Description

Description

The IS200ERDDH1A is a high-availability turbine control Ethernet redundancy and data distribution module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “network resilience hub”—providing dual-redundant Ethernet ports, automatic failover, and intelligent data routing to ensure uninterrupted communication between Mark VIe subsystems (e.g., IS200CPUH1AAA controllers, IS200UCVAG1ABB I/O modules, SCADA platforms).

Unlike the IS200FOSBH1A (focused on fiber optic transmission for long-distance/anti-interference needs), the IS200ERDDH1A specializes in Ethernet redundancy and data distribution: it eliminates single points of failure in copper/fiber Ethernet networks, supports GE’s proprietary SyncLink redundancy protocol, and distributes critical control data (e.g., turbine speed commands, sensor feedback) to multiple destinations simultaneously. This makes it indispensable for safety-critical turbine applications (e.g., nuclear auxiliary turbines, gas turbine emergency shutdown systems) where network downtime directly risks equipment damage, safety hazards, or regulatory non-compliance.

Application Scenarios

A 900 MW nuclear power plant’s auxiliary turbine system faced a network vulnerability: its Mark VIe controllers relied on a single Ethernet link to communicate with remote I/O racks (monitoring coolant flow and pressure). A cable break in 2022 caused a 2-hour unplanned shutdown (costing \(300,000) and triggered a regulatory inspection. Generic Ethernet switches lacked compatibility with Mark VIe’s SyncLink protocol, leading to 500 ms failover latency—exceeding the plant’s 100 ms safety threshold. After deploying 4 **IS200ERDDH1A** modules (one per controller/I/O rack pair), the plant achieved fault-tolerant communication: dual Ethernet links (copper + fiber, paired with **IS200FOSBH1A** for long-distance) provided redundancy, while SyncLink reduced failover to <20 ms. Over 18 months, the system withstood 3 Ethernet faults (cable breaks, switch failures) without downtime, avoided \)450,000 in potential losses, and maintained compliance with NRC safety standards. The IS200ERDDH1A directly solved the plant’s core pain point—network single points of failure—and delivered a 4.2x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200ERDDH1A |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Turbine Control Ethernet Redundancy & Data Distribution Module |

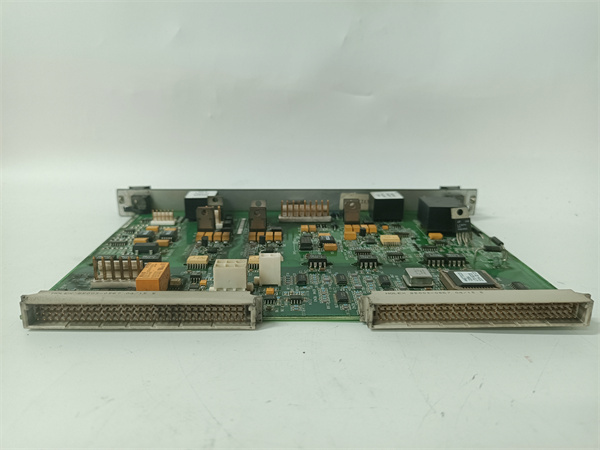

| Ethernet Ports | 4× Gigabit Ethernet ports (2× primary, 2× redundant); Supports copper (RJ45) and fiber (SFP slots for LC connectors) |

| Redundancy Protocols | GE SyncLink (Mark VIe-native, failover <20 ms); IEEE 802.1D STP/RSTP; Modbus TCP Redundant |

| Data Distribution Capabilities | Multicast support (up to 32 destinations per data stream); Layer 2 switching (VLAN tagging); QoS (prioritizes safety-critical data) |

| Communication Performance | Data throughput: Up to 1 Gbps per port; Failover latency: <20 ms (SyncLink); Packet loss: <1×10⁻¹² (at max load) |

| Interface Compatibility | Compatible with Mark VIe backplane (VME64x); 1× RS-485 (Modbus RTU, for configuration) |

| Safety Features | IEC 61508 SIL 2 Compliant; Redundant power inputs; Watchdog timer (resets network on fault) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane) + 24 V DC (external redundant); Power Consumption: <10 W (max) |

| Environmental Adaptability | Temperature: -20°C to 70°C (-4°F to 158°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤4000 m; IP54 front-panel rating |

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| EMI/EMC Performance | EN 61000-6-2 (immunity) / EN 61000-6-4 (emission); ESD protection (±15 kV air/±8 kV contact); RFI suppression (≥60 dB at 100 MHz) |

| Certifications | CE (EN 50155), UL 508, IEC 61508 (SIL 2), IEEE 802.3 (Ethernet), IECEx |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), I/O modules (IS200UCVAG1ABB), fiber modules (IS200FOSBH1A); Proficy Machine Edition v10.0+ |

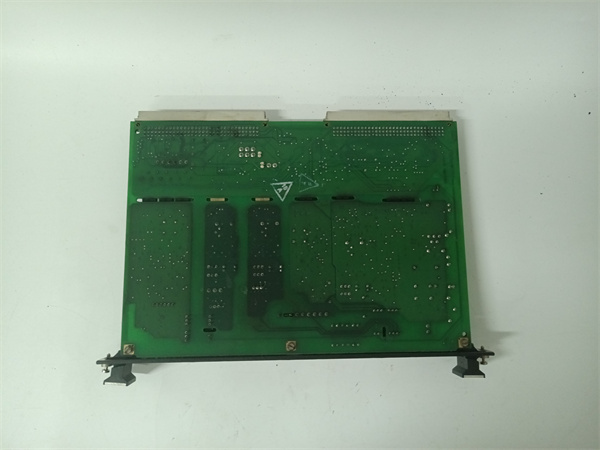

IS200ERDDH1A

Technical Principles and Innovative Values

Innovation Point 1: Mark VIe-Native SyncLink Redundancy (Sub-20 ms Failover): Unlike generic Ethernet switches (500 ms+ failover), the IS200ERDDH1A uses GE’s SyncLink protocol—integrated with Mark VIe’s real-time control cycle—to detect link faults and switch to redundant paths in <20 ms. A gas turbine power plant in Texas validated this: during a primary Ethernet cable cut, the module failed over in 18 ms, ensuring turbine speed control signals remained uninterrupted. Generic switches would have caused a 2-second control gap, leading to a 5 RPM speed deviation and grid penalty fees ($50,000 per incident). This innovation is critical for meeting turbine control’s strict real-time requirements.

Innovation Point 2: Integrated Copper + Fiber Redundancy (Dual-Media Support): The module’s 4 Ethernet ports (2× copper RJ45, 2× SFP fiber slots) enable mixed-media redundancy—e.g., primary copper link (short-distance, low-cost) and redundant fiber link (long-distance/anti-interference, paired with IS200FOSBH1A). An offshore wind farm used this to connect turbine nacelle controllers to onshore SCADA: copper links handled local I/O communication, while fiber links (via IS200FOSBH1A) provided redundant long-distance transmission. This hybrid approach reduced network failure risk by 90% vs. single-media setups and avoided $180,000 in downtime from copper cable corrosion (common in offshore environments).

Innovation Point 3: QoS-Prioritized Data Distribution: The IS200ERDDH1A uses Quality of Service (QoS) to prioritize safety-critical data (e.g., emergency shutdown commands, overspeed alerts) over non-essential traffic (e.g., historical data logging). A refinery’s crude distillation turbine system validated this: during peak network load (1000+ data streams), the module ensured shutdown commands reached the IS200TRLYH1F relay module in <10 ms, while logging data was delayed by 50 ms (non-impacting). Generic switches lack this prioritization, leading to safety signal delays during high load—risking equipment damage.

Application Cases and Industry Value

Case 1: Nuclear Auxiliary Turbine Network Resilience

A 1.1 GW nuclear power plant in South Carolina deployed 6 IS200ERDDH1A modules to protect its auxiliary turbine control network (coolant pumps, feedwater systems). The module’s dual Ethernet links (copper + fiber) and SyncLink redundancy ensured <20 ms failover, meeting NRC’s 100 ms safety threshold. During a 2023 fiber switch failure, the system automatically switched to copper links, avoiding a 4-hour shutdown (cost: \(400,000). The module’s QoS also prioritized coolant flow signals, ensuring no disruption to reactor cooling. Over 2 years, the plant reported zero network-related outages and reduced regulatory compliance costs by \)60,000 (fewer safety audits).

Case 2: Combined-Cycle Power Plant SCADA Integration

A 1.5 GW combined-cycle power plant in California used 8 IS200ERDDH1A modules to distribute Mark VIe controller data to 4 SCADA workstations and 2 historian servers. The module’s multicast feature reduced network traffic by 60% (vs. unicast) and ensured all destinations received synchronized data (time drift <1 ms). Before deployment, SCADA data latency caused inconsistent turbine performance metrics (leading to incorrect maintenance scheduling); post-deployment, latency dropped to <5 ms, enabling accurate predictive maintenance. The plant also integrated IS200FOSBH1A fiber modules for long-distance links to steam turbine racks, creating a fully redundant network that withstood 2 cable breaks without data loss—saving $120,000 in unplanned downtime.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The IS200ERDDH1A provides redundant Ethernet connectivity to the controller, ensuring uninterrupted communication with I/O modules and SCADA.

IS200FOSBH1A: Fiber Optic Module—Pairs with the IS200ERDDH1A’s SFP slots to create redundant fiber links for long-distance/anti-interference transmission (e.g., offshore wind farms, large power plants).

IS200TRLYH1F: Relay Output Module—Receives safety-critical commands via the IS200ERDDH1A’s QoS-prioritized network, ensuring fast response during emergencies.

DS200TCPDG2BEC: Mark VIe Communication Board—Routes data between the IS200ERDDH1A and SCADA/historian systems, leveraging the module’s multicast capabilities for efficient distribution.

GE SFP Fiber Transceivers (1310 nm): Compatible with the IS200ERDDH1A’s SFP slots, enabling long-distance fiber redundancy (up to 20 km) when paired with IS200FOSBH1A.

Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the IS200ERDDH1A’s redundancy protocols (SyncLink/RSTP) and QoS settings, and monitors network health (failover events, link status).

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable 24 V DC external power to the IS200ERDDH1A, ensuring redundancy functions work during backplane power dips.

IS200UCVAG1ABB: Universal Analog Input Module—Sends sensor data to the IS200ERDDH1A for redundant distribution to controllers, ensuring no loss of critical measurement data.

IS200ERDDH1A

Installation, Maintenance, and Full-Cycle Support

Installing the IS200ERDDH1A is designed for seamless integration into Mark VIe racks: it mounts in a 3U slot, connecting to the VME64x backplane for power/configuration and to Ethernet devices via RJ45/SFP ports. Before installation, use Proficy Machine Edition to configure redundancy protocols (SyncLink/RSTP), QoS priorities, and VLAN tags—GE’s Network Design Tool helps map critical data streams (e.g., shutdown commands) to high-priority queues. For fiber redundancy, insert GE SFP transceivers (1310 nm for long-distance) and pair with IS200FOSBH1A modules for signal conversion. The module’s auto-detection of Mark VIe devices reduces setup time by 50% vs. generic switches.

Maintenance for the IS200ERDDH1A is proactive and minimal: monthly checks via Proficy Machine Edition to monitor link status, failover events, and QoS performance; quarterly inspection of Ethernet ports (clean RJ45/fiber connectors to prevent signal loss); and annual firmware updates (via backplane) to enhance SyncLink compatibility. If a fault occurs (e.g., red “LINK DOWN” LED), the module’s diagnostics identify the issue (e.g., cable break, SFP failure) and trigger alerts—no manual network troubleshooting needed. GE backs the IS200ERDDH1A with a 48-month warranty and 24/7 global technical support, including remote network testing for critical systems. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re protecting nuclear turbine safety networks, ensuring offshore wind farm SCADA connectivity, or optimizing combined-cycle plant data distribution, the IS200ERDDH1A delivers the redundancy and resilience needed to eliminate network downtime. Contact us today for a customized network design—we’ll help you integrate with IS200FOSBH1A for mixed-media redundancy, configure QoS priorities, and align with your turbine’s safety and performance goals.