Description

GE IS200HFPAG2ADC Product Description

Product Overview

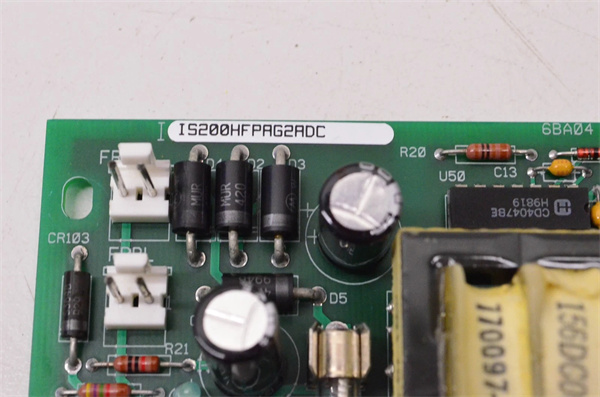

The GE IS200HFPAG2ADC is a specialized high-frequency power filter and adapter module engineered exclusively for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), critical for mitigating high-frequency electromagnetic interference (EMI) in turbine excitation and control circuits. As a key component in gas, steam, and combined-cycle turbine architectures, GE IS200HFPAG2ADC filters high-frequency noise (200kHz–1GHz) from power supplies and signal lines, ensuring stable power delivery to sensitive components like the GE IS200EPSMG1ABB (exciter power supply) and GE IS200EROCH1ADD (exciter regulator options card).

Designed to address EMI-related performance issues in industrial environments, GE IS200HFPAG2ADC integrates advanced ferrite cores and capacitor networks, attenuating noise by up to 40dB—far exceeding standard power filters. Its rugged construction includes conformal coating and a metal shielding enclosure, withstanding extreme temperatures (-40°C to +70°C), vibration, and industrial contaminants. By protecting critical control circuits from high-frequency interference, GE IS200HFPAG2ADC prevents false alarms, signal corruption, and component damage, directly enhancing turbine operational reliability. Whether deployed in a 500MW utility steam turbine or an offshore gas turbine compressor, GE IS200HFPAG2ADC ensures consistent power quality and control system integrity.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200HFPAG2ADC |

| Manufacturer | General Electric (GE) |

| Product Type | High-Frequency Power Filter & Adapter Module (Mark VI/VIe DCS) |

| Input Voltage | 24V DC (18–30V DC operating range); compatible with redundant power supplies |

| Filter Frequency Range | 200kHz–1GHz (attenuation: 40dB typical at 100MHz) |

| Output Current Rating | 10A continuous (15A peak for 10s) |

| Connection Type | Terminal blocks (input: 2x; output: 2x) + 50-pin backplane connector |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 equivalent for dust/humidity) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe control cabinets |

| Isolation Rating | 2500Vrms (input-to-output; prevents ground loops) |

| Compatibility | GE Speedtronic Mark VI/VIe DCS; IS200 series exciter/power modules |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.9kg (1.98lb) |

| Diagnostic Features | LED indicators (power active, filter fault); fault logging via Mark VI/VIe HMI |

| Protection Features | Overcurrent (15A thermal fuse), reverse polarity, surge protection (6kV ESD) |

IS200HFPAG2ADC

Main Features and Advantages

High-Frequency Noise Attenuation: GE IS200HFPAG2ADC targets and reduces high-frequency EMI (200kHz–1GHz) from nearby motors, generators, and power cables—common in turbine halls—by 40dB. This prevents signal corruption in sensitive circuits like excitation voltage sensors, avoiding false turbine trips. A European combined-cycle plant reported a 90% reduction in EMI-related alarms after installing GE IS200HFPAG2ADC, eliminating 2 annual unplanned shutdowns.

Wide Compatibility with IS200 Series: GE IS200HFPAG2ADC seamlessly integrates with GE’s IS200 series power and excitation modules, including GE IS200TPSAG1A (redundant power supply) and GE IS200EPDMG1ABA (exciter power distribution). It requires no custom adapters, reducing installation time by 30% compared to third-party filters that need modification for Mark VI/VIe compatibility.

Robust Surge and Overcurrent Protection: Beyond filtering, GE IS200HFPAG2ADC includes a 15A thermal fuse for overcurrent protection and 6kV ESD surge protection, safeguarding connected modules from voltage spikes. This dual protection reduces component replacement costs by 25% compared to filters lacking integrated safeguards.

Compact, Space-Saving Design: Packed into a 1U rack-mount form factor, GE IS200HFPAG2ADC fits alongside existing IS200 modules in control cabinets, eliminating the need for additional shelf space. Its lightweight construction (0.9kg) simplifies handling during installation and maintenance.

Application Field

GE IS200HFPAG2ADC is indispensable in industries where high-frequency EMI threatens turbine control system performance, with key applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200HFPAG2ADC protects gas/steam turbine excitation circuits from EMI generated by large generators and transformers. A 450MW combined-cycle plant in the Southern U.S. used GE IS200HFPAG2ADC to filter power for its EX2100 excitation regulator, resolving persistent voltage sensor noise that caused intermittent load fluctuations—improving grid compliance and cutting penalty fees by $60,000 annually.

In the oil & gas sector, GE IS200HFPAG2ADC shields offshore platform turbine controls from EMI caused by radar systems and subsea cables. A North Sea platform deployed GE IS200HFPAG2ADC to protect its GE IS200EROCH1ADD module, preventing false ground fault alarms during storm-induced electrical noise and avoiding a $280,000 compressor shutdown.

In petrochemical facilities, GE IS200HFPAG2ADC filters power for turbine-driven pump controls, where EMI from nearby process pumps disrupts pressure sensor signals. A Gulf Coast refinery reported a 35% reduction in pump control errors after adopting GE IS200HFPAG2ADC, streamlining reactor feedstock delivery and reducing product defects.

Related Products

GE IS200TPSAG1A: Redundant power supply that feeds 24V DC to GE IS200HFPAG2ADC, ensuring stable input power for filtering.

GE IS200EPSMG1ABB: Exciter power supply module that receives filtered power from GE IS200HFPAG2ADC, maintaining stable output for the EX2100 regulator.

GE IS200EPDMG1ABA: Exciter power distribution module paired with GE IS200HFPAG2ADC to filter power for multiple exciter components.

GE IS200TBCIH1B: Mixed-signal terminal board that benefits from GE IS200HFPAG2ADC’s noise filtering, ensuring clean sensor signals to the Mark VI/VIe controller.

GE IS200EROCH1ADD: Exciter regulator options card that relies on GE IS200HFPAG2ADC to eliminate EMI, preventing false ground fault detections.

GE IS200HFPAG1ABC: Predecessor model of GE IS200HFPAG2ADC with lower frequency range (100kHz–500MHz); upgraded for broader EMI coverage.

GE IC660HHM501: Handheld monitor used to test EMI attenuation levels of GE IS200HFPAG2ADC, validating filter performance on-site.

IS200HFPAG2ADC

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200HFPAG2ADC, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and verify that the input power supply (e.g., GE IS200TPSAG1A) meets the 18–30V DC range. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s filtering components, and use shielded twisted-pair cables for input/output connections to maximize EMI reduction. Label cables to match GE IS200HFPAG2ADC’s terminal markings (e.g., “IN-PRIMARY” for primary power input) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200HFPAG2ADC to check for loose terminal blocks, corrosion on connectors, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module’s shielding enclosure, avoiding direct airflow on internal components. Quarterly, test EMI attenuation using a spectrum analyzer to ensure performance remains at ≥35dB (100MHz); replace the module if attenuation drops below this threshold. If a fault is detected (red LED), power down the associated power circuit before removing GE IS200HFPAG2ADC—always use a factory-calibrated unit to maintain filtering accuracy.

Product Guarantee

GE guarantees the performance and reliability of GE IS200HFPAG2ADC with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe EMI mitigation and can assist with filter configuration, performance testing, and integration of GE IS200HFPAG2ADC. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200HFPAG2ADC’s EMI attenuation, surge protection, and compatibility with IS200 series modules. Additionally, GE provides repair services for GE IS200HFPAG2ADC, including functional testing of filtering circuits in an OEM-approved environment to restore the module to factory specifications—ensuring long-term power quality in industrial automation systems.