Description

Product Overview

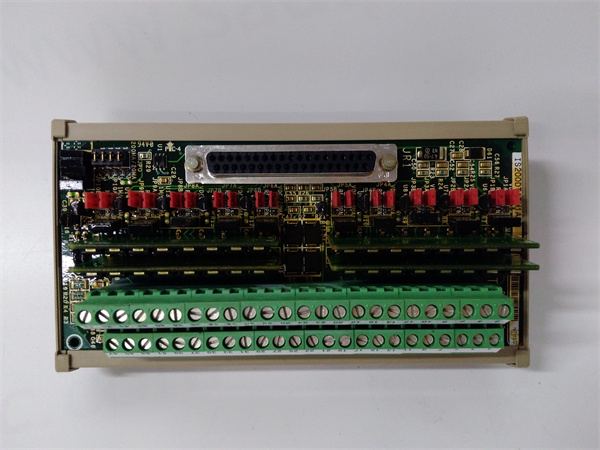

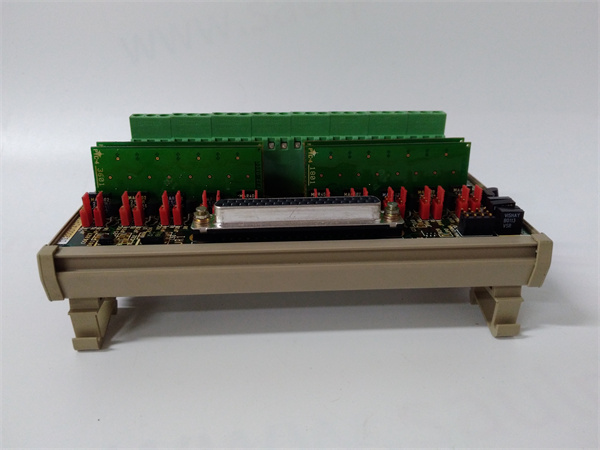

The GE IS200EXHSG3REC is a high – performance exciter high – speed relay driver board, an integral part of GE’s renowned EX2000 series. Engineered by General Electric, this board plays a crucial role in GE excitation turbine control systems, especially within the EX2100 excitation control setup.

It is designed to provide drivers for DC contactors (41) and pilot relays related to de – excitation and field flashing. The board acts as a key component in ensuring the proper operation of the excitation process in turbines. By effectively managing these relays and drivers, it contributes to the stable and reliable performance of the overall turbine system. Whether in power generation plants or industrial facilities with turbine – driven processes, the IS200EXHSG3REC helps maintain the integrity of the excitation system, enabling efficient power generation and machinery operation.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IS200EXHSG3REC

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Exciter High – Speed Relay Driver Board

|

|

Series

|

EX2000

|

|

Number of Channels

|

6

|

|

Power to Contacts

|

125 V DC

|

|

Input Voltage

|

120 V AC

|

|

Output Voltage

|

5 V to 24 V DC

|

|

Relay Break Characteristic

|

28 V DC

|

|

Operating Voltage Range

|

90 V to 265 V AC

|

|

Signal Feedback Input/Output

|

Analog (4 – 20 mA)

|

|

Communication Protocols

|

Modbus

|

|

Operating Temperature

|

0 °C to 60 °C

|

|

Mounting

|

DIN – rail

|

|

Weight

|

2.00 lbs

|

|

Size

|

3.4 in x 6.37 inch

|

|

Country of Origin

|

USA

|

|

Manual

|

GEI – 100475 A

|

IS200DTAIH1ABB

Main Features and Advantages

Reliable Relay Control: The GE IS200EXHSG3REC offers reliable relay control for both simplex and redundant control configurations. In simplex control, it manages two flashing relays, with each being driven by a pilot relay using two series contacts. For redundant control, it participates in a 2 – out – of – 3 voting circuit for three relays, enhancing system reliability. This ensures that the de – excitation and field flashing processes are accurately controlled, reducing the risk of system failures during turbine operation.

High – Speed Contactor Driver Function: The high – speed contactor drivers on the board provide a regulated constant sustaining current after the initial contactor pickup. They supply full voltage (P125) for 150 ms upon receiving an energize command, and then switch to the regulated current mode. This precise control of the contactor current is essential for the smooth operation of the high – speed contactors in the excitation system, ensuring their proper functioning and longevity.

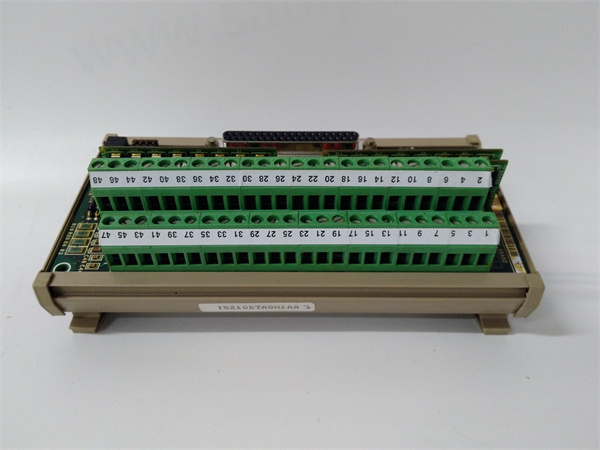

Efficient Signal Conditioning: It has an efficient signal conditioning circuit for de – excitation and contact inputs. For de – excitation, in simplex control, it monitors both inputs from the EDEX board and outputs to EMIO in M1 if either input transitions. In redundant control, it repeats the de – excitation signals from two EDEX boards to EMIO – M1 and EMIO – M2. Additionally, it monitors auxiliary contacts 53A, 53B, and 41, powering them with 70 V DC and sending the resulting status signals to EMIO. This comprehensive signal conditioning ensures accurate monitoring and control of the excitation system.

IS200DTAIH1ABB

Application Field

Power Generation Plants: In power generation plants, especially those with steam, gas, or hydro – powered turbines, the GE IS200EXHSG3REC is widely used. It is an essential part of the excitation control system that regulates the voltage and reactive power of the generators. By accurately controlling the DC contactors and pilot relays, it helps maintain stable power output, ensuring a reliable power supply to the grid.

Industrial Manufacturing with Turbine – Driven Machinery: In industrial manufacturing facilities where turbines are used to drive various machinery, such as in paper mills, textile plants, or chemical factories, this board is crucial. It ensures the proper excitation of the turbines, which in turn drives the machinery at the required speed and power. This helps in maintaining the quality of the manufacturing process and increasing production efficiency.

Oil and Gas Industry: In the oil and gas industry, turbines are used for power generation, gas compression, and other critical processes. The IS200EXHSG3REC plays a vital role in these applications by providing reliable relay control and signal conditioning for the turbine excitation systems. It helps in preventing power outages and ensuring the continuous operation of oil and gas production facilities.

Related Products

- GE IS200EXHSG3AEC: Similar to the IS200EXHSG3REC, it is also an exciter high – speed relay driver board in the EX2000 series. However, it may have different revisions or specific design optimizations. It also serves the function of driving relays in the excitation system but might have slight differences in performance or compatibility with other components.

- GE IS200EMIO: This is an exciter main input/output board. The IS200EXHSG3REC cables to three IS200EMIO boards in redundant control or one in simplex control through the IS200EBKP exciter backplane board. The IS200EMIO boards are responsible for handling the input and output signals related to the excitation process, and they work in tandem with the IS200EXHSG3REC to ensure smooth operation of the overall system.

- GE IS200EDEX: An exciter de – excitation board. The IS200EXHSG3REC receives de – excitation status signals from the IS200EDEX board. The IS200EDEX is involved in the de – excitation process of the turbine, and the IS200EXHSG3REC conditions and sends these signals to the appropriate components in the system, such as the IS200EMIO boards.

- GE IS200EBKP: An exciter backplane board. It acts as a connection medium between the IS200EXHSG3REC and the IS200EMIO boards. The IS200EBKP provides the necessary electrical connections and signal routing for the communication and operation of these boards within the excitation control system.

- GE EX2100 Series Components: The IS200EXHSG3REC is part of the EX2100 excitation control setup. Other components in the EX2100 series, such as power supply modules, control units, and additional I/O boards, work together with the IS200EXHSG3REC to form a complete excitation control system for turbines.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200EXHSG3REC, make sure all power sources related to the turbine excitation system are turned off to avoid electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as cracks on the circuit board or bent connectors. Verify the compatibility of the board with the existing EX2000/EX2100 system components, especially the connection with the IS200EMIO boards and the IS200EBKP backplane board. Ensure that the DIN – rail mounting location is clean and free from dust and debris. Have all the necessary tools, such as screwdrivers for securing the DIN – rail mount, ready for installation.

Maintenance recommendations: Regularly check the connections of the IS200EXHSG3REC to ensure they are secure. Vibrations in the industrial environment can cause connectors to loosen over time. Monitor the operating temperature of the board to ensure it remains within the specified 0 °C to 60 °C range. Check the relay operation periodically by testing the de – excitation and field flashing functions as per the system’s maintenance schedule. If any faults are detected, refer to the detailed product manual (GEI – 100475 A) provided by GE for troubleshooting steps. Clean the board gently using a static – free brush to remove accumulated dust, as dust can affect the electrical performance of the components.

Product Guarantee

GE stands firmly behind the quality of the GE IS200EXHSG3REC. The board is manufactured under strict quality control procedures to meet high – industry standards. In case of any manufacturing defects, GE offers a comprehensive warranty. Their global network of technical support teams is available to assist customers. Whether it’s providing guidance on installation, helping with troubleshooting complex issues, or offering advice on maintenance, GE’s experts are dedicated to ensuring the long – term reliable operation of the IS200EXHSG3REC. This reflects their commitment to delivering top – notch products and excellent customer service, giving users confidence in the performance and durability of the board in their critical industrial applications.