Description

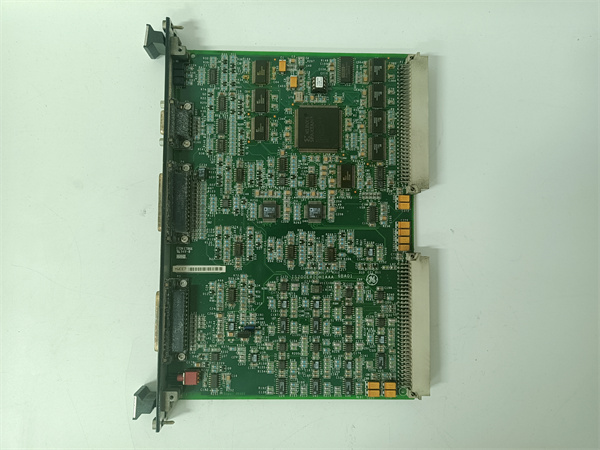

Product Description: GE IS200ERIOH1A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200ERIOH1A |

| Manufacturer | General Electric (GE) |

| Product category | Excitation Regulator I/O Module (EX2100 Excitation Control Series) |

| Core function | Digital and analog signal processing; field device interface; system integration |

| Input channels | 8 AI (0–10 V or 4–20 mA); 4 RTD inputs (PT100) |

| Output channels | 4 AO (0–10 V or 4–20 mA); 8 DO (24 V DC, 2 A) |

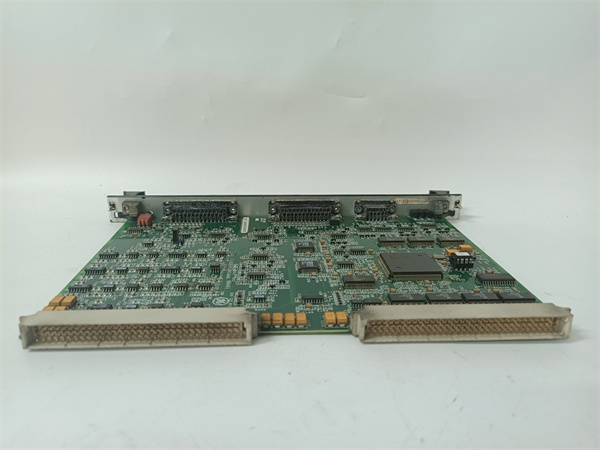

| Communication interface | GE EX2100 backplane; Modbus RTU (optional) |

| Power requirement | 24 V DC (redundant), 22–26 V DC; 8 W max power consumption |

| Operating temperature | -30 °C to 70 °C (-22 °F to 158 °F) |

| Physical dimensions | 160 mm × 108 mm × 25 mm (6.30 in × 4.25 in × 0.98 in) |

| Mounting method | DIN rail mount; EX2100 chassis slot compatible |

| Protection features | Channel isolation (500 Vrms); overvoltage protection; ESD immunity |

| Diagnostic capabilities | Channel fault detection; open/short circuit detection; module health monitoring |

| Compliance standards | UL 508, IEC 61010-1, IEC 61326-1, RoHS 3, CE |

| Weight | 230 g (8.11 oz) |

IS200ERIOH1A

Product Introduction

IS200ERIOH1A is a high-performance excitation regulator I/O module developed by General Electric (GE) for the EX2100 excitation control system. This module serves as the critical interface between the excitation control system and field devices, providing comprehensive signal processing capabilities for both analog and digital signals.

Designed specifically for power generation applications, IS200ERIOH1A enables precise monitoring and control of generator excitation parameters. It seamlessly integrates with other EX2100 components such as IS200ERSCG2A (static converter), IS200EROCH1A (output control), and IS200EPSMG2A (power supply), forming a complete excitation control solution. The module’s rugged design and comprehensive diagnostic capabilities make it ideal for harsh industrial environments found in power plants and industrial facilities.

Core Advantages and Technical Highlights

Comprehensive I/O Capabilities: IS200ERIOH1A offers a versatile combination of analog and digital I/O channels, including 8 AI, 4 RTD, 4 AO, and 8 DO channels. This comprehensive signal processing capability eliminates the need for multiple specialized modules, reducing system complexity and cost.

Enhanced System Diagnostics: The module features advanced diagnostic capabilities including channel fault detection, open/short circuit detection, and comprehensive module health monitoring. These diagnostics provide valuable information for preventive maintenance and troubleshooting, reducing downtime and improving system reliability.

Robust Industrial Design: With an operating temperature range of -30°C to 70°C and comprehensive ESD protection, IS200ERIOH1A delivers reliable performance in harsh power generation environments. Its conformal coating provides additional protection against moisture, dust, and chemical contaminants.

Flexible Integration: Designed specifically for the EX2100 ecosystem, IS200ERIOH1A connects seamlessly with other system components through the standard backplane interface. It also supports Modbus RTU for integration with external monitoring and control systems, providing maximum flexibility in system design.

Typical Application Scenarios

In combined-cycle power plants, IS200ERIOH1A serves as the primary interface between the excitation control system and various field devices. It monitors critical parameters such as generator terminal voltage, field current, and various temperature measurements while providing control signals to actuators and other control devices. This comprehensive monitoring capability enables operators to maintain optimal generator performance and respond quickly to changing grid conditions.

For hydroelectric facilities, IS200ERIOH1A provides essential I/O functionality in often challenging environments. It interfaces with water flow sensors, pressure transducers, and temperature sensors throughout the facility, providing valuable data to the excitation control system. This information is used to optimize generator performance based on changing water conditions and grid requirements.

In industrial captive power plants, IS200ERIOH1A plays a crucial role in integrating the excitation system with the plant’s overall control infrastructure. It connects with various process sensors and control devices, enabling coordinated operation of the generator with other plant equipment. This integration is essential for maintaining stable power quality during industrial load fluctuations and ensuring reliable operation of critical production processes.

Related Model Recommendations

IS200ERIOH2A — Advanced version of IS200ERIOH1A with expanded I/O capabilities and enhanced communication options

IS200ERSCG2A — Static converter module that receives control signals from IS200ERIOH1A

IS200EROCH1A — Output control module that can be monitored and controlled via IS200ERIOH1A

IS200EPSMG2A — Excitation power supply module whose status can be monitored by IS200ERIOH1A

IS200ERRBG1A — Redundant backplane that facilitates communication between IS200ERIOH1A and other EX2100 modules

IS200DSPXH1D — Digital signal processor controller that coordinates with IS200ERIOH1A for system-wide control

IS200ERGTH1A — Temperature monitoring module that can complement IS200ERIOH1A‘s RTD inputs

IS200EPDMG1B — Power distribution module that provides 24 V DC power to IS200ERIOH1A

IS200ERIOH1A

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing IS200ERIOH1A, verify compatibility with the target EX2100 system configuration. Ensure the installation environment meets the specified temperature (-30°C to 70°C) and humidity requirements. Use an anti-static wristband when handling the module to prevent ESD damage. Required tools include a Phillips screwdriver, torque wrench (0.2–0.4 N·m), and multimeter. Mount the module on a standard DIN rail or in the designated EX2100 chassis slot, ensuring proper alignment with the backplane connector.

Maintenance Suggestions: Perform quarterly visual inspections of IS200ERIOH1A to check for loose connections, corrosion, or dust accumulation. Clean the module with compressed air as needed, taking care not to damage any components. Periodically verify calibration of analog channels and test digital outputs to ensure proper operation. If a fault is detected, first check the field wiring and power supply before considering module replacement. GE recommends firmware updates whenever new versions become available to ensure optimal performance and security. Always use genuine GE replacement parts to maintain system integrity and warranty coverage.

Service and Guarantee Commitment

IS200ERIOH1A is backed by GE’s comprehensive 3-year warranty, covering defects in materials, workmanship, and performance under normal operating conditions. GE guarantees that IS200ERIOH1A will meet all published specifications when properly installed and maintained according to GE guidelines.

Customers receive access to GE’s global technical support network, including 24/7 phone and email assistance from excitation system specialists. GE provides detailed installation manuals, configuration guides, and online training resources to ensure successful implementation of IS200ERIOH1A. For mission-critical applications, extended warranty and service contracts are available, offering priority technical support, accelerated replacement services, and preventive maintenance programs tailored to specific operational requirements.