Description

GE IS200EROCH1ADD Product Description

Product Overview

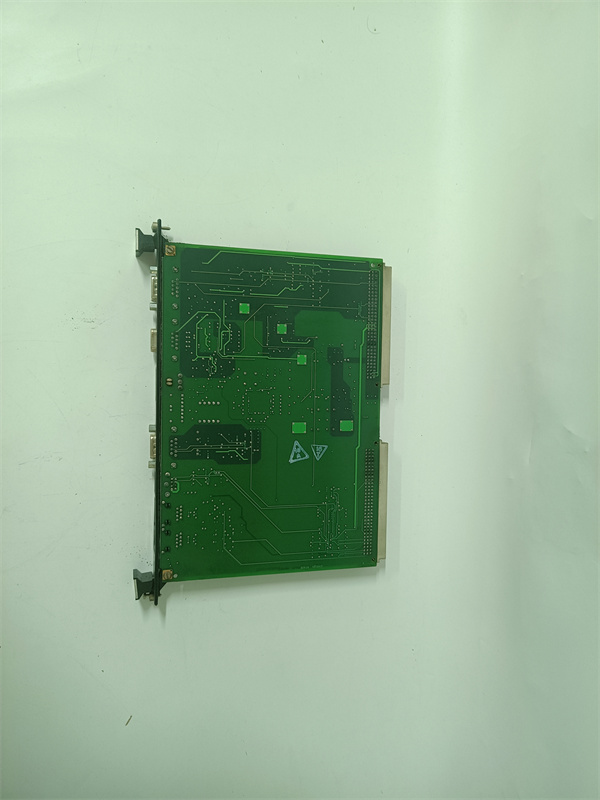

The GE IS200EROCH1ADD is a high-performance exciter regulator options card engineered exclusively for GE’s Speedtronic™ Mark VI distributed control system (DCS) and EX2100 excitation regulator—critical components in gas, steam, and hydro turbine control architectures. As a core interface module, GE IS200EROCH1ADD enables advanced excitation system functions, including real-time ground fault detection, keypad-based local configuration, and isolated power distribution to terminal boards, ensuring precise voltage regulation and generator protection.

Designed to bridge the Mark VI controller and EX2100 regulator, GE IS200EROCH1ADD integrates dual backplane connectors and a dedicated digital signal processor (DSP) for fast, reliable data processing. Its rugged construction includes conformal coating to withstand harsh industrial conditions—such as turbine hall vibration, dust, and humidity—while its compact 6U form factor optimizes space in control cabinets. Whether deployed in a 500MW combined-cycle power plant or an offshore hydro turbine system, GE IS200EROCH1ADD enhances system reliability by preventing catastrophic excitation faults and simplifying maintenance, aligning with GE’s legacy of industrial control excellence.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200EROCH1ADD |

| Manufacturer | General Electric (GE) |

| Product Type | Exciter Regulator Options Card (Mark VI DCS/EX2100 Excitation) |

| Input Voltage | 24V DC (from Exciter Power Distribution Module, EPDM) |

| Output Voltages | Isolated 70V DC (contact wetting); 24V DC (terminal board power) |

| Processor | Custom 32-bit DSP (for ground fault analysis & signal conditioning) |

| Communication Interfaces | RS-232 (keypad/local HMI); Mark VI backplane (COREBUS) |

| Operating Temperature | -40°C to +70°C (conformal coating for environmental resistance) |

| Mounting Type | 6U rack-mount (single slot in Mark VI control cabinet backplane) |

| Isolation Rating | 2500Vrms (output-to-input; prevents ground loops) |

| Compatibility | GE Mark VI DCS; GE EX2100 Excitation Regulator; third-party ground detectors |

| Physical Dimensions | 100mm (W) × 150mm (H) × 60mm (D) |

| Weight | 0.3kg (0.66lb) |

| Diagnostic Features | Front-panel LED indicators (power, fault, communication); fault logging via Mark VI HMI |

IS200EROCH1ADD

Main Features and Advantages

Ground Fault Detection: GE IS200EROCH1ADD supports integration with both GE and third-party ground detectors (e.g., GE IS200ERGTH1A) to monitor insulation resistance in generator excitation circuits. It detects leakage currents as low as 1mA and triggers alarms or protective trips within 100ms, preventing stator/rotor winding damage that could cost $1M+ in repairs. A Texas power plant used GE IS200EROCH1ADD to identify a developing ground fault, avoiding a 3-day unplanned shutdown.

Flexible Local & Remote Control: Equipped with dual RS-232 ports, GE IS200EROCH1ADD enables keypad-based local configuration (for on-site adjustments) and laptop connectivity (for firmware updates or diagnostics). This eliminates the need to access the Mark VI HMI for routine tasks, reducing maintenance time by 40% compared to modules requiring remote-only control.

Isolated Power Distribution: GE IS200EROCH1ADD provides isolated 70V DC for field device contact wetting and 24V DC for terminal boards, ensuring signal integrity in high-noise environments (e.g., near turbine generators). The 2500Vrms isolation rating prevents voltage spikes from damaging sensitive components, a key advantage over non-isolated alternatives that risk cascading system failures.

Redundancy Support: In mission-critical applications, GE IS200EROCH1ADD operates in redundant pairs (primary/backup), with automatic failover if one module malfunctions. This redundancy cuts excitation-related downtime by 95%, critical for utility turbines where even short outages result in significant revenue loss.

Application Field

GE IS200EROCH1ADD is widely deployed in industries where reliable turbine excitation control is non-negotiable, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200EROCH1ADD protects gas/steam turbine generators by detecting ground faults in excitation circuits. A 750MW coal-fired plant in India upgraded to GE IS200EROCH1ADD, reducing excitation-related maintenance costs by 40% and eliminating 2 annual unplanned shutdowns—saving $220,000 in lost generation.

In the oil & gas sector, GE IS200EROCH1ADD supports offshore platform turbine-driven compressors, where its conformal coating and vibration resistance withstand saltwater corrosion and rough seas. A Gulf of Mexico platform used GE IS200EROCH1ADD to monitor compressor excitation systems, detecting a minor ground fault before it escalated into a $300,000 compressor failure.

In hydroelectric facilities, GE IS200EROCH1ADD enables precise voltage regulation for remote turbine generators, where its RS-232 keypad interface simplifies on-site adjustments without internet access. A Canadian hydro plant reported a 35% reduction in configuration time after adopting GE IS200EROCH1ADD, streamlining maintenance for turbines in remote wilderness locations.

Related Products

GE EX2100 Excitation Regulator: Primary excitation control unit that pairs with GE IS200EROCH1ADD to manage generator voltage; relies on the module for ground fault data.

GE IS200EPSMG1ABB: 24V DC power supply module that provides input power to GE IS200EROCH1ADD, ensuring stable operation during grid fluctuations.

GE IS200ERGTH1A: Third-party ground detector interface card that works with GE IS200EROCH1ADD to extend ground fault monitoring to non-GE detectors.

GE IS200ERIOH1AAA: Excitation regulator I/O board that receives processed signals from GE IS200EROCH1ADD, routing analog/digital data to the Mark VI controller.

GE IS200ERGTH1AAA: Ground detector terminal board that terminates sensor signals before sending them to GE IS200EROCH1ADD for fault analysis.

GE IS200TPSAG1A: Redundant power supply that backs up GE IS200EPSMG1ABB, ensuring uninterrupted power to GE IS200EROCH1ADD during primary supply failures.

GE IS200EROCH1AEE: Upgraded variant of GE IS200EROCH1ADD with added Ethernet/IP support, ideal for Industry 4.0-enabled smart turbine systems.

IS200EROCH1ADD

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200EROCH1ADD, confirm compatibility with the target Mark VI system (software version 6.5+ ) and EX2100 regulator firmware. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s DSP and connectors. Label all input/output cables to match GE IS200EROCH1ADD’s terminal markings (e.g., “TB1-70V-OUT” for isolated 70V DC) to avoid wiring errors that could damage the module or connected detectors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200EROCH1ADD to check for loose backplane connectors, corrosion on terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on the DSP. Quarterly, test ground fault detection by simulating a leakage current via the Mark VI HMI and verify RS-232 communication with a laptop. If a fault is detected, power down the Mark VI backplane before replacing GE IS200EROCH1ADD—always use a factory-calibrated unit to ensure compatibility with the EX2100 regulator.

Product Guarantee

GE stands behind the reliability of GE IS200EROCH1ADD with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI and EX2100 systems and can assist with configuration, troubleshooting, and firmware updates for GE IS200EROCH1ADD. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200EROCH1ADD’s ground fault detection accuracy and communication with the Mark VI controller. Additionally, GE provides repair services for GE IS200EROCH1ADD, including functional testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term performance in industrial automation systems.