Description

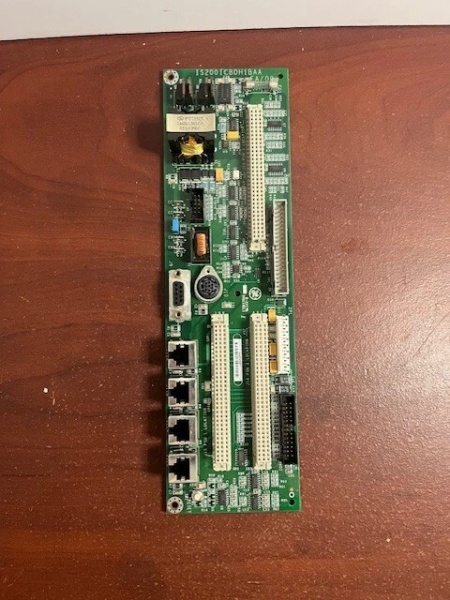

GE IS200ICBDH1B Mark VIe Enhanced Intelligent Control I/O Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS200ICBDH1B** Manufacturer | GE General Electric Product Category | Industrial Enhanced Intelligent Control I/O Module Series | Mark VIe (Turbine Control System) Core Function | High-precision Signal Acquisition, Redundant Control Output, Fault Self-diagnosis Analog Input (AI) | 12 Channels, 4-20mA/0-10V/RTD, 24-bit Resolution Analog Output (AO) | 6 Channels, 4-20mA/0-10V, 18-bit Resolution, Redundant Output Optional Digital Input (DI) | 24 Channels, Dry Contact/NPN/PNP, 24V DC, Debounce Adjustable Digital Output (DO) | 12 Channels, Relay/Transistor, 24V DC/250V AC, Force Output Function Communication Interface | 2×GE SRTP Ethernet (Redundant), 1×RS485 (MODBUS RTU/TCP) Data Refresh Rate | 0.5ms/Channel (Analog), 0.2ms/Channel (Digital) Isolation Voltage | 3000V AC (Channel to Channel, Channel to Power, Communication) Operating Temperature | -25°C to 75°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 4X (Terminal Block Standard) Physical Dimensions | 140mm × 120mm × 35mm Certifications | CE, UL 508, IEC 61508 (SIL 3), ATEX Zone 2 Power Supply | 24V DC ±15%, 2.0A Max

Product Introduction

The **GE IS200ICBDH1B** is an enhanced high-reliability intelligent control I/O module customized for GE’s Mark VIe turbine control system, acting as the “core signal processing node” in the critical control loop of the turbine control system. Different from basic I/O modules, this module is specially developed for the key control links of large thermal power, nuclear power auxiliary turbines, and high-power industrial turbines, realizing high-precision acquisition of multi-type field signals (including temperature, pressure, flow, and thermal resistance signals), redundant and reliable control output of actuators, and real-time fault self-diagnosis. It integrates more I/O channels in the same physical size, supports dual redundant GE SRTP Ethernet communication, and has built-in advanced signal processing algorithms to suppress complex interference in harsh environments. With SIL 3 safety certification and ATEX explosion-proof grade, it is an irreplaceable core component for turbine control systems with strict requirements on safety, reliability, and precision.

What makes the **GE IS200ICBDH1B** stand out is its 24-bit high-resolution signal acquisition, full-link redundant design, and SIL 3 safety performance—advantages that perfectly meet the core needs of critical turbine control links for “zero error” signal processing and “non-stop” control. Adopting GE’s fourth-generation signal processing chip and dual-core redundant processing architecture, the module realizes dual-channel verification of key signals, and the acquisition error of analog signals is controlled within ±0.005%, which can capture tiny changes in turbine bearing temperature (0.01°C) and steam pressure (0.001MPa). The digital channels with 0.2ms ultra-fast response can capture the turbine overspeed signal and trigger the emergency stop output within 1ms, effectively avoiding safety accidents. Equipped with 3000V AC three-level reinforced isolation and built-in surge protection circuit, it can resist 4kV transient overvoltage interference from the turbine power system. The dual redundant Ethernet interface ensures that the communication link is not interrupted, and the optional AO channel redundant output further improves the reliability of the control loop. By building a “safe and reliable signal barrier” between the Mark VIe controller and field equipment, it provides the highest level of guarantee for the safe operation of large turbines.

Core Advantages and Technical Highlights

24-bit High-precision Multi-type Signal Acquisition: The **IS200ICBDH1B** is equipped with 12 AI channels supporting three signal types (4-20mA, 0-10V, RTD), with 24-bit resolution and acquisition error ≤±0.005%. The AI channels adopt differential input + signal preprocessing technology, which can directly connect to turbine bearing RTD temperature sensors (Pt100/Pt1000), high-precision steam pressure transmitters, and ultra-low flow meters. The built-in cold junction compensation function for RTD signals ensures that the temperature measurement error is within ±0.1°C. For example, when monitoring the turbine high-pressure rotor bearing temperature, the module can accurately collect the Pt100 sensor signal, convert it into digital data with 0.01°C resolution, and transmit it to the Mark VIe controller, providing a reliable basis for the turbine’s thermal state monitoring and fault early warning.

Redundant Output and Ultra-fast Digital Control: The module integrates 24 DI channels and 12 DO channels, with comprehensive enhancement in function and performance. The DI channels support dry contact, NPN, and PNP three input modes, and the debounce time can be adjusted between 10μs-10ms via software, which is suitable for collecting different types of switch signals such as turbine emergency stop buttons, speed measuring gear teeth, and valve position feedback. The response time is as fast as 0.2ms, ensuring that the overspeed signal (≥3300r/min for 3000r/min turbine) is captured and uploaded within 0.5ms. The 12 DO channels provide relay and high-power transistor output options, the relay output supports 250V AC/30A high load, and the transistor output supports 10kHz high-frequency switching. Key AO/DO channels support redundant output configuration, and when the main channel fails, it can automatically switch to the standby channel within 1ms, ensuring the continuity of the turbine control loop.

Dual Redundant Communication and Advanced Self-diagnosis: The **IS200ICBDH1B** is equipped with two independent GE SRTP Ethernet interfaces, forming a dual redundant communication network with the Mark VIe controller, and the communication delay is ≤0.5ms. The built-in RS485 interface supports both MODBUS RTU and TCP protocols, which can connect to third-party safety monitoring equipment and realize data synchronization without protocol conversion. The module has a full-link self-diagnosis function, which can perform real-time detection on power supply, signal acquisition circuit, output drive circuit, and communication interface. When a fault (such as channel drift, output short circuit) occurs, it can locate the fault point to the specific channel within 100μs, send a fault code to the controller, and trigger the local alarm indicator. It supports online calibration and firmware update without power-off, and the calibration data is stored in non-volatile memory to avoid data loss after power failure.

Reinforced Isolation and Multi-environment Adaptability: The module adopts a four-level reinforced isolation design (channel-channel, channel-power, communication-internal circuit, power-ground) with an isolation voltage of 3000V AC, which can effectively suppress common-mode interference up to 2kV and differential-mode interference up to 1kV, ensuring signal integrity in the complex electromagnetic environment of large turbine generator sets. It meets the IEC 61508 SIL 3 safety standard and ATEX Zone 2 explosion-proof grade, and can be used in safety-related control loops (such as turbine overspeed protection, emergency shutdown) and hazardous areas such as gas turbine workshops. The operating temperature range of -25°C to 75°C and the standard NEMA 4X terminal block enable it to adapt to extreme working environments such as alpine hydropower plants, high-temperature boiler rooms, and coastal salt-mist areas. The metal shell with anti-vibration and anti-shock design meets the IEC 60068-2-27 standard, and can withstand the vibration and impact generated by the turbine startup and shutdown process.

IS200ICBDH1A

Typical Application Scenarios

In large thermal power plant 600MW steam turbine main control systems, the **IS200ICBDH1B** serves as the core I/O module for the critical control loop. It configures 8 AI channels to connect the turbine high/low pressure cylinder temperature RTD sensors, main/reheat steam pressure transmitters, and bearing vibration transmitters, 4 AI channels to connect the oil pressure and oil temperature sensors, 12 DI channels to connect the overspeed switch, emergency stop button, and valve position limit switches, and 6 DO channels (3 groups of redundant output) to control the main steam valve, reheat steam valve, and emergency shutdown solenoid valve. The module collects the main steam pressure signal with 24-bit resolution, and the data refresh rate reaches 0.5ms. When the pressure exceeds 17MPa (set threshold), the Mark VIe controller sends a control command, and the module outputs a precise 4-20mA signal through the redundant AO channel to adjust the main steam valve opening, realizing the closed-loop control of steam pressure with ±0.01MPa precision. The SIL 3 certification ensures that the control loop has a fault tolerance rate of ≥99.99%.

In nuclear power plant auxiliary turbine control systems (such as feedwater pump turbines), the **IS200ICBDH1B** undertakes the signal acquisition and safety control tasks. It uses 6 AI channels to collect the turbine speed, water head, flow, and guide vane opening signals, 6 AI channels to connect the bearing temperature RTD sensors and lubricating oil pressure transmitters, 16 DI channels to collect the guide vane limit switch status, pressure switch status, and emergency stop signal, and 8 DO channels (4 groups of redundant output) to control the guide vane electro-hydraulic actuator, oil pump, and safety solenoid valve. The module’s dual redundant Ethernet interface ensures that the communication with the Mark VIe controller is not interrupted, and the 0.2ms fast-response DI channel can capture the turbine overspeed signal (≥6300r/min for 6000r/min turbine) and trigger the emergency shutdown output within 1ms. The ATEX explosion-proof grade makes it suitable for the harsh environment of the nuclear power plant auxiliary workshop, and the 3000V AC isolation effectively resists the electromagnetic interference from the nuclear power plant’s high-voltage equipment.

In large-scale industrial gas turbine control systems (such as 100MW heavy-duty gas turbines), the **IS200ICBDH1B** realizes the centralized control of the fuel system, combustion system, and cooling system. It connects 5 AI channels to the fuel pressure, fuel temperature, and combustion chamber temperature sensors, 7 AI channels to the cooling water temperature, air pressure, and turbine exhaust temperature transmitters, 20 DI channels to the fuel filter blockage switch, flame detector status, and valve position feedback signals, and 12 DO channels to control the fuel solenoid valve, ignition device, and cooling water pump. The module’s MODBUS TCP interface connects to the plant-level safety monitoring system to realize real-time data upload. When the combustion chamber temperature exceeds 1500°C, the DI channel detects the flame detector signal and transmits it to the controller within 0.3ms. The controller immediately sends a command, and the module’s redundant DO channel cuts off the fuel supply and starts the emergency cooling system, avoiding gas turbine burnout. The SIL 3 safety performance ensures that the fault response process has no false actions or missed actions.

Related Model Recommendations

**IS200ICBDH2B**: Ultra-high-channel variant of **IS200ICBDH1B**, 16 AI/8 AO/32 DI/16 DO, supporting triple redundant output, suitable for super-large turbine control systems such as nuclear power main turbines.

**IS200MACCH2B**: Triple redundant Mark VIe controller matched with **IS200ICBDH1B**, realizing 1oo2D safety control logic for critical control loops.

**IS200RAPAG2BCA**: Triple-channel redundant power supply module for **IS200ICBDH1B**, supporting 24V DC/110V DC dual input, ensuring power supply reliability in extreme scenarios.

**GE 3500/42M Vibration Transmitter**: High-temperature vibration sensor matched with **IS200ICBDH1B**, outputting 4-20mA signal, suitable for turbine high-temperature bearing vibration monitoring.

**IC754VSI24CTD**: Safety-level HMI matched with **IS200ICBDH1B**, supporting SIL 2 safety certification, displaying real-time I/O data and fault diagnosis results.

**GE Proficy PlantApps**: Asset performance management software connected with **IS200ICBDH1B**, realizing predictive maintenance based on I/O signal trend analysis.

**IS200NIOBG2A**: Mark VIe dual redundant network interface module for **IS200ICBDH1B**, supporting Ethernet ring network topology and improving network reliability.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS200ICBDH1B**, power off the Mark VIe control cabinet and field equipment, and confirm the module slot is compatible with the redundant backplane (reserve ≥8cm heat dissipation space). Use double-shielded twisted-pair cables for AI/AO channel wiring, and the inner shield is grounded at the sensor end, and the outer shield is grounded at the control cabinet end. DI/DO channels use flame-retardant shielded cables, and the shield layer is single-point grounded. Connect the dual Ethernet interfaces to the A/B networks of the Mark VIe system respectively, and set the IP address and communication parameters via the DIP switch and software. Perform insulation resistance testing (channel to ground ≥1000MΩ at 500V DC) and loop resistance testing for RTD channels before power-on. Use a standard signal generator to perform pre-calibration on the AI/AO channels, and record the calibration data in the system.

Maintenance suggestions: Conduct 24-hour real-time monitoring of the module’s I/O data, communication status, and self-diagnosis results via the Mark VIe system, and set up automatic alarms for abnormal signals (such as channel drift exceeding ±0.01%). Perform bi-monthly on-site inspections: use a thermal imager to detect the module’s temperature distribution (no local overheating), check the tightness of the terminal block (torque ≥1.2N·m), and clean the dust with compressed air (pressure ≤0.3MPa). Calibrate the AI channels monthly using a high-precision signal calibrator (accuracy ≥0.001%) and verify the redundant output function of the AO/DO channels. Back up the module configuration parameters and calibration data weekly, and store them in a secure server. When a fault occurs, use the system’s fault diagnosis function to locate the fault point, and replace the module with a pre-calibrated spare module (supporting hot swapping). Update the firmware quarterly under the guidance of GE technical personnel to ensure the module’s safety performance is up to standard.

Service and Guarantee Commitment

GE General Electric provides a 60-month quality guarantee for the **IS200ICBDH1B**, covering manufacturing defects, channel failure, communication abnormality, isolation performance degradation, and calibration data drift under normal operating conditions. Our professional safety technical team provides 24×7 on-site and remote support, including safety loop debugging, fault diagnosis, and SIL 3 certification guidance. Customers can obtain the module’s safety manual, calibration procedure, and explosion-proof certification document for free. For key projects such as nuclear power and large thermal power, we provide on-site resident technical support during the commissioning period and spare parts localization storage services to ensure that faulty modules are replaced within 4 hours. We also offer customized SIL safety training courses to help customers’ maintenance personnel master the safety operation specifications of the module and ensure the long-term safe and reliable operation of the turbine control system.