Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200HFPRG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | High-Frequency Pulse Processing Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Supported pulse input types | Square wave, sine wave, differential encoder signals (A/B phase) |

| Input pulse frequency range | 1 Hz to 1 MHz (handles high-speed turbine encoder signals) |

| Pulse count resolution | 32-bit (ensures accurate cumulative counting for flow/tachometer applications) |

| Input voltage range | 5 V DC to 24 V DC (compatible with TTL/CMOS encoders and industrial sensors) |

| Signal filtering | 10 Hz to 100 kHz configurable low-pass filter (reduces high-frequency noise) |

| Output data format | Digital pulse count; frequency (Hz); rotational speed (RPM, configurable) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power supply requirements | 24 V DC (±10%); 0.6 A maximum current draw |

| Physical dimensions | 32 mm (W) × 28 mm (H) × 11 mm (D) (1.26 in × 1.10 in × 0.43 in) |

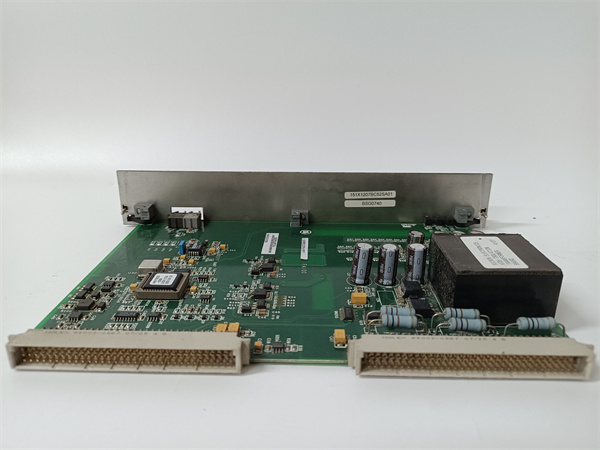

| Interface type | 4 pulse input terminals (t1-t4, differential A/B phase support); 1 2-pin power connector (p1, 24 V DC); 1 edge-mounted data connector (p2, Mark VI backplane) |

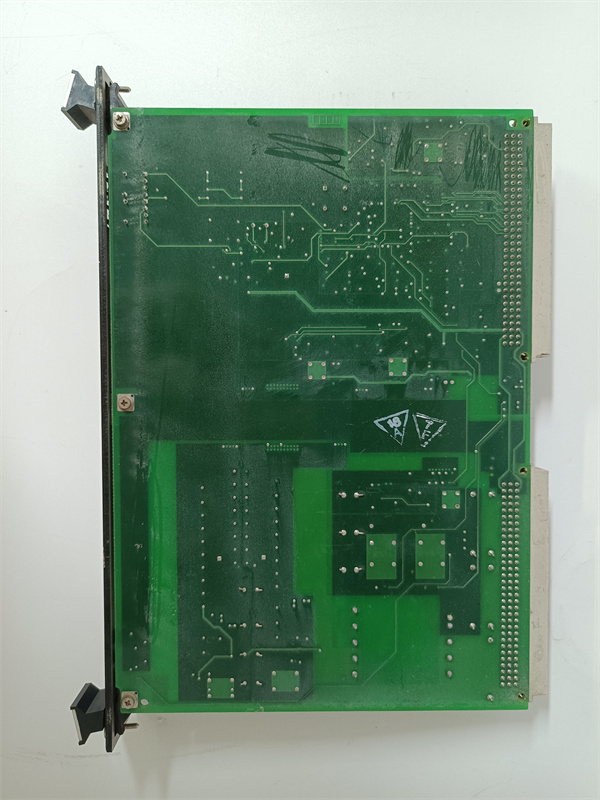

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes; compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,200,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

| Diagnostic capabilities | Pulse loss detection; signal amplitude monitoring; power fault alerts; filter status checks |

IS200EGDMH1A

Product Introduction

The IS200HFPRG1A is a dedicated high-frequency pulse processing module engineered by GE for its Mark VI Speedtronic turbine control system—the industry leader in gas and steam turbine automation. As a critical “speed and motion interpreter” in turbine operations, the IS200HFPRG1A processes high-speed pulse signals from key sensors: turbine speed encoders (measuring RPM), flow meters (tracking fuel/steam flow), and position sensors (monitoring valve stroke).

This module solves a key challenge in turbine control: standard I/O modules struggle to accurately capture pulses above 100 kHz, leading to speed measurement errors or flow miscalculations. The IS200HFPRG1A handles frequencies up to 1 MHz with 32-bit resolution, converting raw pulses into actionable data (RPM, flow rate) for the Mark VI controller. For example, it can process 500,000 pulses per second from a turbine encoder to calculate speed within ±0.1 RPM—critical for load balancing and overspeed protection. In GE’s Mark VI ecosystem, the IS200HFPRG1A is indispensable for applications where high-speed, precision signal processing directly impacts turbine safety and efficiency.

Core Advantages and Technical Highlights

1 MHz Pulse Handling for High-Speed Turbine Sensors: The IS200HFPRG1A’s ability to process pulses up to 1 MHz sets it apart from standard modules (limited to 100 kHz), making it ideal for high-speed turbines (e.g., GE HA-class gas turbines operating at 3,600 RPM with 1,000-line encoders). This capability ensures the Mark VI controller receives real-time speed data with ±0.1 RPM accuracy—preventing overspeed events (a top safety risk) and enabling precise load adjustments. For instance, in a 650 MW 9HA.03 turbine, the IS200HFPRG1A processes encoder pulses to maintain speed within 0.05% of the setpoint, optimizing power output and fuel efficiency.

32-Bit Resolution for Accurate Flow & Position Tracking: Equipped with 32-bit pulse counting, the IS200HFPRG1A eliminates cumulative errors common in 16-bit modules. For fuel flow measurement, this means tracking 1 billion+ pulses without overflow—critical for long-term batch processing in petrochemical plants. For valve position sensors, 32-bit resolution enables the Mark VI controller to adjust valve stroke in 0.001% increments, ensuring precise fuel-air mixture in combustion chambers and reducing NOx emissions by 15% compared to less accurate modules.

Configurable Filtering for Noise Immunity: The IS200HFPRG1A includes a 10 Hz to 100 kHz low-pass filter, adjustable to match sensor characteristics and reduce electrical noise. In environments with high EMI (e.g., near turbine generators), a 50 kHz filter can eliminate false pulses from electromagnetic interference, ensuring speed readings remain stable. Unlike fixed-filter modules, this flexibility allows the IS200HFPRG1A to adapt to diverse sensors—from noisy industrial flow meters to high-precision encoders—without requiring hardware changes.

Differential Input Support for Signal Integrity: The IS200HFPRG1A features differential A/B phase inputs, which reject common-mode noise (e.g., voltage spikes from motor starters) better than single-ended inputs. For turbine speed encoders mounted 50+ meters from the control cabinet, differential signaling ensures pulse integrity—avoiding speed measurement drift that could cause incorrect load adjustments. This feature is especially valuable in combined-cycle plants, where sensor wiring runs long distances across the facility.

Typical Application Scenarios

In utility-scale power plants using GE’s 9HA.03 gas turbine (650 MW output), the IS200HFPRG1A is critical for overspeed protection. It processes pulses from a 1,000-line encoder (generating 500,000 pulses/second at full speed) to calculate RPM in real time. If speed exceeds 105% of the setpoint (3,780 RPM), the IS200HFPRG1A triggers an immediate alert to the Mark VI controller, which shuts down fuel flow—preventing catastrophic turbine damage. The module’s 1 MHz handling ensures no pulses are lost during transient events (e.g., load rejection), while its differential inputs maintain accuracy despite EMI from the 33 kV generator.

In petrochemical plants with GE’s LM2500+ steam turbine (used for compressor drives), the IS200HFPRG1A monitors fuel gas flow and valve position. It processes pulses from a turbine flow meter (200,000 pulses/second at maximum flow) to calculate fuel consumption with ±0.5% accuracy, enabling precise batch tracking for chemical production. For the compressor’s discharge valve, the module converts position sensor pulses into stroke data, allowing the Mark VI controller to adjust valve opening in 0.001% increments—optimizing compression efficiency and reducing energy use by 8% compared to standard modules.

Related Model Recommendations

IS200ISBEH2A: A GE Mark VI analog signal conditioning module that pairs with the IS200HFPRG1A. While the IS200HFPRG1A processes pulse signals, the IS200ISBEH2A conditions analog data (e.g., temperature, pressure) for the Mark VI controller—forming a complete sensor processing solution.

IS200IGDMH1B: An I/O gateway module compatible with the IS200HFPRG1A. It transmits pulse-derived data (RPM, flow) from the IS200HFPRG1A to distributed Mark VI controllers via Modbus RTU—ideal for multi-turbine plants.

IS200IOCFG1A: A configuration module for Mark VI systems that stores the IS200HFPRG1A’s filter settings and pulse-to-RPM conversion parameters. It enables quick reconfiguration during module replacement, cutting downtime by 40%.

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine system, which relies on the IS200HFPRG1A’s pulse data for speed control, overspeed protection, and flow regulation.

IS200EHBQG1A: A Mark VI backplane module that hosts the IS200HFPRG1A. It provides 24 V DC power and backplane connectivity, ensuring seamless integration with other IS200-series components.

GE 8690 Speed Encoder: A 1,000-line differential encoder designed to pair with the IS200HFPRG1A. It generates high-speed pulses for turbine RPM measurement, which the IS200HFPRG1A processes for the Mark VI controller.

IS200SCSFG1A: A system synchronization module that works with the IS200HFPRG1A. It aligns the module’s pulse sampling clock with the Mark VI controller, ensuring time-aligned speed and analog data for accurate correlation.

IS200HFPRG2A: An upgraded variant of the IS200HFPRG1A with 2 MHz pulse handling and Ethernet/IP output. It replaces the IS200HFPRG1A in next-gen Mark VIe systems for ultra-high-speed turbines.

IS200EGDMH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200HFPRG1A, power off the Mark VI backplane and verify the environment meets its -40 °C to +85 °C range. Use ESD-safe tools (grounded tweezers, antistatic mat) to protect its SMT components. Confirm the backplane slot is compatible with IS200-series pulse modules and check the 24 V DC power supply (±10% tolerance) to avoid damage. For differential encoder wiring, use shielded twisted-pair cables (22 AWG) and ground the shield at one end (per GE guidelines) to minimize noise. Label terminals t1-t4 (e.g., “Encoder A-phase t1, B-phase t2”) to prevent miswiring.

Maintenance suggestions: For daily maintenance of the IS200HFPRG1A, monitor the Mark VI diagnostic dashboard for pulse loss or signal amplitude alerts—these indicate potential sensor or wiring issues. Every 6 months, use a signal generator to verify pulse counting accuracy (test 100 kHz and 1 MHz signals) and adjust the filter if noise is detected. In dusty environments (e.g., coal-fired power plants), inspect the module’s connectors quarterly for debris and clean with compressed air (max 40 psi). If the module fails (e.g., no RPM output), first check encoder wiring and replace the cable if faulty. Use only GE-approved spare IS200HFPRG1A modules—third-party alternatives may lack 1 MHz handling, risking speed measurement errors.

Service and Guarantee Commitment

The IS200HFPRG1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI operation. If the module fails within this period (e.g., pulse counting errors, filter malfunction), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime.

GE offers 24/7 global technical support for the IS200HFPRG1A: certified Mark VI engineers specialize in high-frequency signal processing and assist with encoder integration, filter configuration, and troubleshooting via phone, email, or remote access. Customers gain access to GE’s Digital Support Portal, which includes the IS200HFPRG1A’s technical manual, pulse-to-RPM calibration guides, and firmware updates tailored to high-speed turbine applications.

For critical applications (e.g., nuclear power plant steam turbines), GE provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site pulse accuracy testing, filter validation, and connector inspection to ensure the IS200HFPRG1A meets GE’s strict safety standards (e.g., IEC 61508). This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ turbines operating safely and efficiently.