Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | IS200EPCTG1A |

| Manufacturer | General Electric (GE) |

| Product Category | PT/CT Terminal Board (EX2100 Excitation Control Series) |

| Core Function | PT/CT signal acquisition; signal isolation/conditioning; load matching |

| Input Interfaces | 2×3-phase generator PT inputs; 2×generator CT inputs (1A/5A) |

| Analog Output | 1 channel (0–10 V or 4–20 mA) |

| PT/CT Load | ≤1 VA (input side) |

| Wiring Capacity | Up to #10 AWG; max cable length 1000 ft |

| Power Requirement | Powered via EX2100 backplane (no external power needed) |

| Operating Temperature | -40 °C to +85 °C (-40 °F to 185 °F) |

| Humidity Range | 5%–95% (non-condensing) |

| Physical Dimensions | 232 mm × 165 mm × 89 mm (9.13 in × 6.50 in × 3.50 in) |

| Mounting Method | EX2100 chassis backplane mount |

| Protection Features | 500 Vrms signal isolation; ESD immunity |

| Environmental Resistance | Vibration: 0.05 g RMS (57–250 Hz); Shock: 5 g (22 ms) |

| Compliance Standards | UL 508, IEC 61010-1, RoHS 3 |

| Weight | ~2.5 kg (5.51 lbs) |

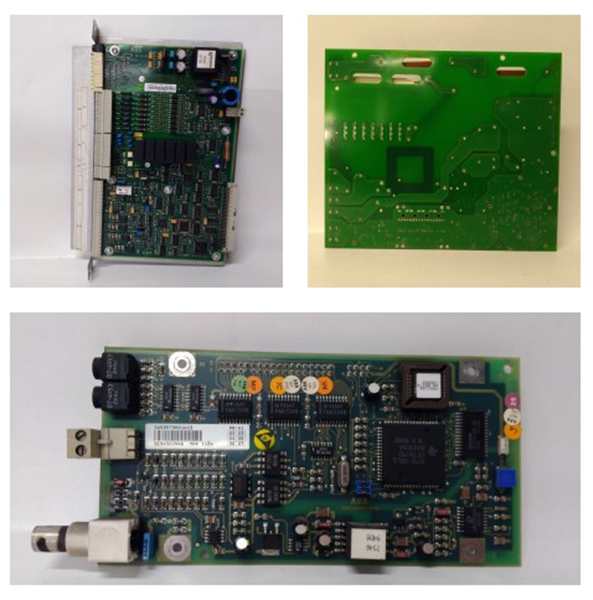

IS200EPCTG1A

Product Introduction

IS200EPCTG1A is a dedicated PT/CT terminal board developed by GE for the EX2100 excitation control system. As the “signal gateway” between field sensors and the control system, it performs three critical roles:

Signal Acquisition: Accepts inputs from 2 sets of 3-phase voltage transformers (PT) and 2 sets of current transformers (CT) installed on the generator .

Conditioning & Isolation: Scales high-voltage/current signals to standard 0–10 V/4–20 mA outputs while providing 500 Vrms isolation to prevent fault propagation .

Load Matching: Maintains input load ≤1 VA to avoid distorting PT/CT measurements .

This module directly interfaces with the EX2100 backplane and transmits conditioned signals to the EMIO board for further processing . Its rugged design makes it suitable for harsh industrial environments in power generation, oil & gas, and manufacturing .

Core Advantages and Technical Highlights

1. Precision Signal Conditioning

The board’s low-input load (≤1 VA) ensures minimal interference with PT/CT measurements, critical for accurate voltage/current feedback in excitation control. This precision enables the EX2100 system to regulate generator terminal voltage within ±0.2% of setpoint.

2. Extreme Environmental Adaptability

With an operating temperature range of -40°C to 85°C and resistance to vibration/shock, it reliably operates in desert, offshore, or high-altitude power plants . The conformal coating protects against dust and moisture in hydroelectric or coastal facilities.

3. Flexible Wiring Compatibility

Support for #10 AWG wiring and 1000 ft cable lengths allows installation in large power plant layouts without signal degradation . This flexibility simplifies retrofits of legacy excitation systems.

4. Seamless System Integration

Designed for the EX2100 ecosystem, it plugs directly into the backplane and synchronizes with components like IS200ERSCG2A (static converter) and IS200EPSMG2A (power supply) to form a closed-loop control system.

Typical Application Scenarios

Thermal Power Plants

In 300–600 MW coal-fired units, IS200EPCTG1A collects generator terminal voltage (via PT) and stator current (via CT) signals. Conditioned outputs are sent to the IS200DSPXH1D controller, which adjusts excitation current to maintain grid-compliant reactive power.

Offshore Wind Farms

For 5–15 MW wind turbines, the board’s wide temperature range (-40°C to 85°C) and vibration resistance make it ideal for marine environments. It monitors generator current/voltage to optimize excitation during wind speed fluctuations .

Oil & Gas Captive Power

In remote drilling sites, the module’s 1000 ft wiring capacity allows PT/CT installation near generators while the control cabinet is placed in a protected shelter. Signal isolation prevents ground loops in harsh grounding conditions .

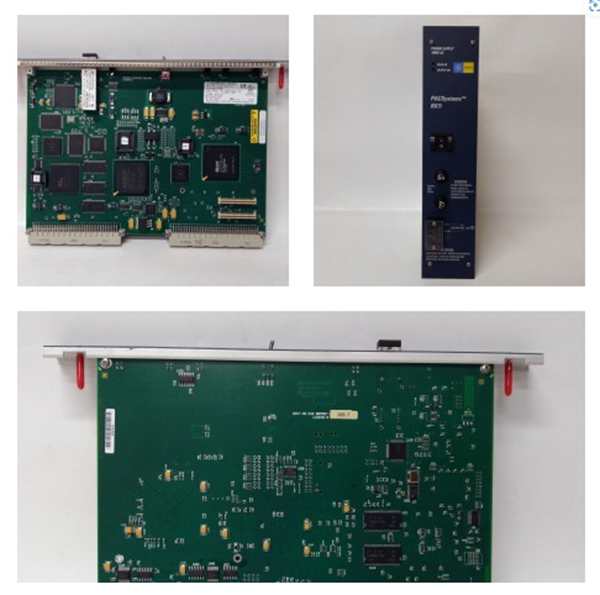

Related Model Recommendations

IS200EMIOH1A – EMIO interface board that receives conditioned signals from IS200EPCTG1A

IS200ERSCG2A – Static converter module that uses PT/CT data for PWM control

IS200EPSMG2A – Excitation power supply regulated by signals from IS200EPCTG1A

IS200ERRBG1A – Redundant backplane for dual IS200EPCTG1A deployment (high-availability systems)

IS200ERGTH1A – Temperature monitor for tracking IS200EPCTG1A’s operating status

Installation & Maintenance Instructions

Installation Preparation

Verify backplane compatibility with EX2100 series (reference GEH-6632 manual ).

Use #10 AWG copper wire for PT/CT connections; ensure cable length ≤1000 ft .

Tools required: Torque wrench (0.3–0.5 N·m), multimeter, and anti-static wristband.

Maintenance Guidelines

Quarterly: Inspect terminal screws for tightness (prevent signal loss) and clean dust with compressed air.

Semi-annually: Test isolation resistance (≥100 MΩ at 500 VDC) between channels.

Annually: Calibrate analog output (0–10 V/4–20 mA) against standard signal generator.

Caution: Always disconnect PT/CT primary circuits before servicing to avoid high-voltage hazards.

Service & Guarantee

Warranty: 3-year manufacturer warranty (covers material/workmanship defects).

Support: 24/7 global technical support via GE’s excitation system hotline.

Spare Parts: Same-day shipment for critical applications (e.g., nuclear power plants).

Extended Service: Optional 5-year maintenance contracts including calibration and firmware updates.