Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

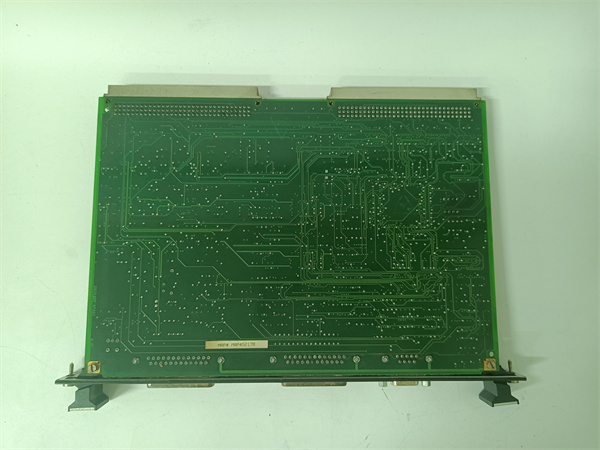

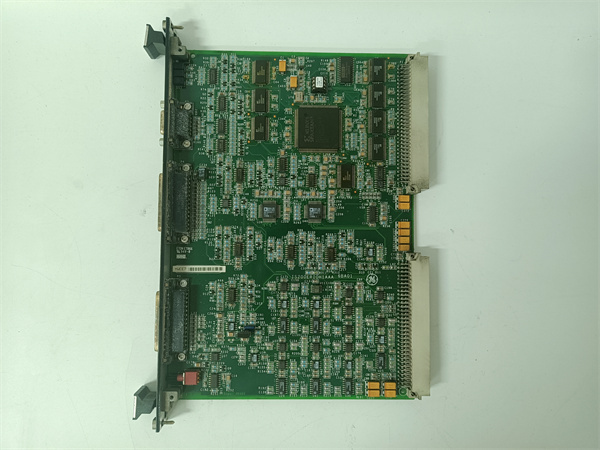

| Product model | IS200ERIOH1A |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Division) |

| Product category | Remote I/O Communication Module (for Ovation DCS Distributed I/O Integration) |

| Communication protocol | Ovation Remote I/O Protocol (ORIO); Redundant communication links (A/B paths) |

| Data transfer rate | 100 Mbps (full-duplex, dedicated for remote I/O data) |

| Maximum communication distance | Up to 10 km (6.2 miles) with single-mode fiber; Up to 1 km (0.6 miles) with multi-mode fiber |

| Supported remote I/O racks | Compatible with Ovation IS200-series remote I/O racks (max 32 racks per module) |

| I/O signal support | Transparent to analog/digital signals (4-20 mA, 0-10 V, RTD, thermocouple, dry contact) |

| Operating temperature range | 0 °C to 60 °C (32 °F to 140 °F); -40 °C to 70 °C (storage) |

| Physical dimensions | 165 mm (W) × 102 mm (H) × 229 mm (D) (6.50 in × 4.02 in × 9.02 in) |

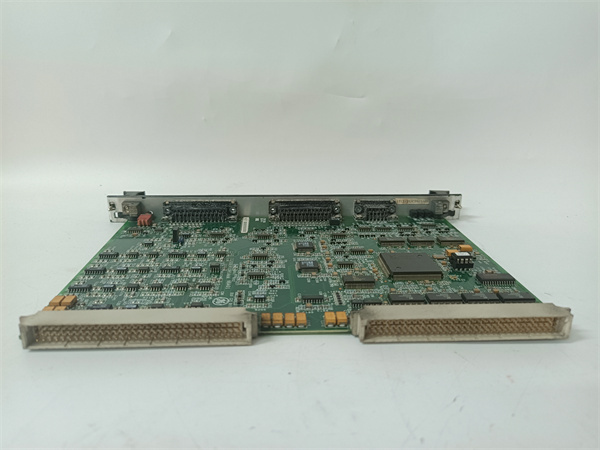

| Installation method | Ovation 3U I/O chassis mounting (compatible with IS200-series local I/O racks) |

| Power supply requirements | 5 V DC (±5%); 1.3 A maximum current draw; Powered via Ovation chassis backplane |

| Protection features | Fiber optic port surge protection (15 kV ESD); Redundant link auto-switchover; Over-temperature protection (70 °C shutdown) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1; IEC 60825-1 (laser safety for fiber ports) |

| MTBF (Mean Time Between Failures) | 2,300,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Diagnostic capabilities | Redundant link status monitoring; Remote rack connection loss alerts; Data transmission error logging; Power fault detection |

| Fiber optic ports | 2 x SC-type single-mode/multi-mode ports (for redundant A/B links) |

| Weight | 475 g (1.05 lb) |

IS200ERIOH1A

Product Introduction

The IS200ERIOH1A is a dedicated remote I/O communication module from Emerson’s Ovation distributed control system (DCS) portfolio, designed to serve as the “data bridge” between Ovation’s local control system and geographically dispersed remote I/O racks. As a core component for distributed automation, the IS200ERIOH1A uses Emerson’s proprietary Ovation Remote I/O Protocol (ORIO) to transmit real-time I/O data—including analog signals (4-20 mA, RTDs) and digital signals (dry contacts)—between the local Ovation controller and remote racks, eliminating the need for costly, large-gauge wiring to distant field devices.

This module solves a key challenge in large facilities: for example, in a coal-fired power plant with a boiler house 5 km from the turbine hall, the IS200ERIOH1A can connect the local Ovation DCS to a remote I/O rack near the boiler, transmitting temperature, pressure, and valve status data via fiber optic cables. Its redundant A/B communication links ensure no single point of failure disrupts data flow, while its 100 Mbps full-duplex transfer rate guarantees low-latency (≤10 ms) data transmission—critical for time-sensitive control tasks. The IS200ERIOH1A’s fiber optic ports also provide immunity to electromagnetic interference (EMI), making it ideal for industrial environments with heavy machinery or high-voltage equipment.

Core Advantages and Technical Highlights

Long-Distance Fiber Optic Communication for Distributed Facilities: The IS200ERIOH1A supports fiber optic transmission up to 10 km (single-mode) or 1 km (multi-mode)—far exceeding the range of copper-based remote I/O solutions (typically ≤100 m). This capability eliminates the need for expensive intermediate repeaters or long runs of copper cable, reducing installation costs by up to 50% in large facilities like refineries or municipal water treatment plants with scattered pump stations. For example, a water utility can connect a remote I/O rack at a reservoir 8 km from the main control center via a single IS200ERIOH1A module, avoiding the cost of trenching for copper cables.

Redundant A/B Links for Uninterrupted Data Flow: Unlike basic remote I/O modules with single communication paths, the IS200ERIOH1A features redundant A/B fiber optic links with auto-switchover (≤5 ms). If the active A link fails (e.g., due to a fiber break), the module immediately switches to the B link without disrupting data transmission. This redundancy is critical for mission-critical applications—such as nuclear power plant safety systems—where a loss of I/O data could trigger unnecessary emergency shutdowns costing hundreds of thousands in lost production.

EMI Immunity & Surge Protection for Harsh Environments: The IS200ERIOH1A’s fiber optic ports are immune to EMI and radio frequency interference (RFI)—common in industrial settings with VFDs, motors, or high-voltage lines. Unlike copper cables, which can pick up noise and distort signals, fiber optics transmit data via light, ensuring signal integrity even near large transformers or welding equipment. Additionally, the module’s 15 kV ESD protection safeguards fiber ports from static discharge during maintenance, while over-temperature protection (70 °C shutdown) prevents component damage in hot environments like boiler rooms.

Transparent I/O Signal Support & High Scalability: The IS200ERIOH1A is “signal-transparent,” meaning it works with all Ovation-compatible I/O signals (analog, digital, RTD, thermocouple) without requiring signal conversion. This eliminates the need for specialized modules for different signal types, simplifying system design. The module also supports up to 32 remote I/O racks per unit, enabling scalability for growing facilities—for example, a chemical plant can add 10 new remote racks (for additional sensors) without replacing the IS200ERIOH1A, reducing capital expenditure.

Typical Application Scenarios

In combined-cycle power plants, the IS200ERIOH1A is used to connect the local Ovation DCS (in the control room) to remote I/O racks near the gas turbine, steam turbine, and HRSG (heat recovery steam generator). For instance, a remote rack near the HRSG collects data from 4-20 mA steam flow sensors and K-type thermocouples, then transmits this data to the local DCS via the IS200ERIOH1A (over a 3 km single-mode fiber link). The module’s low latency (≤10 ms) ensures the Ovation controller receives real-time data to adjust fuel flow and steam pressure, optimizing combined-cycle efficiency by 1-2%. Its redundant links also prevent data loss during fiber maintenance or unexpected breaks.

Oil refineries rely on the IS200ERIOH1A to integrate remote I/O racks in hazardous areas (e.g., distillation columns, storage tanks) with the central Ovation DCS. The module’s fiber optic communication eliminates the risk of sparking from copper cables (critical for Class I, Division 1 hazardous locations), while its EMI immunity ensures reliable data transmission near high-voltage pumps and compressors. For example, a remote I/O rack near a crude oil storage tank sends level and temperature data to the central DCS via the IS200ERIOH1A, enabling operators to monitor tank conditions without placing sensitive electronics in the hazardous area.

Municipal wastewater treatment plants use the IS200ERIOH1A to connect remote I/O racks at multiple lift stations (spread across a city) to the main Ovation DCS. Each lift station’s remote rack collects data from 4-20 mA level sensors and digital pump status signals, then transmits this data to the central DCS via a 5 km multi-mode fiber link. The IS200ERIOH1A’s scalability allows the plant to add 15+ lift stations to the system without upgrading hardware, while its diagnostic features alert operators to a failed fiber link before it causes a lift station overflow—avoiding environmental fines and service disruptions.

Related Model Recommendations

IS200ERIOR1A: A complementary remote I/O rack controller that pairs with the IS200ERIOH1A—the IS200ERIOH1A (local module) communicates with the IS200ERIOR1A (remote rack controller) to transmit I/O data between the local DCS and remote rack.

1C31234G01: Ovation’s main controller that works with the IS200ERIOH1A—the controller processes I/O data received from the IS200ERIOH1A (from remote racks) and executes control logic (e.g., adjusting pump speed based on remote level data).

IS200ISBAH1A: Emerson’s analog input module that integrates with the IS200ERIOH1A—analog data (e.g., RTD temperature) collected by IS200ISBAH1A in a remote rack is transmitted to the local DCS via the IS200ERIOH1A.

IS200SDIIH1A: High-density digital input module compatible with the IS200ERIOH1A—digital signals (e.g., valve position) from IS200SDIIH1A in a remote rack are sent to the local DCS via the IS200ERIOH1A.

IS200SSCAH2A: Ovation’s system synchronization module that works with the IS200ERIOH1A—it synchronizes the clock of remote I/O racks (via the IS200ERIOH1A) with the local DCS, ensuring time-aligned I/O data for accurate process correlation.

IS200ERIOH2A: An upgraded variant of the IS200ERIOH1A with 1 Gbps data transfer rate (vs. 100 Mbps) and support for up to 64 remote racks—suited for ultra-large facilities (e.g., multi-site petrochemical complexes) with high I/O traffic.

Emerson Ovation Remote I/O Rack (IS200RACK): A dedicated remote I/O chassis that pairs with the IS200ERIOH1A—it houses I/O modules (e.g., IS200ISBAH1A, IS200SDIIH1A) and communicates with the local DCS via the IS200ERIOH1A.

IS200SCNVG1A: Ovation’s network gateway module that complements the IS200ERIOH1A—it translates remote I/O data (from the IS200ERIOH1A) into Modbus TCP/IP for transmission to external SCADA systems, enabling multi-platform monitoring.

IS200ERIOH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200ERIOH1A, power off the Ovation 3U local I/O chassis and verify it is grounded (minimum 4 mm² ground wire) to prevent electrical shock. Confirm the chassis slot is compatible with IS200-series modules and the environment meets the module’s operating range (0-60 °C, 10-90% non-condensing humidity). Required tools include a torque screwdriver (0.5-0.8 N·m for mounting), fiber optic cable stripper/crimper (for SC connectors), and an optical power meter (to verify fiber link integrity). Use single-mode (for >1 km) or multi-mode (for ≤1 km) fiber optic cable with SC connectors; label A/B links clearly (e.g., “ERIO A-Link: Turbine Hall Remote Rack”) to avoid misconnection. Ensure fiber cables are routed away from high-voltage lines to prevent physical damage.

Maintenance suggestions: For daily maintenance of the IS200ERIOH1A, check the LED status lights (power: green; A-link: solid green = active, flashing green = standby; B-link: solid amber = active, flashing amber = standby; fault: red) during shift handovers—red LEDs indicate critical issues (e.g., fiber break, over-temperature). Every 3 months, clean SC fiber connectors with lint-free wipes and isopropyl alcohol to remove dust (dirty connectors cause signal loss); use an optical power meter to verify signal strength (should be ≥-15 dBm). Test redundant link switchover quarterly by disconnecting the active A-link—confirm the module switches to B-link within 5 ms (no data loss). If a link fails, use an optical time-domain reflectometer (OTDR) to locate fiber breaks before replacing cables or the IS200ERIOH1A. Use only Emerson-approved spare modules and fiber optic components to ensure compatibility.

Service and Guarantee Commitment

The IS200ERIOH1A comes with a 2-year standard warranty from Emerson Automation Solutions, covering defects in materials, workmanship, and performance under normal industrial use. If the module fails within this period (e.g., fiber port malfunction, redundant link failure), Emerson will repair or replace it free of charge, with expedited shipping (24-48 hours for regional warehouses) to minimize downtime—critical for facilities relying on remote I/O data for process control.

Emerson offers 24/7 global technical support for the IS200ERIOH1A: certified Ovation engineers specialize in remote I/O troubleshooting and can assist with fiber link configuration, redundancy setup, and signal integrity testing via phone, email, or remote access (Emerson Remote Support Portal). Support includes guidance on fiber optic cable selection (single-mode vs. multi-mode) and help with diagnosing link failures (e.g., using OTDR data). Customers gain access to the Ovation Knowledge Base, which includes the IS200ERIOH1A’s technical manual, fiber installation guides, firmware updates, and application notes (e.g., “Designing Redundant Remote I/O Networks with Ovation DCS”).

For mission-critical applications (e.g., nuclear power plant remote safety systems), Emerson provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site fiber link testing, module calibration, and redundancy validation to ensure the IS200ERIOH1A meets strict industry standards (e.g., NERC CIP, IEC 61508). This commitment reflects Emerson’s confidence in the module’s reliability and its dedication to helping customers maintain seamless distributed I/O integration.