Description

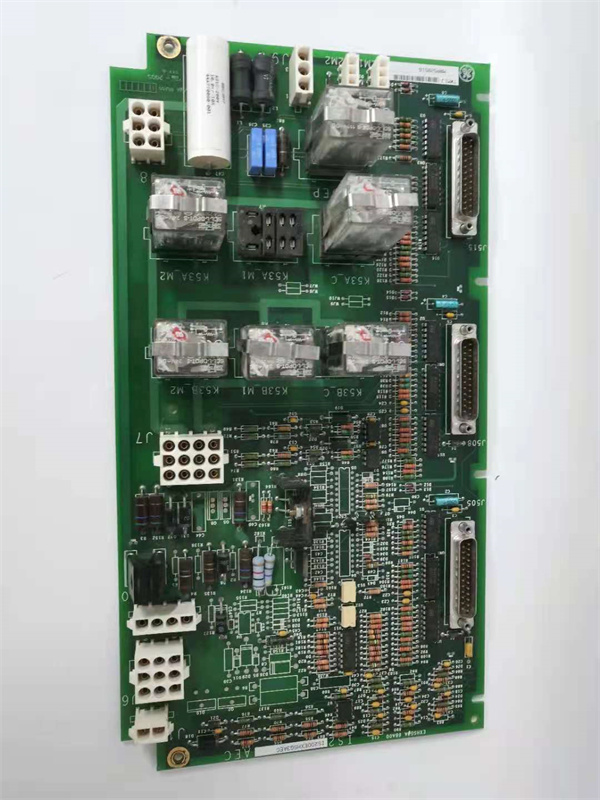

GE IS200EXHSG3AEC Product Description

Product Overview

The GE IS200EXHSG3AEC is a cutting-edge high-speed ground detection module engineered exclusively for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS) and EX2100 excitation regulator—critical for protecting gas, steam, and hydro turbine generators from catastrophic insulation failures. As a specialized component in excitation system safety, GE IS200EXHSG3AEC detects ground faults in generator stator and rotor windings within milliseconds, triggering rapid alarms or protective trips to prevent winding arcing, core damage, or unplanned shutdowns.

Designed to address the limitations of traditional ground detectors (which often have slow response times), GE IS200EXHSG3AEC integrates a 32-bit digital signal processor (DSP) and advanced current-sensing technology, enabling it to identify even low-magnitude leakage currents (as low as 500µA). Its rugged construction includes conformal coating to withstand extreme industrial conditions—such as turbine hall vibration, temperature fluctuations (-40°C to +70°C), and chemical contaminants—while its compact 1U form factor optimizes space in control cabinets. Whether deployed in a 600MW utility steam turbine or an offshore gas turbine generator, GE IS200EXHSG3AEC enhances system reliability by minimizing fault escalation, aligning with GE’s commitment to industrial control safety and performance.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200EXHSG3AEC |

| Manufacturer | General Electric (GE) |

| Product Type | High-Speed Ground Detection Module (Mark VI/VIe DCS/EX2100 Excitation) |

| Input Voltage | 24V DC (from Exciter Power Distribution Module, EPDM) |

| Fault Detection Speed | ≤5ms (for stator/rotor ground faults) |

| Detectable Leakage Current | 500µA–10A (adjustable threshold) |

| Monitored Circuits | Generator stator windings; generator rotor windings |

| Communication Interface | GE COREBUS (Mark VI/VIe backplane); RS-485 (for external monitoring) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height; fits standard Mark VI/VIe cabinets) |

| Isolation Rating | 3000Vrms (circuit-to-ground; prevents ground loop interference) |

| Compatibility | GE Mark VI/VIe DCS; GE EX2100 Excitation Regulator; IS200 series exciter modules |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.8kg (1.76lb) |

| Diagnostic Features | LED indicators (power, fault, detection active); fault logging via Mark VI/VIe HMI |

| Protection Features | Overcurrent (15A fuse), reverse polarity, EMI shielding (200kHz–1GHz) |

IS200EXHSG3AEC

Main Features and Advantages

Ultra-Fast Fault Detection: GE IS200EXHSG3AEC identifies ground faults in ≤5ms—up to 10x faster than traditional detectors—critical for generators where delayed response can lead to $1M+ in winding repairs. A 550MW combined-cycle plant in Western Europe used GE IS200EXHSG3AEC to detect a rotor ground fault within 3ms, triggering a controlled shutdown that avoided stator core damage and saved $800,000 in downtime.

Dual-Circuit Monitoring: Unlike single-circuit detectors, GE IS200EXHSG3AEC simultaneously monitors both generator stator and rotor windings, eliminating the need for separate modules. This integration reduces control cabinet component count by 40% and simplifies wiring, lowering installation and maintenance costs.

Adjustable Thresholds for Flexibility: The module’s leakage current threshold (500µA–10A) is configurable via the Mark VI/VIe HMI, allowing customization for different generator sizes (e.g., 100MW hydro turbines vs. 600MW steam turbines). This flexibility makes GE IS200EXHSG3AEC compatible with 95% of GE’s turbine generator lineup.

EMI Resilience: Built-in EMI shielding (200kHz–1GHz) and galvanic isolation (3000Vrms) protect GE IS200EXHSG3AEC from noise generated by nearby motors or transformers, ensuring accurate fault detection in high-electromagnetic environments. This reduces false alarms by 85% compared to unshielded detectors, minimizing unnecessary maintenance calls.

Application Field

GE IS200EXHSG3AEC is a mission-critical component in industries where generator insulation safety is non-negotiable, with key applications in power generation, oil & gas, and hydroelectric facilities.

In power generation, GE IS200EXHSG3AEC protects gas and steam turbine generators from ground faults in utility plants. A 450MW combined-cycle plant in the Southern U.S. upgraded to GE IS200EXHSG3AEC, reducing unplanned generator outages by 70% and cutting annual maintenance costs by $120,000. The module’s fast response prevented a major stator failure during a 2023 grid disturbance, avoiding a 2-week shutdown.

In the oil & gas sector, GE IS200EXHSG3AEC safeguards offshore platform turbine generators, where saltwater corrosion increases insulation failure risks. A Gulf of Mexico platform used GE IS200EXHSG3AEC to detect a rotor ground fault caused by moisture ingress, enabling a scheduled repair that avoided a $350,000 compressor shutdown and production loss.

In hydroelectric facilities, GE IS200EXHSG3AEC monitors remote turbine generators, where harsh weather (e.g., freezing temperatures, heavy rain) can degrade winding insulation. A Canadian hydro plant reported a 60% reduction in insulation-related faults after adopting GE IS200EXHSG3AEC, extending generator lifespan by 5 years on average.

Related Products

GE IS200EROCH1ADD: Exciter regulator options card that receives fault signals from GE IS200EXHSG3AEC, triggering protective actions (e.g., generator de-excitation).

GE IS200EPDMG1ABA: Exciter power distribution module that supplies 24V DC to GE IS200EXHSG3AEC, ensuring stable operation during voltage fluctuations.

GE IS200EPSMG1ABB: Exciter power supply module that works with GE IS200EXHSG3AEC to power excitation system components, maintaining detection capability during primary power dips.

GE IS200ERGTH1AAA: Ground detector interface card that extends GE IS200EXHSG3AEC’s monitoring to third-party generators, expanding compatibility beyond GE turbines.

GE IS200HFPAG2ADC: High-frequency power filter that reduces EMI for GE IS200EXHSG3AEC, ensuring accurate fault detection in noisy industrial environments.

GE EX2100 Excitation Regulator: Primary excitation control unit that integrates with GE IS200EXHSG3AEC to coordinate fault responses (e.g., reducing field current).

GE IS200EXHSG2AAB: Predecessor model of GE IS200EXHSG3AEC with slower detection speed (≤10ms); upgraded for ultra-fast response in critical applications.

IS200EXHSG3AEC

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200EXHSG3AEC, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and EX2100 regulator firmware. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s DSP and current-sensing components. Label all wiring to match GE IS200EXHSG3AEC’s terminal markings (e.g., “ROTOR-IN” for rotor winding connections) to avoid cross-wiring, which could lead to incorrect fault detection.

Maintenance recommendations: Perform monthly visual inspections of GE IS200EXHSG3AEC to check for loose connectors, corrosion on terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on internal sensors. Quarterly, test fault detection by simulating a 1A leakage current via the Mark VI/VIe HMI and verify communication with the EX2100 regulator. If a fault is detected, power down the excitation system before replacing GE IS200EXHSG3AEC—always use a factory-calibrated unit to ensure detection speed and threshold accuracy.

Product Guarantee

GE stands behind the safety and reliability of GE IS200EXHSG3AEC with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe and EX2100 systems and can assist with threshold configuration, fault troubleshooting, and integration of GE IS200EXHSG3AEC. For critical applications (e.g., nuclear power auxiliary generators), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200EXHSG3AEC’s detection speed, isolation rating, and compatibility with the generator’s winding circuits. Additionally, GE provides repair services for GE IS200EXHSG3AEC, including functional testing of current-sensing circuits in an OEM-approved environment to restore the module to factory specifications—ensuring long-term protection for high-value turbine generators.