Description

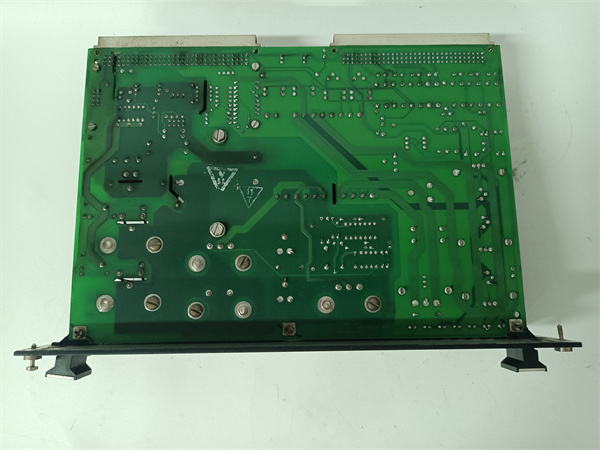

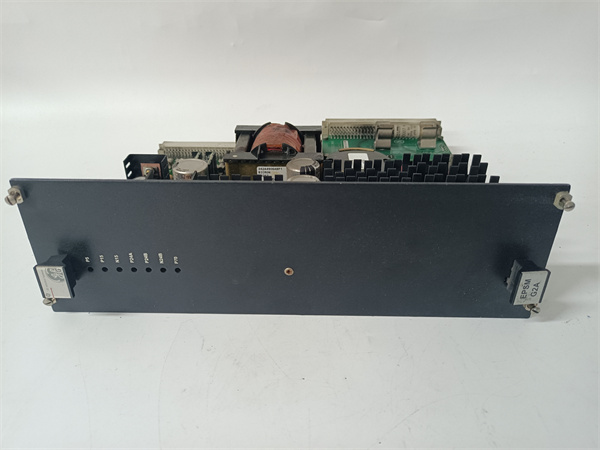

Product Description: GE IS200EPSMG2A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200EPSMG2A |

| Manufacturer | General Electric (GE) |

| Product category | Excitation Power Supply Module (EX2100 Excitation Control Series) |

| Input Voltage Range | 380–480 V AC (3-phase), 50/60 Hz (auto-sensing) |

| Output Voltage Range | 0–550 V DC (adjustable via EX2100 controller) |

| Rated Output Current | 0–500 A DC (continuous operation) |

| Rated Power | 300 kW (at full output voltage/current) |

| Conversion Efficiency | ≥96% (at 50–100% load) |

| Operating Temperature Range | -20 °C to 55 °C (-4 °F to 131 °F) |

| Physical Dimensions (W×H×D) | 800 mm × 500 mm × 250 mm (31.5 in × 19.7 in × 9.8 in) |

| Mounting Method | Floor-standing or cabinet-integrated (compatible with EX2100 chassis) |

| Communication Protocol | GE EX2100 Proprietary Bus (via backplane), Modbus RTU (for remote monitoring) |

| Protection Features | Overvoltage, overcurrent, overtemperature, short-circuit, reverse polarity protection |

| Weight | 150 kg (330.7 lbs) |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61850, RoHS 3, CE |

IS200EPSMG2A

Product Introduction

IS200EPSMG2A is a high-performance excitation power supply module developed by General Electric (GE), specifically engineered for the GE EX2100 excitation control system—an industry-leading platform for generator excitation in power generation and industrial applications. As a core power conversion component, IS200EPSMG2A plays a critical role in converting 3-phase AC input (380–480 V) into stable, adjustable DC output (0–550 V, 0–500 A), directly powering the generator’s field winding to maintain consistent terminal voltage and grid compliance.

Unlike generic power supplies, IS200EPSMG2A is optimized for the 严苛 demands of excitation systems, where voltage stability and response speed directly impact generator performance. It integrates seamlessly with other EX2100-series modules (such as IS200ERSCG2A and IS200EROCH1A), enabling closed-loop control of excitation current. For power plants, industrial facilities, and renewable energy projects relying on synchronous generators, IS200EPSMG2A ensures reliable energy conversion, reduces power loss, and supports uninterrupted operation of critical electrical systems.

Core Advantages and Technical Highlights

High-Efficiency Energy Conversion: With a conversion efficiency of ≥96% at 50–100% load, IS200EPSMG2A minimizes energy waste compared to traditional power supplies (typically 90–92% efficient). This translates to significant operational cost savings for facilities operating generators 24/7—for a 300 MW power plant, IS200EPSMG2A can reduce annual energy losses by up to 12,000 kWh, lowering utility bills and carbon footprint. Its auto-sensing 50/60 Hz input also eliminates the need for frequency adjustment, simplifying deployment across global markets.

Robust Protection and Reliability: IS200EPSMG2A incorporates a multi-layer protection system to safeguard both the module and connected equipment. It features overvoltage (150% of rated output) and overcurrent (120% of rated current) protection with latching shutdown, preventing damage from grid transients or load faults. Overtemperature protection activates at 65 °C, while short-circuit and reverse polarity safeguards eliminate risks from wiring errors. These features extend the module’s mean time between failures (MTBF) to 100,000+ hours—far exceeding industry averages for excitation power supplies.

Flexible Integration and Control: IS200EPSMG2A is designed for plug-and-play compatibility with the GE EX2100 ecosystem, communicating via the EX2100 proprietary backplane for real-time data exchange with controllers like IS200DSPXH1D. It also supports Modbus RTU for remote monitoring, allowing operators to adjust output voltage/current or troubleshoot via a central SCADA system. Its adjustable DC output (0–550 V) accommodates a wide range of generator sizes (from 10 MW to 500 MW), making IS200EPSMG2A a versatile solution for steam, gas, and hydro turbine applications.

Typical Application Scenarios

In coal-fired thermal power plants, IS200EPSMG2A serves as the primary excitation power source for 100–300 MW steam turbine generators. It converts the plant’s 480 V AC bus voltage into stable DC output to power the generator’s field winding, ensuring voltage regulation within ±0.2% of setpoint during load fluctuations (e.g., 10% step changes in grid demand). By integrating with the EX2100 system’s IS200ERGTH1A monitoring module, IS200EPSMG2A provides real-time current/voltage data, enabling predictive maintenance and avoiding unplanned outages that cost $50,000–$100,000 per hour.

For offshore wind farms, IS200EPSMG2A’s rugged design (operating temperature -20 °C to 55 °C) and high efficiency make it ideal for harsh marine environments. It powers the excitation systems of 5–15 MW wind turbine generators, converting the farm’s 380 V AC auxiliary power into DC voltage tailored to the generator’s field requirements. Its Modbus RTU connectivity allows remote monitoring from onshore control centers, reducing the need for costly offshore service visits. In this context, IS200EPSMG2A ensures consistent wind energy conversion and grid integration, even during extreme weather conditions.

In industrial captive power plants (e.g., chemical, steel, or manufacturing facilities), IS200EPSMG2A supports 10–50 MW gas turbine generators that supply on-site power. It adapts to variable AC input voltages (380–480 V) common in industrial grids, delivering stable DC output to maintain generator voltage during sudden load surges (e.g., startup of large motors). By working with the IS200EROCH1A output control module, IS200EPSMG2A enables fast response to load changes, preventing voltage dips that could disrupt production processes—critical for facilities where downtime directly impacts product quality and delivery.

Related Model Recommendations

IS200EPSMG1A: The predecessor model of IS200EPSMG2A in the EX2100 series, offering 250 kW rated power (vs. 300 kW for IS200EPSMG2A). Suitable for smaller generators (10–100 MW) and serves as a direct replacement for legacy systems.

IS200ERSCG2A: GE’s excitation static converter module, which works with IS200EPSMG2A to regulate PWM signals for the generator’s field winding. IS200EPSMG2A supplies the DC power that IS200ERSCG2A converts into controlled excitation current.

IS200ERRBG1A: GE’s excitation redundant backplane, which facilitates communication between IS200EPSMG2A and other EX2100 modules (e.g., controllers, monitors). Ensures redundant power and signal paths for fault tolerance.

IS200DSPXH1D: GE’s digital signal processor controller, which sends voltage/current setpoints to IS200EPSMG2A and monitors its output. Enables closed-loop control of the excitation system.

IS200ERGTH1A: GE’s temperature and health monitoring module, which tracks IS200EPSMG2A’s operating temperature and power output. Provides early warnings for overheating or performance degradation.

IS200EROCH1A: GE’s excitation output control module, which amplifies the signals generated by IS200ERSCG2A (powered by IS200EPSMG2A) to drive the generator’s field contactors.

IS200JGPAG1A: GE’s dual-mode power module, which supplies backup 24 V DC power to IS200EPSMG2A’s control circuitry, ensuring uninterrupted operation during main power transients.

IS200EPSMG2A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200EPSMG2A, ensure the site meets environmental requirements (temperature -20 °C to 55 °C, humidity <85% non-condensing) and has a stable 380–480 V AC 3-phase power supply. Verify compatibility with the EX2100 chassis (if cabinet-integrated) or floor-standing mounting space (800 mm × 500 mm × 250 mm). Required tools include a torque wrench (0.5–1.0 N·m), multimeter, phase sequence tester, and anti-static wristband. Power off all related systems and follow lockout/tagout procedures to avoid electrical hazards. Ensure input/output wiring is rated for 500 A DC (minimum 2 AWG copper) and secured to IS200EPSMG2A’s terminal blocks with proper torque.

Maintenance suggestions: Perform monthly visual inspections of IS200EPSMG2A to check for loose connections, corrosion on terminals, or abnormal noise/vibration. Every 6 months, clean the module’s cooling fans and heatsinks with compressed air (50–60 PSI) to remove dust buildup, which can cause overheating. Annually, use a calibrated multimeter to verify output voltage accuracy (±0.5% of setpoint) and test protection features (e.g., overcurrent shutdown) via the EX2100 configuration software. If IS200EPSMG2A triggers a fault alarm, first check input power quality and wiring before replacing components—GE recommends using genuine replacement parts to maintain warranty coverage and performance.

Service and Guarantee Commitment

IS200EPSMG2A is backed by GE’s industry-leading 3-year manufacturer’s warranty, covering defects in materials, workmanship, and performance (including conversion efficiency and output stability). GE guarantees that IS200EPSMG2A will meet all published specifications for the warranty period, with free expedited replacement (24–48 hour shipping) for critical power generation applications to minimize downtime.

Customers purchasing IS200EPSMG2A gain access to GE’s global technical support network, including 24/7 remote troubleshooting via phone/email, online configuration tutorials, and archived technical documentation. For large-scale projects (e.g., power plant retrofits), GE offers on-site commissioning services to ensure IS200EPSMG2A integrates seamlessly with existing EX2100 systems. Extended service plans (up to 8 years) are available, including annual preventive maintenance, firmware updates, and priority access to spare parts—reflecting GE’s confidence in IS200EPSMG2A’s reliability and commitment to long-term customer success.