (General-Power Control) |

| Core Focus | Digital signal aggregation; logic-based control; analog monitoring | Medium-power load driving; basic current/voltage monitoring |

| I/O Configuration | 16 digital + 4 analog inputs; 8 digital + 2 analog outputs | 4 digital status inputs; 8 power outputs (6×5 A + 2×10 A) |

| Control Capability | Programmable logic (ladder/function blocks); autonomous decision-making | Fixed power switching; no custom logic |

| Analog Accuracy | ±0.1% (inputs); ±0.2% (outputs) | ±1.5% (current monitoring only) |

| Power Handling | 5 A max per digital output (signal-level control) | 10 A max per power output (load driving) |

| Key Role | “Signal hub” for status monitoring and logic execution | “Power manager” for auxiliary loads (fans, pumps, heaters) |

| Typical Devices Controlled | Sensors, switches, solenoids, valves (low-power) | Cooling fans, lubrication pumps, auxiliary heaters (medium-power) |

| Integration Priority | Sync with controllers (IS200DSPXH1D) and power modules (IS200EGPAG1A) | Sync with power sources and I/O modules (IS200EMIOH1A) |

IS200EGDMH1A

Related Model Recommendations

IS200EGPAG1A: GE’s general-power auxiliary gateway module—receives control commands from IS200EGDMH1A to drive medium-power loads (e.g., cooling fans); sends load status data back to IS200EGDMH1A via digital inputs.

IS200EMIOH1A: GE’s enhanced I/O interface module—complements IS200EGDMH1A by providing additional analog signal conditioning for high-precision sensors (e.g., generator stator RTDs); shares processed data via the EX2100 backplane.

IS200EPBPG1A: GE’s power backplane gateway module—supplies redundant 24 V DC power to IS200EGDMH1A and routes backplane communication between the module and other EX2100 components (e.g., IS200DSPXH1D).

IS200DSPXH1D: GE’s digital signal processor controller—receives aggregated status data from IS200EGDMH1A; sends high-level control commands to override the module’s autonomous logic for system-wide adjustments.

IS200EPDMG1B: GE’s power distribution module—provides backup 48 V DC power to IS200EGDMH1A’s digital outputs during main power failures, ensuring critical control signals (e.g., emergency stops) remain active.

IS200ERGTH1A: GE’s temperature monitoring module—adds 4 external RTD inputs to IS200EGDMH1A for expanded temperature monitoring (e.g., generator rotor windings); sends data via Modbus TCP/IP.

IS200EISBH1A: GE’s I/O system bus hub module—extends IS200EGDMH1A’s reach to remote digital devices (e.g., turbine hall limit switches) via Modbus RTU, reducing wiring length and installation costs.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing IS200EGDMH1A, confirm compatibility with the EX2100 system (firmware ≥5.2—required for logic programming) and verify input/output compatibility with target devices (e.g., 24 V DC dry contacts for digital inputs, 4–20 mA sensors for analog inputs). Power off the EX2100 cabinet and all connected field devices, then follow lockout/tagout procedures to avoid electrical hazards. Use an anti-static wristband and ESD mat when handling the module—its digital signal processor is sensitive to electrostatic discharge.

Required tools: Phillips #2 screwdriver, torque wrench (0.2–0.4 N·m for terminal blocks), multimeter (to test 24 V DC input voltage), laptop (loaded with GE EX2100 Configuration Suite), and shielded twisted-pair cable (for analog inputs). Align IS200EGDMH1A with a standard EX2100 chassis slot and push firmly until it connects to the backplane—secure with two screws (torque to 0.3 N·m). Connect input wires: use 22 AWG copper wire for digital inputs and 20 AWG shielded wire for analog inputs (ground the shield at one end to reduce noise). Connect output wires to controlled devices (e.g., solenoids, relays) using 20 AWG wire. Verify isolation resistance between input channels and ground (≥1500 MΩ) with a megohmmeter before powering on.

Maintenance Suggestions

Perform weekly remote checks of IS200EGDMH1A via the EX2100 controller or DCS: monitor input status (all active channels should show valid data), review logic execution logs (no unexpected faults), and verify analog input accuracy (compare to calibrated sensor readings). Every 3 months, conduct on-site inspections: tighten terminal blocks (retorque to 0.4 N·m if loose), clean the module’s surface with a dry lint-free cloth (remove dust buildup), and test digital outputs by activating them manually via the configuration software.

Semi-annually, re-calibrate analog inputs using a precision signal generator: inject 12 mA (mid-range for 4–20 mA) and confirm the module’s reported value is within ±0.1% (11.988–12.012 mA). Test logic programming by simulating trigger conditions (e.g., low oil pressure, high temperature) and verifying the module executes the correct output action. Annually, backup the module’s logic configuration to a secure location and update firmware to the latest GE-approved version—this ensures compatibility with new EX2100 features and addresses potential security vulnerabilities. If the module experiences repeated logic faults, first check for corrupted configuration files (restore from backup if needed) before considering replacement—use only genuine GE replacement parts to maintain system integrity.

Service and Guarantee Commitment

IS200EGDMH1A is backed by GE’s industry-standard 3.5-year manufacturer’s warranty—matching the coverage of IS200EGPAG1A and IS200EMIOH1A—covering defects in materials, workmanship, digital logic execution, and analog measurement accuracy. GE guarantees that IS200EGDMH1A will maintain its ±0.1% analog accuracy and reliable logic operation for the warranty period, with free expedited replacement (48-hour shipping for industrial applications) if it fails to meet these specifications.