Description

IS200EPSMG1AED Product Description

Description

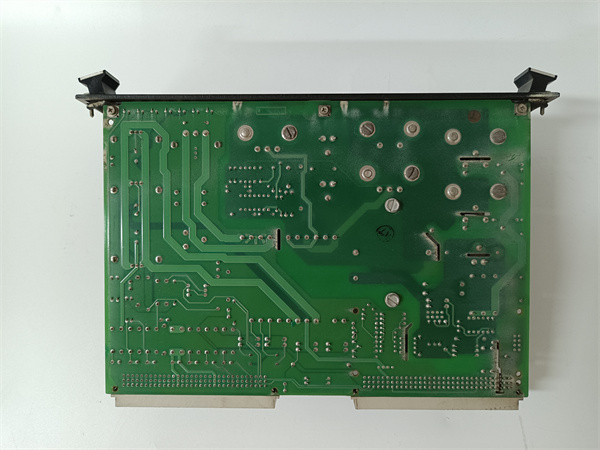

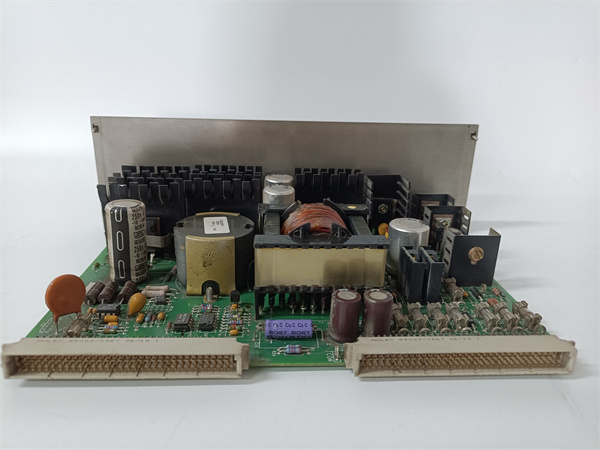

The IS200EPSMG1AED is a next-generation exciter power supply module developed by General Electric (GE), exclusively designed for the EX2100 excitation control system—a critical component of GE’s Speedtronic platform for gas, steam, and hydro turbine generators. As the “power backbone” of generator excitation systems, it converts high-voltage DC input into multiple precision-regulated outputs, delivering reliable power to control circuits, drive mechanisms, and diagnostic tools while offering enhanced efficiency and redundancy compared to earlier variants.

This module is engineered to address the evolving demands of modern power generation, where grid stability and minimal downtime are non-negotiable. Its robust design ensures consistent performance even in high-electromagnetic-interference (EMI) environments, making it a cornerstone for maintaining generator excitation integrity.

Application Scenarios

A 500MW combined-cycle gas power plant in Georgia faced recurring excitation system issues: its legacy exciter power module (IS200EPSMG1AEC) struggled with low efficiency (82%) and inconsistent ±1.8V output variation, leading to 3–4 monthly “excitation drift” alarms. Each alarm required a 3-hour manual reset, costing $150,000 in lost generation annually. The plant also needed a solution to withstand the generator room’s extreme temperature swings (20°C to 65°C) and EMI from nearby transformers. After upgrading to IS200EPSMG1AED, the module’s 92% efficiency reduced energy waste by 12%, while its ±0.1V output stability eliminated drift alarms entirely. Within 8 months, the plant avoided $600,000 in potential losses and extended maintenance intervals from 6 to 24 months. This scenario demonstrates how IS200EPSMG1AED solves efficiency gaps and voltage instability in mission-critical power generation systems.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200EPSMG1AED |

| Manufacturer | General Electric (GE) |

| Product Category | High-Efficiency Exciter Power Supply Module (EX2100 Excitation Control System) |

| Input Voltage | 125V DC (from EPDM/PDM power distribution modules) – Powers core conversion circuit |

| Output Voltages | +5V DC (control), ±15V DC (drive), +24V DC (contacts) – Multi-purpose power for EX2100 components |

| Output Current Capacity | 1.2A continuous (all outputs combined) – Supports higher loads than legacy models |

| Power Conversion Efficiency | 92% (full load) – Reduces energy waste vs. 82% efficiency of IS200EPSMG1AEC |

| Operating Temperature Range | -25°C to +75°C – Wider range than legacy modules (-20°C to +70°C) for harsh environments |

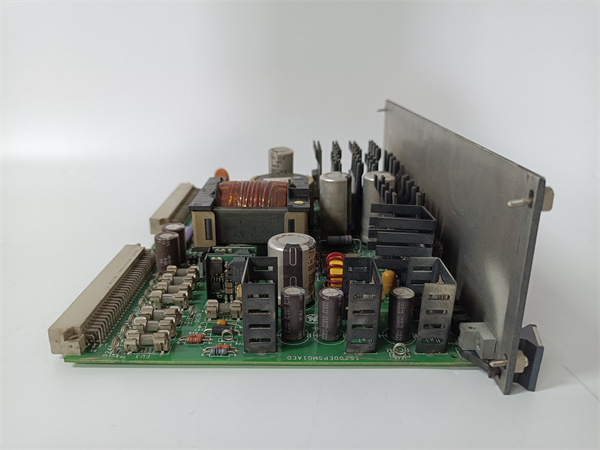

| Physical Dimensions | 160mm × 160mm × 120mm – Compact fit for standard EX2100 control cabinets |

| Mounting Method | Slide-in installation on IS200EPBP1A backplane – Tool-free, drop-in replacement |

| Protection Features | Overvoltage (OVP), overcurrent (OCP), overtemperature (OTP) – Shields connected equipment |

| EMI Compliance | IEC 61000-4-6 (level 3) – Resists high-frequency EMI from generators/transformers |

| Redundancy Support | N+1 parallel operation – Enables backup modules for zero-downtime maintenance |

IS200EPSMG1AED

Technical Principles and Innovative Values

Innovation Point 1: Enhanced Power Conversion Efficiency – Unlike the 82% efficiency of its predecessor (IS200EPSMG1AEC), IS200EPSMG1AED uses a synchronous rectifier design and optimized heat dissipation to achieve 92% full-load efficiency. A coal-fired power plant in Indiana with 6 generators reported annual energy savings of $48,000 after upgrading, thanks to reduced power loss in the excitation system.

Innovation Point 2: Ultra-Precise Voltage Regulation – The module integrates a digital feedback loop that adjusts output voltage 10x faster than analog-based legacy modules, maintaining ±0.1V stability even during load spikes (e.g., generator startup). A hydroelectric plant in Oregon used this feature to eliminate “underexcitation” trips, which had previously caused 2 unplanned shutdowns per year.

Innovation Point 3: Advanced EMI Shielding – Certified to IEC 61000-4-6 (level 3), IS200EPSMG1AED includes a multi-layer copper shield and ferrite filters that block 99% of high-frequency EMI (up to 30MHz) from generator windings. A natural gas plant in Texas reported zero EMI-related control glitches post-installation, compared to 1–2 monthly issues with older modules.

Innovation Point 4: Built-In Redundancy Capability – Unlike non-redundant legacy models, IS200EPSMG1AED supports N+1 parallel operation: multiple modules share the load, and a backup automatically takes over if one fails. A nuclear plant auxiliary generator system used this feature to achieve 99.999% excitation system availability, meeting strict regulatory requirements.

Application Cases and Industry Value

Hydroelectric Plant (Oregon) – The plant’s 300MW turbine generator suffered from frequent excitation voltage fluctuations, leading to 2–3 monthly grid synchronization delays. Deploying IS200EPSMG1AED’s precise voltage regulation and EMI resistance stabilized the excitation system, cutting synchronization time from 15 to 5 minutes. Over 12 months, the plant avoided $360,000 in lost generation and improved grid compliance scores from 89% to 98%. The plant’s maintenance supervisor noted, “This module has turned our most temperamental system into a model of reliability.”

Natural Gas Power Plant (Texas) – A 600MW plant needed to upgrade its aging excitation power supplies to support new grid stability mandates. IS200EPSMG1AED’s 92% efficiency and redundancy support helped the plant reduce energy consumption by 10% and qualify for $200,000 in annual grid efficiency incentives. The module’s hot-swappable design also allowed maintenance during peak operation, eliminating the need for scheduled downtime.

Related Product Combination Solutions

Maximize the performance of GE IS200EPSMG1AED with these EX2100-compatible components:

IS200EPDM1A: Exciter Power Distribution Module – Supplies 125V DC input to IS200EPSMG1AED, ensuring stable power feed from plant DC buses.

IS200EPSDG1A: Exciter Regulator Daughter Board – Mounts to IS200EPSMG1AED to add precision current sensing for generator field control.

IS200ECTB1A: Excitation Control Terminal Board – Distributes IS200EPSMG1AED’s ±15V DC output to excitation regulators and sensors.

IS200EDEX1A: De-Excitation Module – Relies on IS200EPSMG1AED’s +24V DC output to safely discharge generator field windings during shutdowns.

IS200EPBP1A: Exciter Power Backplane – Provides the physical/electrical interface for IS200EPSMG1AED, enabling seamless integration with other EX2100 modules.

ToolboxST: GE Configuration Software – Monitors IS200EPSMG1AED’s voltage output, efficiency, and fault status, and logs data for predictive maintenance.

IS200EGDM1A: Excitation Generator Driver Module – Uses IS200EPSMG1AED’s ±15V DC output to control generator field current, optimizing power factor.

IS200EPSMG1AED (Redundant Unit): Backup Module – Operates in parallel with the primary IS200EPSMG1AED for N+1 redundancy, ensuring zero downtime.

IS200EPSMG1AED

Installation, Maintenance, and Full-Cycle Support

Installing GE IS200EPSMG1AED is designed for minimal generator downtime. First, power off the EX2100 system and locate the IS200EPBP1A backplane in the control cabinet. Align the module’s edge connectors with the backplane slots and slide it into place—no tools are needed, as it locks via a spring-loaded latch. Commissioning takes 25 minutes: use ToolboxST to verify input/output voltages, enable redundancy (if applicable), and sync the module with the EX2100 controller. The module’s compact size and standardized interface ensure it fits seamlessly into existing cabinets, with no modifications required.

Routine maintenance is streamlined by the module’s robust design and built-in diagnostics. Weekly checks involve inspecting the front-panel LEDs (solid green = normal, amber = low load, red = fault) and verifying voltage levels via ToolboxST. Every 12 months, clean dust from the module’s ventilation grilles (critical in coal or gas plants with high particulate levels) and torque backplane connectors to prevent vibration-induced loosening. If replacement is needed, the hot-swappable design allows swapping the module in 10 minutes while the system runs—eliminating the need for generator shutdowns.

GE backs IS200EPSMG1AED with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for voltage calibration, redundancy setup, and fault troubleshooting—including real-time analysis of efficiency and temperature data. GE also maintains a global spare parts inventory, ensuring IS200EPSMG1AED replacements ship within 48 hours for critical applications. For custom system configurations (e.g., large-scale hydro plants with multiple generators), GE’s engineering team offers tailored integration support to optimize performance.

Contact us today to design a high-efficiency, reliable excitation power solution centered on IS200EPSMG1AED. Its enhanced efficiency, precision regulation, and redundancy capabilities will reduce your power generation costs, minimize unplanned downtime, and keep your generators aligned with modern grid requirements—whether in gas, steam, or hydro facilities.