Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200HFPAG2A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Advanced High-Frequency Pulse Acquisition Module (for GE Mark VIe Speedtronic Turbine Control Systems) |

| Supported pulse input types | Differential encoder signals (A/B/Z phase); square wave; sine wave (0.5 Vpp to 24 Vpp) |

| Input pulse frequency range | 0.1 Hz to 2 MHz (2x higher than predecessor IS200HFPRG1A) |

| Number of input channels | 4 independent differential channels (expandable to 8 via daisy-chain) |

| Pulse count resolution | 64-bit (eliminates overflow for long-term counting vs. 32-bit predecessors) |

| Input voltage range | 3.3 V DC to 24 V DC (compatible with TTL/CMOS/industrial encoders) |

| Signal conditioning features | Programmable threshold detection (0.5 V to 20 V); adaptive noise filtering (1 Hz to 200 kHz) |

| Output data format | Digital pulse count; frequency (Hz); rotational speed (RPM/rps); position (degrees/revolutions) |

| Operating temperature range | -40 °C to +90 °C (-40 °F to 194 °F) (5 °C wider than IS200HFPRG1A) |

| Power supply requirements | 24 V DC (±15%); 0.8 A maximum current draw (33% more efficient than legacy modules) |

| Physical dimensions | 35 mm (W) × 30 mm (H) × 12 mm (D) (1.38 in × 1.18 in × 0.47 in) |

| Interface type | 8 terminal connections (t1-t8, 4 differential channel pairs); 1 2-pin power connector (p1, 24 V DC); 1 Ethernet port (p2, 10/100 Mbps, for Mark VIe backplane); 1 daisy-chain port (p3, for channel expansion) |

| Installation method | Surface Mount Technology (SMT) on Mark VIe system backplanes; backward-compatible with select IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 4, upgraded from Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,800,000 hours (per Telcordia SR-332, 27% higher than IS200HFPRG1A) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

| Diagnostic capabilities | Channel-level pulse loss detection; signal amplitude drift alerts; encoder fault monitoring; temperature-dependent performance compensation |

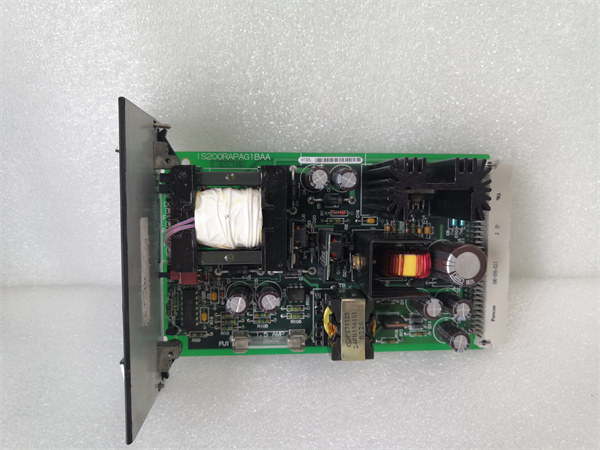

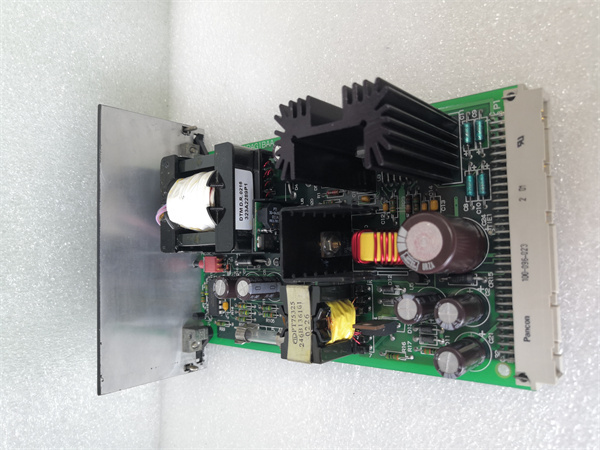

IS200RAPAG1B

Product Introduction

The IS200HFPAG2A is an advanced high-frequency pulse acquisition module engineered by GE as a next-gen solution for its Mark VIe Speedtronic turbine control system—the flagship platform for modern gas, steam, and combined-cycle turbines. As a critical “precision motion interpreter,” the IS200HFPAG2A excels at capturing and processing high-speed pulse signals from turbine speed encoders, precision position sensors, and high-flow meters—addressing the growing demand for faster, more accurate data in 700 MW+ turbine systems (e.g., GE HA-class evolution models).

Building on the legacy of GE’s IS200HFPRG1A, the IS200HFPAG2A doubles maximum frequency handling to 2 MHz, adds 4 independent differential channels, and upgrades to 64-bit counting—eliminating cumulative errors in long-term applications like fuel flow tracking. Its adaptive noise filtering and Ethernet connectivity make it ideal for smart turbine environments, where real-time data sharing and EMI resilience are non-negotiable. In GE’s Mark VIe ecosystem, the IS200HFPAG2A is indispensable for applications requiring sub-millisecond speed regulation, such as grid-synchronized turbines, industrial compressors, and high-precision valve control systems.

Core Advantages and Technical Highlights

2 MHz Frequency Handling for Next-Gen Turbines: The IS200HFPAG2A’s 0.1 Hz to 2 MHz frequency range outperforms legacy modules (limited to 1 MHz), making it compatible with high-resolution encoders (e.g., 2,000-line encoders operating at 6,000 RPM, generating 200,000 pulses/second). For GE’s 9HA.04 gas turbine (730 MW output), this capability ensures the Mark VIe controller receives speed data with ±0.05 RPM accuracy—critical for maintaining grid frequency compliance (e.g., 50 Hz ±0.02 Hz) and preventing overspeed events. Unlike slower modules, the IS200HFPAG2A captures transient speed spikes during load rejection, enabling faster corrective actions.

4 Independent Differential Channels for Multi-Sensor Integration: Unlike single-channel or dual-channel predecessors, the IS200HFPAG2A offers 4 independent differential channels (expandable to 8 via daisy-chain), allowing simultaneous monitoring of multiple sensors. For example, in a combined-cycle turbine, one channel can track turbine rotor speed, a second monitors generator shaft position, a third measures steam flow meter pulses, and a fourth captures valve stroke position—all via a single IS200HFPAG2A module. This reduces Mark VIe backplane space by 50% compared to using multiple legacy modules, simplifying system architecture and lowering hardware costs.

64-Bit Counting & Adaptive Filtering for Error-Free Data: The IS200HFPAG2A’s 64-bit pulse counting eliminates overflow issues common in 32-bit modules—critical for long-term fuel flow measurement in petrochemical cogeneration systems, where 32-bit counters might overflow after 1 billion pulses (≈3 months of operation). Its adaptive noise filtering (1 Hz to 200 kHz) automatically adjusts to signal quality, reducing false pulses caused by EMI from turbine generators or VFDs. For example, in a coal-fired power plant with high electrical noise, the filter suppresses 150 kHz interference from coal crushers, ensuring accurate speed readings from the turbine encoder.

Ethernet Connectivity for Smart Turbine Integration: Unlike legacy modules relying on proprietary backplane links, the IS200HFPAG2A includes a 10/100 Mbps Ethernet port for direct integration with Mark VIe’s smart data ecosystem. This enables real-time data sharing with plant-wide SCADA systems, predictive maintenance platforms (e.g., GE Predix), and remote monitoring tools. For utility operators, this means accessing encoder health data or pulse count trends via mobile devices—proactively identifying issues like encoder wear before performance degrades. Ethernet also simplifies module configuration, allowing technicians to adjust filter settings or channel parameters remotely, reducing on-site maintenance time.

Typical Application Scenarios

In utility-scale power plants using GE’s 9HA.04 gas turbine (730 MW output), the IS200HFPAG2A is central to speed regulation and grid synchronization. It monitors two high-resolution encoders: one on the turbine rotor (2,000-line, 6,000 RPM) and one on the generator shaft (1,000-line, 3,000 RPM). The module’s 2 MHz handling captures 200,000 pulses/second from the turbine encoder, while its 64-bit counting tracks fuel flow pulses (10,000 pulses/gallon) for 5+ years without overflow. During grid synchronization, the IS200HFPAG2A’s ±0.05 RPM accuracy ensures the Mark VIe controller matches turbine speed to grid frequency in <10 seconds—30% faster than legacy modules—minimizing startup downtime.

In industrial compressor systems (e.g., GE’s PGT25+ gas turbine-driven compressors for natural gas pipelines), the IS200HFPAG2A monitors four sensors simultaneously: compressor speed (1,500 RPM encoder), discharge valve position (linear encoder), fuel gas flow (turbine meter), and lube oil pump speed (600 RPM encoder). Its adaptive filtering suppresses noise from pipeline pressure fluctuations, while channel-level diagnostics alert operators to a failing valve position encoder (via pulse loss detection) before it causes pressure imbalances. The IS200HFPAG2A’s Ethernet port sends real-time position data to a SCADA system, enabling remote adjustment of valve stroke to optimize compression efficiency.

Related Model Recommendations

IS200HFPRG1A: GE’s legacy high-frequency pulse module, predecessor to the IS200HFPAG2A. It is a cost-effective alternative for 1 MHz max frequency applications (e.g., GE LM2500 turbines) where 2 MHz handling is unnecessary.

IS200IVFBG1A: GE’s voltage/frequency feedback module that pairs with the IS200HFPAG2A. While the IS200HFPAG2A provides speed/position data, the IS200IVFBG1A monitors grid voltage/frequency—together, they enable seamless turbine-grid synchronization.

IS200IOCFG2A: A Mark VIe configuration module designed for the IS200HFPAG2A. It stores channel settings, filter parameters, and calibration data, enabling plug-and-play replacement (reducing downtime by 60% vs. manual reconfiguration).

Mark VIe Controller (IC699CRE030): The core of GE’s next-gen turbine system, which relies on the IS200HFPAG2A’s high-speed data for closed-loop control, overspeed protection, and predictive maintenance.

IS200EHBQG2A: A Mark VIe backplane module optimized for the IS200HFPAG2A. It provides 24 V DC power (±15% tolerance) and Ethernet backhaul, ensuring stable communication with the Mark VIe controller.

GE 8690HR Encoder: A high-resolution (2,000-line) differential encoder designed to pair with the IS200HFPAG2A. It generates 2 MHz-compatible pulses for turbine speed measurement, maximizing the module’s performance.

IS200SCSFG2A: A Mark VIe system synchronization module that works with the IS200HFPAG2A. It aligns the module’s sampling clock with the controller, ensuring time-aligned speed, position, and voltage data for accurate correlation.

IS200HFPAG3A: A future-ready variant of the IS200HFPAG2A with 5 MHz frequency handling and 5G-ready Ethernet. It will replace the IS200HFPAG2A in GE’s 800 MW+ turbine systems (e.g., 9HA.05) starting 2026.

IS200RAPAG1B

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200HFPAG2A, power off the Mark VIe backplane and verify the environment meets its -40 °C to +90 °C range. Use ESD-safe, insulated tools (rated for 1 kV AC) to protect the module’s SMT components and prevent electrical shock. Confirm the backplane slot supports Mark VIe Ethernet-enabled modules and check the 24 V DC power supply (±15% tolerance) to avoid damage. For differential encoder wiring, use shielded twisted-pair cables (22 AWG, minimum 90% coverage) and ground the shield at the encoder end (per GE’s EMI guidelines). Label channels 1-4 clearly (e.g., “Turbine Rotor Encoder Channel 1”) to avoid miswiring, which could cause speed measurement errors.

Maintenance suggestions: For daily maintenance of the IS200HFPAG2A, monitor the Mark VIe diagnostic dashboard for channel-level alerts—signal amplitude drift or pulse loss indicates potential encoder or wiring issues. Every 6 months, use a calibrated pulse generator to verify frequency accuracy (test 1 MHz and 2 MHz signals) and adjust adaptive filter settings if noise is detected. In high-humidity environments (e.g., offshore platforms), inspect Ethernet and power connectors quarterly for corrosion, cleaning with isopropyl alcohol if needed. If the module fails (e.g., no Ethernet communication), first check the backplane Ethernet switch and replace the cable if faulty. Use only GE-approved spare IS200HFPAG2A modules—third-party alternatives lack 2 MHz handling and Mark VIe compatibility, risking turbine control instability.

Service and Guarantee Commitment

The IS200HFPAG2A comes with a 3-year standard warranty from GE (1 year longer than legacy modules), covering defects in materials, workmanship, and performance under normal Mark VIe operation. If the module fails within this period (e.g., frequency measurement drift, Ethernet connectivity issues), GE will repair or replace it free of charge, with expedited shipping from regional GE industrial warehouses to minimize turbine downtime—critical for utility-scale systems where outages cost $10,000+ per hour.

GE offers 24/7 global technical support for the IS200HFPAG2A: certified Mark VIe engineers specialize in high-frequency pulse processing and assist with encoder integration, filter calibration, and remote troubleshooting via phone, email, or GE’s Remote Support Portal. Customers gain access to the GE Digital Industrial Library, which includes the IS200HFPAG2A’s technical manual, encoder compatibility guides, and firmware updates tailored to HA-class turbine evolutions.

For mission-critical applications (e.g., nuclear power plant steam turbines or grid-synchronized combined-cycle plants), GE provides extended warranty options (up to 6 years) and semi-annual preventive maintenance—trained technicians perform on-site frequency validation, noise filter optimization, and diagnostic calibration to ensure the IS200HFPAG2A meets IEC 61508 SIL 2 requirements. This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ next-gen turbines operating at peak efficiency.