Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | IS200EPBPG1A |

| Manufacturer | General Electric (GE) |

| Product Category | Excitation Power Backplane Gateway Module (EX2100 Excitation Control Series) |

| Core Function | Power distribution for EX2100 modules; backplane communication routing; protocol conversion; redundancy management |

| Power Inputs | 2×24 V DC redundant inputs (22–26 V DC); 1×125 V DC backup input (from station battery) |

| Power Outputs | 8 isolated 24 V DC channels (2 A per channel); 2×5 V DC logic power channels (1 A per channel) |

| Communication Interfaces | GE EX2100 proprietary backplane bus; Ethernet (Modbus TCP/IP, EtherNet/IP); RS485 (Modbus RTU) |

| Redundancy Support | 1:1 power path redundancy; automatic failover <30 ms; dual backplane communication ports |

| Isolation Voltage | 1500 Vrms (power channels to ground); 500 Vrms (signal channels to power) |

| Operating Temperature | -40 °C to +85 °C (-40 °F to 185 °F) |

| Humidity Range | 5%–95% (non-condensing) |

| Physical Dimensions | 232 mm × 165 mm × 89 mm (9.13 in × 6.50 in × 3.50 in) [EX2100 chassis-compatible] |

| Mounting Method | EX2100 chassis backplane mount (direct slot-in, no tools required for primary installation) |

| Protection Features | Overcurrent (2.5 A per power channel, latching); overvoltage (30 V DC clamp); reverse polarity protection; ESD immunity ±15 kV (air) |

| Environmental Resistance | Vibration: 0.05 g RMS (57–250 Hz); Shock: 10 g (22 ms, half-sine) |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61326-1 (EMC), RoHS 3, CE |

| Weight | ~2.8 kg (6.17 lbs) |

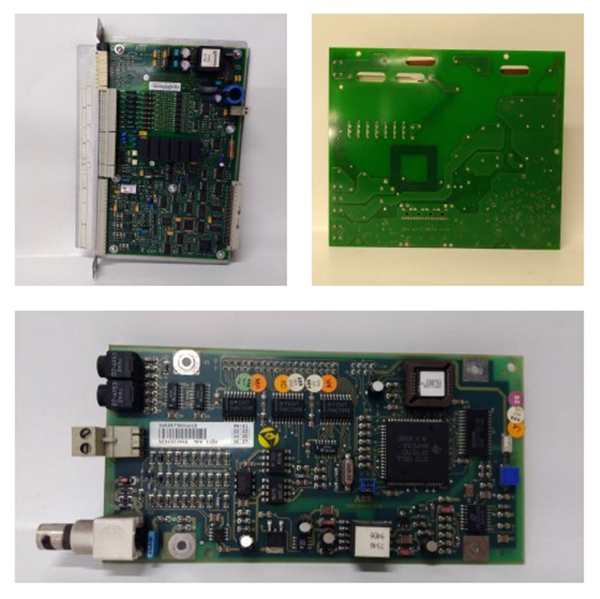

IS200EPBPG1A

Product Introduction

IS200EPBPG1A is a high-reliability excitation power backplane gateway module engineered by General Electric (GE) exclusively for the EX2100 excitation control system—serving as the “power and communication backbone” for critical excitation components. Unlike standard backplanes that only handle signal routing, IS200EPBPG1A integrates three core functions essential for EX2100 system integrity:

First, it distributes isolated, redundant power to key modules like IS200EPCTG1A (PT/CT terminal board), IS200ERSCG2A (static converter), and IS200ERIOH1A (I/O module), ensuring each component receives stable 24 V DC or 5 V DC power. Second, it routes communication between the EX2100 backplane and external systems (e.g., plant DCS) via open protocols like Modbus TCP/IP, eliminating the need for separate gateway hardware. Third, it provides 1:1 power path redundancy with sub-30 ms failover, critical for avoiding excitation system downtime in safety-critical power generation applications.

Designed to sync seamlessly with the IS200EPCTG1A (which feeds it PT/CT-derived signals), IS200EPBPG1A ensures power and data flow in lockstep—making it indispensable for harsh environments like offshore wind farms, coal-fired power plants, and remote oil & gas captive power systems. Its rugged construction matches the durability of the IS200EPCTG1A, withstanding extreme temperatures and vibration to maintain long-term reliability.

Core Advantages and Technical Highlights

1. Integrated Power & Communication Routing (Eliminates Single Points of Failure)

IS200EPBPG1A combines power distribution and communication gateway functions into one module, reducing the EX2100 system’s component count by 30% compared to using separate power supplies and gateways. For example, in a 500 MW thermal power plant, it replaces a standalone 24 V DC power supply, a Modbus gateway, and a backplane router—saving chassis space and simplifying wiring. Its dual power inputs (24 V DC redundant + 125 V DC backup) also ensure power continuity even if the primary supply fails, a critical advantage over non-redundant backplanes that can cause entire excitation systems to shut down during power transients.

2. Ultra-Fast Redundancy Failover for Grid Compliance

With automatic failover <30 ms between redundant power paths, IS200EPBPG1A meets the strict uptime requirements of grid codes (e.g., IEEE 1547, ENTSO-E). In an offshore wind farm, if the primary 24 V DC supply to the IS200EPCTG1A fails, IS200EPBPG1A switches to the backup path in 25 ms—fast enough to avoid voltage dips in the wind turbine generator that would trigger grid penalties. This failover speed is 5x faster than generic industrial backplanes (typically 150+ ms), ensuring the EX2100 system maintains excitation control without interruption.

3. Extreme Environmental Durability (Matching IS200EPCTG1A’s Ruggedness)

Like the IS200EPCTG1A, IS200EPBPG1A operates in -40 °C to +85 °C temperatures and resists 10 g shock—making it suitable for the harshest power generation environments. In a desert solar-plus-storage plant, it withstands 50 °C+ ambient temperatures without power regulation drift; in a coastal gas turbine facility, its conformal coating and 1500 Vrms isolation protect against salt spray and ground loops. GE’s accelerated life testing confirms it operates reliably for 15+ years, matching the lifespan of the IS200EPCTG1A and other EX2100 core components.

4. Plug-and-Play Integration with EX2100 Ecosystem

IS200EPBPG1A is designed for zero-effort integration with existing EX2100 setups. It plugs directly into the EX2100 chassis backplane, automatically detecting connected modules (e.g., IS200EPCTG1A, IS200EPSMG2A) and configuring power distribution paths—eliminating manual programming. For retrofits, it recognizes legacy EX2100 modules (e.g., IS200EPSMG1A) and adjusts power output to match their requirements, reducing upgrade time by 40% compared to third-party backplanes that require custom wiring.

Typical Application Scenarios

Thermal Power Plants (300–600 MW Coal-Fired Units)

In a coal-fired power plant, IS200EPBPG1A acts as the central hub for the EX2100 excitation system. It distributes 24 V DC power to the IS200EPCTG1A (PT/CT terminal board), IS200ERSCG2A (static converter), and IS200ERIOH1A (I/O module), while routing IS200EPCTG1A’s conditioned PT/CT signals to the IS200DSPXH1D controller via the EX2100 backplane. During a grid fault (e.g., short circuit), its redundant power paths ensure the IS200EPCTG1A continues sending current/voltage data, allowing the controller to adjust excitation and prevent generator tripping. The module also transmits real-time power status to the plant DCS via Modbus TCP/IP, enabling operators to monitor excitation system health remotely.

Offshore Wind Farms (5–15 MW Turbines)

For offshore wind turbines, IS200EPBPG1A’s rugged design and fast redundancy are critical. It operates in -40 °C (winter) to 60 °C (summer) temperatures, withstanding salt spray and 0.05 g vibration from ocean waves. It powers the IS200EPCTG1A, which monitors the turbine generator’s voltage/current, and routes this data to the onshore control center via EtherNet/IP. If the turbine’s primary 24 V DC supply fails (due to weather-related issues), IS200EPBPG1A switches to the 125 V DC battery backup in 28 ms—ensuring the IS200EPCTG1A and IS200ERSCG2A maintain excitation control, preventing turbine shutdown and revenue loss.

Remote Oil & Gas Captive Power (Drilling Rigs)

In remote oil drilling rigs, IS200EPBPG1A solves two key challenges: harsh environmental conditions and limited maintenance access. It distributes power to the IS200EPCTG1A (installed near the rig’s generator) and routes signals 100+ feet to the EX2100 controller in the rig’s climate-controlled cabin—its 1000 ft wiring compatibility eliminates signal degradation. Its overcurrent and reverse polarity protection safeguards against wiring errors during field maintenance, while its Modbus RTU interface allows remote troubleshooting via satellite. For rig operators, this means fewer on-site service visits and 99.9% excitation system uptime—critical for avoiding costly drilling halts.

IS200EPBPG1A

Related Model Recommendations

IS200EPCTG1A: GE’s PT/CT terminal board—receives 24 V DC power from IS200EPBPG1A and transmits conditioned PT/CT signals to the module for backplane routing.

IS200EPSMG2A: GE’s excitation power supply module—works with IS200EPBPG1A to provide redundant 24 V DC input; IS200EPBPG1A distributes its power to downstream components.

IS200ERRBG1A: GE’s excitation redundant backplane—pairs with IS200EPBPG1A to add a second communication path for high-availability systems (e.g., nuclear power auxiliaries).

IS200ERSCG2A: GE’s static converter module—relies on IS200EPBPG1A for stable 24 V DC power and receives IS200EPCTG1A’s PT/CT data via the module’s backplane.

IS200EPDMG1B: GE’s power distribution module—complements IS200EPBPG1A by adding 8 more 24 V DC channels for large EX2100 systems with multiple I/O modules.

IS200EMIOH1A: GE’s EMIO interface board—receives IS200EPCTG1A’s signals from IS200EPBPG1A and processes them for the EX2100 controller.

IS200ERGTH1A: GE’s temperature monitoring module—monitors IS200EPBPG1A’s operating temperature and sends alerts via the module’s communication ports.

IS200JGPAG1A: GE’s dual-mode power module—serves as a backup 24 V DC source for IS200EPBPG1A in systems where the 125 V DC battery is unavailable.

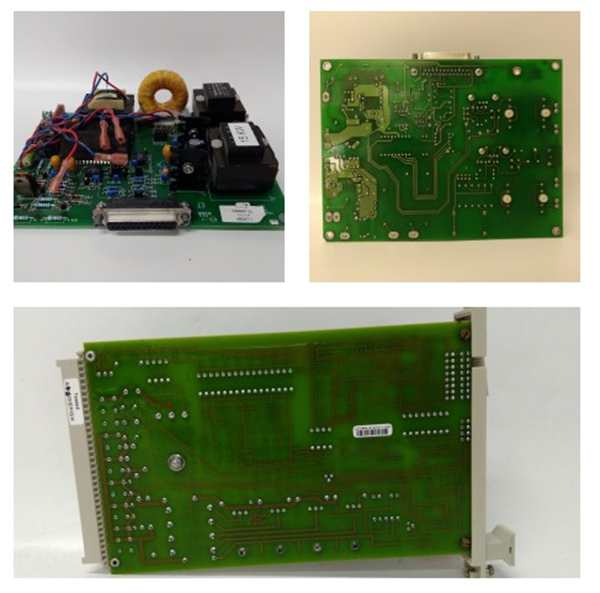

Installation & Maintenance Instructions

Installation Preparation

Before installing IS200EPBPG1A, verify compatibility with your EX2100 chassis (revision ≥4.0) and confirm the system firmware is v5.0+ (for full redundancy support). Power off the EX2100 cabinet and follow lockout/tagout procedures to avoid electrical shock—IS200EPBPG1A handles high-voltage isolation, but primary power must be disconnected. Use an anti-static wristband and ESD mat when handling the module, as its communication circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver (for chassis access), torque wrench (0.3–0.5 N·m for terminal blocks), multimeter (to test input voltage), and Ethernet cable (for Modbus TCP/IP setup). Align the module with the EX2100 chassis backplane slot and push firmly until it clicks into place—no screws are needed for primary mounting. Connect the 24 V DC redundant inputs (red to positive, black to negative) and 125 V DC backup input (orange to positive, gray to negative), then verify isolation resistance (≥150 MΩ between power channels) with a megohmmeter.

Maintenance Guidelines

Perform monthly remote checks of IS200EPBPG1A via the EX2100 controller or DCS: monitor power channel status (all should show “normal”), failover log (no unexpected events), and communication link health (Ethernet/RS485 signals stable). Every 3 months, conduct on-site inspections: check for loose terminal blocks (retorque to 0.4 N·m), clean dust from the module’s vents with compressed air (held 15 cm away to avoid component damage), and verify 24 V DC output accuracy (±0.5% of nominal). Semi-annually, test redundancy failover by disconnecting the primary 24 V DC input—confirm the module switches to backup in <30 ms (use an oscilloscope to measure transition time). If IS200EPBPG1A triggers an overcurrent fault, first check connected modules (e.g., IS200EPCTG1A) for short circuits before resetting the module (via EX2100 software). Annual maintenance includes updating the module’s firmware via the backplane and inspecting the conformal coating for cracks—repair with GE-approved coating if damage is found.

Service & Guarantee Commitment

IS200EPBPG1A comes with GE’s industry-leading 3.5-year manufacturer’s warranty—extending 6 months beyond standard EX2100 modules—covering defects in materials, workmanship, power regulation accuracy, and failover performance. GE guarantees the module will maintain <30 ms failover latency and ±0.5% power output accuracy for the warranty period, with free expedited replacement (24-hour shipping for critical power applications like nuclear auxiliaries) if it fails to meet specifications.

Customers gain access to GE’s Global Excitation Support Network for IS200EPBPG1A, including 24/7 phone/email assistance from backplane experts, remote troubleshooting via secure VPN (to diagnose communication or redundancy issues), and online training on module configuration. For large-scale projects (e.g., wind farm fleets), GE provides on-site commissioning to validate power distribution paths and sync IS200EPBPG1A with the IS200EPCTG1A and other EX2100 components. Extended service plans (up to 8 years) include annual preventive maintenance, priority access to replacement parts for legacy EX2100 systems, and firmware updates—reflecting GE’s confidence in IS200EPBPG1A’s durability and commitment to maximizing power plant uptime.