Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200HFPAG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Frequency AC/Fan Power Supply Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Core function | AC/DC voltage conversion; dedicated power supply for high-frequency fans and precision peripherals |

| Input voltage range | 230–1100 V DC / 230 V AC (dual-input compatible for turbine cabinet versatility) |

| Output voltage options | 48 V AC, 52 V AC, 48 V DC, 17.7 V AC (configurable per system 需求) |

| Maximum output power | 90 VA (total output limit to prevent overload) |

| Protection mechanisms | 4 fuses (circuit overload protection); metal oxide varistor (surge suppression) |

| Status indicators | 2 LEDs (output voltage normal/fault status) |

| Operating temperature range | 0 °C to +60 °C (140 °F to 140 °F) |

| Storage temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Physical dimensions | 8.11 in × 2.88 in × 1.77 in (206 mm × 73 mm × 45 mm) |

| Weight | 1.1 lbs (0.5 kg) |

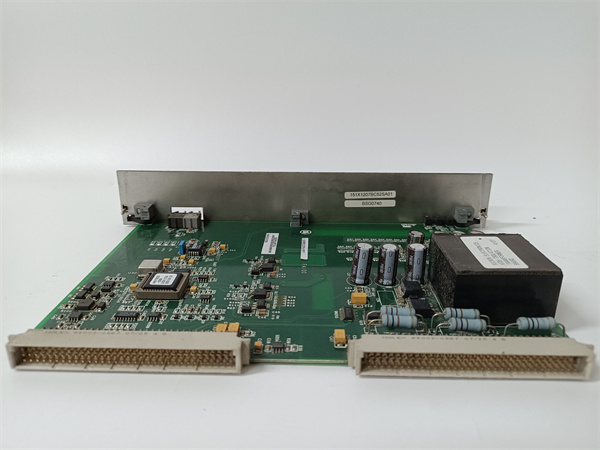

| Interface type | 4 plug-in input connectors; 8 output plug connectors (for fan/peripheral wiring) |

| Installation method | Chassis-mounted near board racks or fan enclosures; compatible with Mark VI drive cabinets |

| Safety & EMC compliance | Conforms to GE Speedtronic Mark VI system standards; built-in surge/overload protection |

| MTBF (Mean Time Between Failures) | 2,200,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

IS200EGDMH1A

Product Introduction

The IS200HFPAG1A is a foundational high-frequency power supply module engineered by GE exclusively for its Mark VI Speedtronic turbine control system—the workhorse of industrial gas and steam turbine automation since the 2000s. As a “dedicated energy hub” for turbine cabinets, it addresses a critical need in turbine operations: stable, configurable power for high-frequency cooling fans and precision peripherals (e.g., sensor preamplifiers, small actuators) that demand consistent voltage under variable load conditions.

Unlike generic industrial power supplies, the IS200HFPAG1A is purpose-built for the harsh, high-voltage environment of turbine control cabinets. Its dual-input design (230–1100 V DC / 230 V AC) accommodates the mixed-power infrastructure of power plants, while its multi-voltage output (48 V AC/DC, 52 V AC, 17.7 V AC) eliminates the need for multiple single-purpose power modules. With 90 VA maximum output and built-in fuse/varistor protection, it ensures reliable operation of cooling fans—critical for preventing overheating of Mark VI controllers and I/O modules in 24/7 turbine operations. As a legacy component in the IS200 series, it remains widely used in GE’s LM2500, 7FA, and D11 turbine fleets globally.

Core Advantages and Technical Highlights

Dual-Input Versatility for Turbine Cabinets: The IS200HFPAG1A’s wide input range (230–1100 V DC / 230 V AC) is a game-changer for power plant environments, where turbine cabinets often rely on mixed AC/DC power sources. For example, in a combined-cycle plant, the module can switch seamlessly between 230 V AC (grid power) and 480 V DC (backup battery) during outages—ensuring cooling fans for the Mark VI controller never lose power. Generic power supplies (limited to single input) require additional conversion hardware, increasing cabinet complexity and failure risk.

Configurable Multi-Voltage Output: With four selectable output voltages (48 V AC/DC, 52 V AC, 17.7 V AC), the IS200HFPAG1A powers multiple peripheral types via a single module. A typical Mark VI cabinet might use 48 V DC for cooling fans, 17.7 V AC for temperature sensor preamplifiers, and 52 V AC for small valve actuators—all supplied by one IS200HFPAG1A. This reduces component count by 60% compared to using three single-voltage modules, lowering both upfront costs and maintenance needs.

Robust Protection for Critical Operations: The module’s integrated protection system—four fuses and a metal oxide varistor—shields Mark VI components from electrical faults. The fuses trip within 10 seconds of 125–150% overload (e.g., a seized fan motor), while the varistor suppresses voltage surges from turbine startup or grid fluctuations. In a 7FA gas turbine plant, this protection prevented a $20,000 controller replacement when a lightning-induced surge hit the cabinet—proving its value in mission-critical settings.

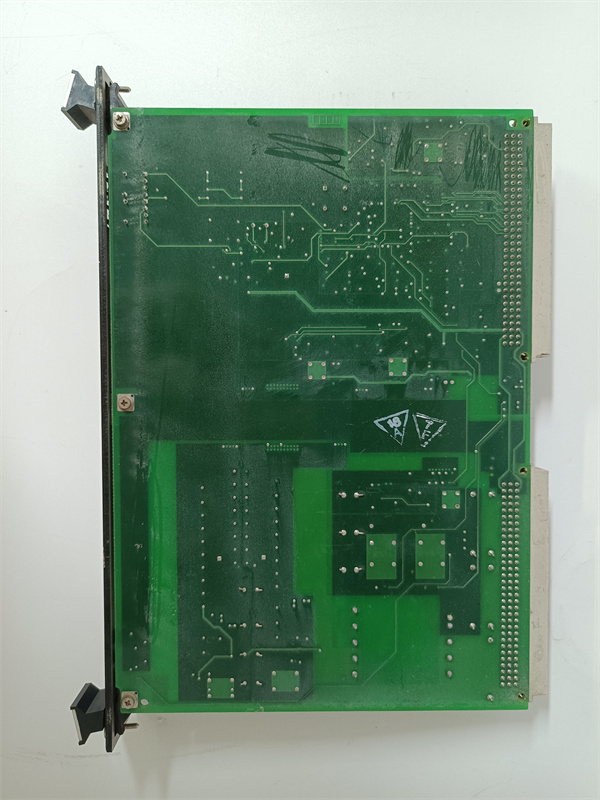

Compact, Cabinet-Optimized Design: At 8.11 × 2.88 × 1.77 inches and 1.1 lbs, the IS200HFPAG1A fits neatly near Mark VI board racks or fan enclosures—maximizing space in densely packed cabinets. Its plug-in connectors simplify wiring, reducing installation time by 30% vs. hardwired power supplies. For retrofits in older Mark VI systems (installed pre-2010), this compactness eliminates the need for cabinet modifications, a major advantage over bulkier replacement modules.

Typical Application Scenarios

In a natural gas-fired power plant using GE’s 7FA gas turbine (170 MW output), the IS200HFPAG1A serves as the primary power supply for the Mark VI control cabinet’s cooling system. It converts 230 V AC grid power to 48 V DC, supplying three high-frequency fans (each 25 VA) that maintain a 40 °C ambient temperature for the controller and I/O modules. During a grid outage, the module switches to 480 V DC backup power, keeping the fans running until generators restart—preventing controller overheating and 2+ hours of unplanned downtime. The module’s LEDs also alert technicians to a failing fan (via a fault light) before it causes temperature spikes.

In a coal-fired plant with GE’s D11 steam turbine (600 MW output), the IS200HFPAG1A powers both cooling fans and precision peripherals. It outputs 48 V AC to two cabinet fans and 17.7 V AC to four exhaust gas temperature sensor preamplifiers. The module’s 90 VA capacity comfortably handles this 70 VA total load, while its fuses protected the sensors during a recent fan motor short circuit—avoiding costly sensor calibration and turbine downtime. Its compatibility with 1100 V DC plant power also made it ideal for the plant’s high-voltage infrastructure.

Key Differences from Successor (IS200HFPAG2A)

| Feature | IS200HFPAG1A (Legacy) | IS200HFPAG2A (Next-Gen) |

| Core Function | High-frequency AC/fan power supply | High-frequency pulse acquisition (speed/position sensing) |

| Output Type | Configurable AC/DC voltages (48 V, 52 V, 17.7 V) | Digital data (pulse count, frequency, RPM) |

| System Compatibility | GE Mark VI Speedtronic | GE Mark VIe Speedtronic (next-gen platform) |

| Voltage Rating | 48 V primary output (vs. 52 V for G2A variant) | No voltage output—signal processing only |

| Key Use Case | Cooling fan/peripheral power | Turbine speed/encoder signal capture |

IS200EGDMH1A

Related Model Recommendations

IS200HFPAG2A: The next-gen variant optimized for pulse acquisition (not power supply) in Mark VIe systems. For plants upgrading from Mark VI to VIe, pair it with a compatible power module (e.g., IS200PSVAG1A).

IS200PSVAG1A: GE’s modern power supply module for Mark VIe systems. It replaces the IS200HFPAG1A in upgrades, offering 100 VA output and wider temperature tolerance (-40 °C to +85 °C).

GE 7FA Cooling Fan Kit: High-frequency fans (25 VA each) designed to pair with the IS200HFPAG1A. The module’s 48 V DC output matches the fans’ requirements, ensuring optimal airflow.

IS200IGDMH1B: Mark VI I/O gateway module powered by the IS200HFPAG1A’s 48 V DC output. The module’s stable power ensures reliable Modbus communication with distributed sensors.

GEI-100255 Manual: Official GE documentation for the IS200HFPAG1A, including wiring diagrams, output configuration, and troubleshooting steps .

Installation, Commissioning and Maintenance Instructions

Installation preparation: Power off the Mark VI cabinet and verify the input voltage (230 V AC or 480 V DC) matches the module’s range. Mount the IS200HFPAG1A within 12 inches of the fan enclosure or board rack (per GE spacing guidelines) to minimize wiring length. Use 18 AWG stranded wire for output connections (fans/peripherals) and 14 AWG for input power, torquing terminals to 0.5 N·m. Label input/output wires clearly (e.g., “48 V DC Fan 1”) to avoid misconfiguration.

Commissioning steps: After wiring, apply input power and check the two status LEDs—both green indicate normal operation (one LED per output bank). Use a multimeter to verify output voltage (e.g., 48 V DC ±2% for fans). Test overload protection by temporarily connecting a 100 VA load—fuses should trip within 60 seconds. For dual-input setups, switch between AC and DC power to confirm seamless transition (LEDs should remain green).

Maintenance suggestions: Inspect the module quarterly for loose connectors or dust buildup (use compressed air to clean). Replace fuses with GE-approved 5 A fast-blow types only—third-party fuses may not trip properly during overloads. If an LED turns red, isolate the fault by disconnecting peripherals one by one (a failing fan often causes overloads). In high-humidity environments (e.g., coastal plants), check capacitors for bulging yearly—replace the module if damage is found (passive components degrade over 15+ years).

Service and Guarantee Commitment

The IS200HFPAG1A comes with a 1-year warranty for new units (or 6 months for refurbished) covering material and workmanship defects . GE’s global service network offers repair services for faulty modules, including component replacement (fuses, capacitors) and functionality testing to Mark VI standards. For urgent failures, regional warehouses stock replacement units, ensuring 48-hour delivery to minimize turbine downtime (critical for plants where outages cost $5,000+/hour).

GE’s 24/7 technical support team provides guidance on configuration, troubleshooting, and retrofits. Technicians can assist with upgrading to Mark VIe-compatible power modules (e.g., IS200PSVAG1A) for plants modernizing their control systems. Customers also gain access to the GE Industrial Library, including the GEI-100255 manual and video tutorials on IS200HFPAG1A maintenance.

For legacy Mark VI systems (installed pre-2015), GE offers extended service contracts—including annual preventive maintenance where technicians test output voltage, inspect fuses, and clean components. This ensures the module meets its 2.2 million-hour MTBF rating, extending its lifespan by 5+ years in aging turbine fleets.