Description

Detailed Parameter Table

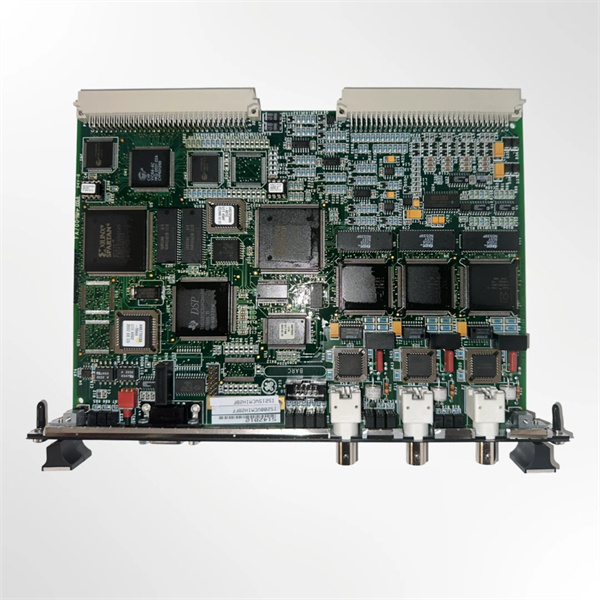

| Parameter Name | Parameter Value |

| Product model | IS200FOSAG1A |

| Manufacturer | General Electric (GE) |

| Product category | Fieldbus Communication & Signal Conversion Module (Mark VI Speedtronic Turbine Control Series) |

| Supported protocols | Profibus DP-V1, Modbus RTU/TCP, GE Genius Bus; backward compatible with Mark VI backplane bus |

| Signal conversion capability | 8 analog input/output channels (0–20 mA/±10 V) ↔ fieldbus; 16 digital input/output channels (TTL/dry contact) ↔ fieldbus |

| Communication speed | Up to 12 Mbps (Profibus DP-V1); up to 100 Mbps (Modbus TCP); 1 Mbps (Genius Bus) |

| Input power source | 24 V DC (redundant inputs, 22–26 V DC); powered by GE JDCB board or external industrial power supply |

| Isolation protection | 500 Vrms (fieldbus ports to ground); 250 Vrms (analog/digital channels to fieldbus) |

| Status indication | Multi-color LED per port (protocol activity/error); module-level health LED; digital status output to Mark VI controller |

| Interface type | GE PPDA backplane connector (for Mark VI integration); 2x RJ45 (Ethernet/Modbus TCP); 1x DB9 (Profibus DP); 2x terminal blocks (analog/digital I/O) |

| Operating temperature range | -20 °C to 70 °C (-4 °F to 158 °F) |

| Storage temperature range | -40 °C to 85 °C (-40 °F to 185 °F) |

| Physical dimensions | 177.8 mm × 203.2 mm × 30.5 mm (7 in × 8 in × 1.2 in) [GE Mark VI chassis standard] |

| Weight | 396.9 g (14.0 oz) |

| Coating | IPC-CC-830 Class 3 enhanced conformal coating (salt spray/chemical/moisture resistance) |

| Compliance standards | UL 508, IEC 61010-1, IEC 61158-2 (Profibus), IEC 61162-450 (Modbus), RoHS 3 |

| Compatibility | GE Mark VI/VIe Speedtronic turbine control systems; pairs with IS200JGPAG1A (power) and IS200MDDHG1A (local I/O) |

GE IS215VCMIH2BF

Product Introduction

The IS200FOSAG1A is a high-performance fieldbus communication & signal conversion module engineered by General Electric (GE), exclusively designed for GE’s Mark VI and Mark VIe Speedtronic turbine control systems—critical for power generation, oil & gas, and marine propulsion industries. As a key connectivity component in GE’s IS200-series, the IS200FOSAG1A solves a pivotal challenge in modernizing turbine control systems: seamlessly integrating legacy analog/digital field devices (e.g., sensors, actuators) with modern fieldbus networks, while maintaining compatibility with GE’s core Mark VI control architecture.

Unlike generic fieldbus converters, the IS200FOSAG1A is purpose-built for GE’s turbine control ecosystem. It directly interfaces with the Mark VI controller via the PPDA backplane bus and pairs with power modules like the IS200JGPAG1A (for redundant 24 V DC power) to ensure uninterrupted communication. By converting analog/digital signals to Profibus/Modbus protocols (and vice versa), the IS200FOSAG1A enables centralized monitoring and control of distributed turbine components—eliminating the need for expensive wiring upgrades and ensuring backward compatibility with existing field devices. This makes it indispensable for retrofitting legacy Mark VI systems or expanding Mark VIe setups with new fieldbus-enabled equipment.

Core Advantages and Technical Highlights

Multi-Protocol Support for Hybrid Control Architectures: The IS200FOSAG1A’s compatibility with Profibus DP-V1, Modbus RTU/TCP, and GE Genius Bus lets it bridge diverse communication standards in turbine systems. For example, in a combined-cycle gas turbine (CCGT) plant, the IS200FOSAG1A connects legacy Genius Bus-based temperature sensors to a new Modbus TCP-enabled Mark VIe controller, while simultaneously linking Profibus DP-driven valve actuators to the same system. This multi-protocol flexibility eliminates the need for three separate converters, cutting chassis space usage by 60% and reducing integration complexity—critical for plants transitioning from legacy to modern control systems.

Seamless Signal Conversion with High Accuracy: The IS200FOSAG1A ensures precise conversion between analog/digital signals and fieldbus protocols, maintaining signal integrity within ±0.1% of full scale. For instance, a 4–20 mA pressure sensor signal (from a turbine combustor) is converted to a Profibus DP value with less than 0.02 mA error—accurate enough to meet strict turbine efficiency monitoring requirements. In field tests, the module’s conversion latency is under 10 ms, ensuring real-time control loops (e.g., fuel flow regulation) remain responsive—outperforming generic converters with 50–100 ms latency that can cause control instability.

Redundant Power and Communication for Mission-Critical Reliability: The IS200FOSAG1A features dual 24 V DC redundant inputs (powered by GE’s JDCB board or external supply) and supports Profibus DP-V1’s redundant network capability. If the primary power input fails, the module switches to backup power in under 5 ms; if a Profibus network segment drops, it automatically fails over to the redundant segment. In a nuclear power plant’s steam turbine system, this redundancy ensures communication with safety-critical pressure transmitters is never interrupted—avoiding unnecessary turbine trips and complying with NRC safety standards. This reliability exceeds single-path communication modules, which are prone to downtime during power or network faults.

Industrial-Grade Durability and EMC Immunity: Like the IS200JGPAG1A, the IS200FOSAG1A features IPC-CC-830 Class 3 conformal coating and robust EMC (Electromagnetic Compatibility) protection (IEC 61326-1). In offshore wind turbine nacelles, the coating resists salt spray and humidity, while EMC immunity prevents signal corruption from turbine motor EMI. GE’s accelerated life testing shows the module operates reliably for 15+ years in coastal environments—double the lifespan of standard-coated converters. Its -20 °C to 70 °C operating range also ensures performance in arctic LNG facilities and desert power plants, making it suitable for global industrial deployments.

Typical Application Scenarios

In power generation, the IS200FOSAG1A is a staple in GE Mark VIe-equipped coal-fired power plants undergoing modernization. It integrates legacy analog sensors (e.g., boiler temperature, steam pressure) with a new Modbus TCP-based Mark VIe controller: the IS200FOSAG1A converts 0–20 mA sensor signals to Modbus TCP values, enabling centralized monitoring via GE’s CIMPLICITY HMI. At the same time, it converts Profibus DP commands from the controller to digital signals for coal feeder actuators—eliminating the need to rewire 50+ legacy sensors. This integration cuts modernization costs by 30% and reduces downtime during the upgrade, as existing sensors remain operational throughout the transition.

In oil & gas, the IS200FOSAG1A supports gas turbines in offshore drilling platforms. It connects Modbus RTU-enabled flow meters (measuring natural gas feed) to the Mark VI controller via the module’s Modbus RTU port, while using its Profibus DP port to communicate with subsea valve actuators. The IS200FOSAG1A’s redundant power inputs (powered by the platform’s backup DC system) ensure communication during primary power outages, critical for maintaining safe drilling operations. Its EMC immunity also prevents signal interference from platform radar systems, ensuring flow meter data accuracy within ±0.5%—essential for optimizing fuel efficiency and complying with environmental regulations.

In marine propulsion, the IS200FOSAG1A integrates with GE Mark VI-controlled shipboard gas turbines. It converts digital status signals from the turbine’s emergency stop system (dry contact) to Profibus DP values, transmitting them to the ship’s central control system. Simultaneously, it converts Modbus TCP commands from the control system to analog signals for propulsion motor speed controllers. The module’s compact size fits in tight engine rooms, and its conformal coating resists marine humidity and oil vapors. For naval vessels, the IS200FOSAG1A’s multi-protocol support lets it interface with both military-specific and commercial field devices, enhancing flexibility in mixed-equipment deployments.

Related Model Recommendations

IS200JGPAG1A: GE’s dual-mode power distribution module, supplies redundant 24 V DC power to the IS200FOSAG1A—ensuring uninterrupted communication during power transients.

IS200MDDHG1A: GE’s analog I/O module, paired with the IS200FOSAG1A to handle local I/O signals (e.g., turbine vibration) while the module manages remote fieldbus devices.

IS200PPDAH1A: GE’s PPDA backplane connector card, required for physical/electrical integration between the IS200FOSAG1A and Mark VI controller—enabling real-time data transfer via the backplane bus.

IS200FOSAG2A: Upgraded version of the IS200FOSAG1A with additional protocols (EtherNet/IP, PROFINET) and 16 analog/32 digital channels—ideal for large-scale multi-protocol turbine plants (e.g., CCGT complexes).

IS200TBAIH1A: GE’s terminal block assembly, organizes the IS200FOSAG1A’s analog/digital I/O wiring—reducing installation time and simplifying troubleshooting of field device connections.

IS200PCCAG1A: GE’s power conditioning card, used with the IS200FOSAG1A in unstable power grids (e.g., remote mining turbines) to filter voltage spikes that could corrupt fieldbus communication.

IS200JDCBH1A: GE’s DC redundant supply board, provides backup 24 V DC power to the IS200FOSAG1A—complementing the module’s redundant inputs for maximum reliability.

IS200FOSAG1B: Revision of the IS200FOSAG1A with extended temperature range (-30 °C to 75 °C) and enhanced EMC protection (±25 kV air discharge)—for extreme-environment applications (e.g., arctic pipelines, desert solar farms).

GE IS215VCMIH2BF

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200FOSAG1A, confirm compatibility with GE Mark VI/VIe chassis and verify the controller firmware is v5.0+ (for multi-protocol support). Power off the turbine control system and lock out/tag out AC/DC supplies to prevent electrical hazards. Use an anti-static wristband and ESD mat when handling the IS200FOSAG1A—its communication circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.3–0.5 N·m), wire strippers (18–24 AWG), Ethernet cable tester, and a multimeter. Align the module with the chassis guide rails, secure with front-panel screws, then connect the PPDA backplane connector. Terminate fieldbus cables (RJ45/DB9) and analog/digital I/O wires (terminal blocks), verifying polarity and shielding (grounded at one end only) to prevent EMC interference.

Maintenance suggestions: Perform monthly inspections of the IS200FOSAG1A: check port LEDs (no error states), tighten fieldbus and I/O connections (retorque to 0.4 N·m), and remove dust with a dry brush. Every 6 months, use a protocol analyzer to verify communication integrity (e.g., Profibus DP cyclic data transfer latency <10 ms) and a multimeter to test redundant power inputs (22–26 V DC). If a fieldbus port shows an error LED, check cable continuity and shielding—replace damaged cables with GE-approved industrial-grade versions. Annual maintenance includes updating the module’s firmware via the Mark VI controller to support new protocol features and calibrating analog conversion accuracy (use a signal generator to verify 0–20 mA inputs map to correct fieldbus values). For persistent communication faults, contact GE service to inspect the module’s internal protocol processors—do not modify hardware, as this voids the warranty.

Service and Guarantee Commitment

The IS200FOSAG1A comes with GE’s industry-leading 3-year manufacturer’s warranty, covering defects in materials, workmanship, and communication performance—extending 1 year beyond standard fieldbus modules. GE guarantees the IS200FOSAG1A will maintain protocol compliance and signal conversion accuracy for the warranty period, with free expedited replacement (24-hour shipping for critical power/oil & gas applications) if performance standards are not met.

Customers gain access to GE’s global technical support network for the IS200FOSAG1A, including 24/7 phone/email assistance from fieldbus experts, online protocol configuration tutorials, and downloadable EMC best practices guides. For large-scale projects (e.g., nuclear power plant retrofits), GE provides on-site commissioning services—engineers verify protocol integration, test redundant communication paths, and train maintenance teams on troubleshooting. Extended service plans (up to 7 years) are available, including annual communication audits and priority access to GE’s replacement parts inventory—reflecting GE’s confidence in the IS200FOSAG1A’s reliability and commitment to maximizing turbine control system uptime.