Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

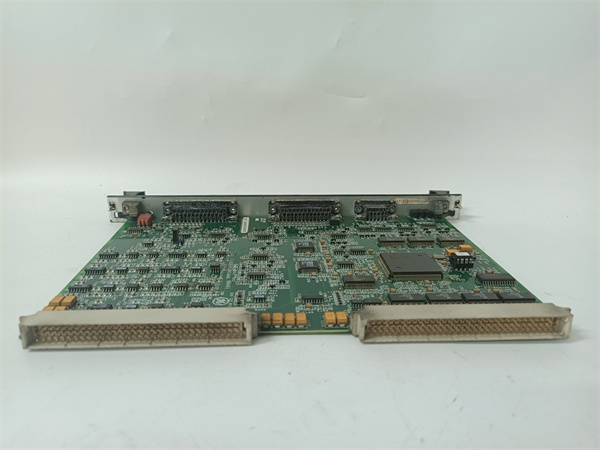

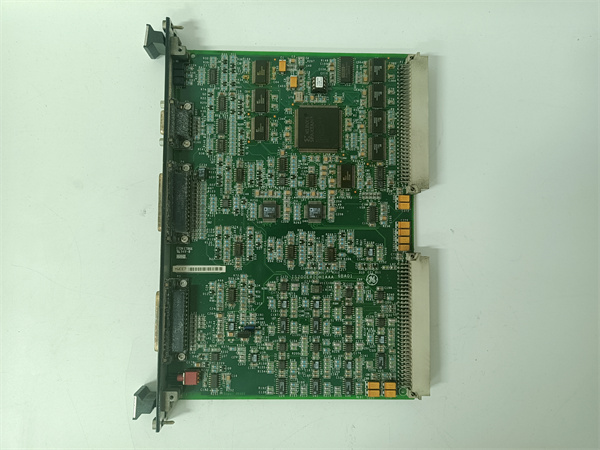

| Product model | IS200ISBAH1A |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Division) |

| Product category | High-Precision Analog Input Module (for Ovation DCS Process Monitoring) |

| Input channel count | 8 differential analog input channels (configurable per channel) |

| Supported input signal types | 4-20 mA DC; 0-20 mA DC; 0-5 V DC; 0-10 V DC; RTD (Pt100, Pt1000); Thermocouple (J, K, T, E, R, S, B) |

| Input accuracy | ±0.05% full scale (for 4-20 mA/0-10 V); ±0.1% full scale (for RTD/thermocouple) |

| Resolution | 24-bit A/D conversion (for all signal types) |

| Sampling rate | 10 samples per second (per channel); configurable up to 100 samples/sec (burst mode) |

| Communication protocol | Ovation Control Network (OCN); Redundant data bus support (A/B channels) |

| Operating temperature range | 0 °C to 60 °C (32 °F to 140 °F); -40 °C to 70 °C (storage) |

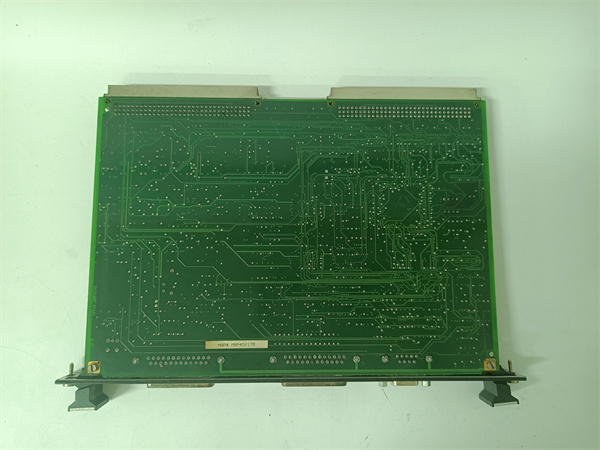

| Physical dimensions | 165 mm (W) × 102 mm (H) × 229 mm (D) (6.50 in × 4.02 in × 9.02 in) |

| Installation method | Ovation 3U I/O chassis mounting (compatible with IS200-series I/O racks) |

| Power supply requirements | 5 V DC (±5%); 1.1 A maximum current draw; Powered via Ovation chassis backplane |

| Protection features | Channel-level overvoltage protection (up to 36 V DC); ESD protection (15 kV contact); Short-circuit protection |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 1,900,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Diagnostic capabilities | Channel open/short detection; A/D conversion error logging; Sensor drift alerts; Power fault monitoring |

| Weight | 450 g (0.99 lb) |

IS200ERIOH1A

Product Introduction

The IS200ISBAH1A is a high-precision analog input module from Emerson’s Ovation distributed control system (DCS) portfolio, designed to serve as the “analog signal hub” for industrial process monitoring. As a core I/O component of the Ovation platform, the IS200ISBAH1A supports a wide range of analog signals—including current (4-20 mA), voltage (0-10 V), RTDs, and thermocouples—enabling it to connect to nearly any analog sensor in a plant. This versatility eliminates the need for multiple specialized modules, simplifying system architecture and reducing hardware costs.

This module converts real-world physical parameters (e.g., reactor temperature, pipeline pressure, water flow rate) into digital data via 24-bit A/D conversion—delivering industry-leading accuracy (±0.05% full scale) that is critical for tight process control. For example, the IS200ISBAH1A can collect temperature data from a Pt100 RTD in a chemical reactor and transmit it to the Ovation controller with ±0.1% accuracy, ensuring the controller maintains temperatures within 0.1 °C of the setpoint. Its redundant OCN communication and channel-level protection features guarantee reliable data transmission even in electrically noisy or harsh industrial environments, making the IS200ISBAH1A indispensable for power generation, chemical processing, and water treatment industries.

Core Advantages and Technical Highlights

Multi-Signal Support for Versatile Sensor Integration: The IS200ISBAH1A stands out by supporting six major analog signal types—4-20 mA, 0-20 mA, 0-5 V, 0-10 V, RTDs, and thermocouples—all configurable per channel. This means a single IS200ISBAH1A module can connect to a 4-20 mA flow sensor, a Pt100 RTD temperature sensor, and a K-type thermocouple simultaneously. Unlike modules limited to one or two signal types, this versatility reduces the number of modules needed in a control cabinet by up to 60%, cutting hardware and installation costs while simplifying inventory management.

24-Bit Resolution & Ultra-High Accuracy: Equipped with 24-bit A/D conversion, the IS200ISBAH1A delivers unmatched precision for analog signals. Its ±0.05% full-scale accuracy for current/voltage signals ensures that even small changes in process variables (e.g., a 0.02 mA shift in a 4-20 mA flow signal) are detected—critical for applications like pharmaceutical batch processing, where minute deviations can affect product quality. For RTD/thermocouple signals, ±0.1% accuracy translates to temperature measurements within 0.1 °C of the true value, enabling precise control of heating/cooling systems in food and beverage manufacturing.

Configurable Sampling Rates for Dynamic Processes: The IS200ISBAH1A offers flexible sampling rates—10 samples per second (standard) and up to 100 samples per second (burst mode)—to adapt to dynamic or static processes. In fast-changing applications (e.g., steam pressure in a power plant boiler), burst mode captures rapid signal fluctuations, ensuring the Ovation controller receives real-time data to adjust control actions. In slower processes (e.g., tank level monitoring), standard sampling conserves bandwidth, reducing network traffic and improving overall DCS performance. This adaptability makes the IS200ISBAH1A suitable for both fast-paced and steady-state industrial operations.

Channel-Level Diagnostics & Protection: The IS200ISBAH1A includes robust channel-level diagnostics that detect open circuits (e.g., a broken wire to a thermocouple), short circuits (e.g., water damage causing signal shorting), and A/D conversion errors. Alerts are sent directly to the Ovation HMI, enabling technicians to identify and resolve issues before they disrupt processes. Additionally, each channel features overvoltage protection (up to 36 V DC) and ESD protection (15 kV), preventing module damage from voltage spikes or static discharge—common in industrial environments with heavy machinery or variable frequency drives (VFDs).

Typical Application Scenarios

In combined-cycle power plants, the IS200ISBAH1A plays a critical role in boiler and turbine monitoring. It collects analog data from multiple sensors: 4-20 mA signals from steam flow meters, Pt100 RTDs from turbine bearing temperatures, and K-type thermocouples from boiler flue gas. The module’s 24-bit resolution and ±0.05% accuracy ensure the Ovation controller receives precise data to optimize fuel-air mixture and turbine speed—directly improving power generation efficiency by 1-2% and reducing emissions. Its redundant OCN communication also guarantees data transmission during peak load periods, preventing unplanned outages.

Chemical processing facilities use the IS200ISBAH1A to monitor batch reactor conditions. It connects to 0-10 V pH sensors (measuring reagent acidity), 4-20 mA pressure transducers (tracking reactor internal pressure), and RTDs (monitoring jacket temperature). The module’s configurable sampling rates adapt to the batch cycle: burst mode (100 samples/sec) is used during the exothermic reaction phase to capture rapid temperature spikes, while standard sampling is used during the cooling phase. The IS200ISBAH1A’s diagnostics alert operators to a faulty pH sensor wire before it causes incorrect reagent dosing—avoiding costly batch rejection and ensuring compliance with EPA regulations.

Municipal wastewater treatment plants rely on the IS200ISBAH1A to monitor water quality and treatment processes. It collects 4-20 mA signals from turbidity sensors (measuring water clarity), 0-5 V chlorine residual sensors (tracking disinfection levels), and Pt1000 RTDs (monitoring digestion tank temperatures). The module’s wide signal support eliminates the need for separate RTD and current input modules, saving cabinet space. Its overvoltage protection withstands electrical noise from nearby pump motors, ensuring consistent data collection—critical for maintaining water quality standards and avoiding fines for non-compliant effluent discharge.

Related Model Recommendations

IS200ISBOH1A: A sibling module of the IS200ISBAH1A with 8 analog output channels (vs. inputs), ideal for pairing with the IS200ISBAH1A to create a complete analog input-output loop—e.g., monitoring reactor pressure via IS200ISBAH1A and controlling a pressure relief valve via IS200ISBOH1A.

IS200SDIIH1A: Emerson’s high-density digital input module that complements the IS200ISBAH1A—the IS200ISBAH1A collects analog process data, while the IS200SDIIH1A handles discrete signals (e.g., valve position switches), forming a comprehensive I/O solution.

1C31234G01: Ovation’s main controller that communicates directly with the IS200ISBAH1A—the controller processes the module’s analog data and executes control logic (e.g., adjusting a valve based on flow rate readings).

IS200SCNVG1A: Ovation’s network gateway module that works with the IS200ISBAH1A—it translates the module’s analog data into Modbus TCP/IP or DNP3.0 for transmission to external SCADA systems (e.g., a utility’s remote monitoring platform).

IS200SSCAH2A: Ovation’s system synchronization module that integrates with the IS200ISBAH1A—it synchronizes the module’s sampling clock with other Ovation nodes, ensuring time-aligned data for accurate process correlation.

Emerson Rosemount 3051 Pressure Transmitter: A 4-20 mA pressure sensor designed to pair with the IS200ISBAH1A—it sends high-precision pressure data to the module, which transmits it to the Ovation DCS for process control.

IS200ISBAH2A: An upgraded variant of the IS200ISBAH1A with 16 analog input channels (vs. 8) and -40 °C to 70 °C operating range—suited for large-scale facilities (e.g., refineries) or extreme-temperature environments (e.g., arctic oil fields).

IS200TBAIH1B: A digital I/O module that complements the IS200ISBAH1A—it provides discrete inputs for equipment status (e.g., pump running/stopped) while the IS200ISBAH1A monitors analog process variables.

IS200ERIOH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200ISBAH1A, power off the Ovation 3U I/O chassis and verify it is grounded (minimum 4 mm² ground wire) to prevent electrical shock. Confirm the chassis slot is compatible with IS200-series modules and the environment meets the module’s operating range (0-60 °C, 10-90% non-condensing humidity). Required tools include a torque screwdriver (0.5-0.8 N·m for mounting), wire strippers (for 22-18 AWG sensor wires), and a precision signal generator (to calibrate input accuracy post-installation). Use shielded twisted-pair cables for sensor wiring (ground the shield at one end) to minimize EMI; label each channel (1-8) and its connected sensor (e.g., “Reactor Temp RTD”) to avoid misconfiguration.

Maintenance suggestions: For daily maintenance of the IS200ISBAH1A, check the module’s LED status lights (power: green; channel health: green = normal, red = fault; OCN communication: amber) during shift handovers—red LEDs indicate channel-level issues (e.g., open circuit) that require attention. Calibrate the module annually using a NIST-traceable signal generator to maintain ±0.05% accuracy; use Ovation Control Studio to adjust calibration offsets if needed. Every 3 months, clean the module’s vents with compressed air (max 40 psi) and inspect sensor wiring for tightness (re-torque terminal screws to 0.3 N·m if loose). If a channel fault occurs, use the Ovation HMI’s diagnostic tool to isolate the issue (e.g., short circuit on channel 5) before replacing wires or the IS200ISBAH1A. Use only Emerson-approved spare modules to ensure compatibility and accuracy.

Service and Guarantee Commitment

The IS200ISBAH1A comes with a 2-year standard warranty from Emerson Automation Solutions, covering defects in materials, workmanship, and performance under normal industrial use. If the module fails within this period (e.g., channel malfunction, accuracy drift beyond specifications), Emerson will repair or replace it free of charge, with expedited shipping (24-48 hours for regional warehouses) to minimize downtime—critical for processes where analog data loss disrupts control.

Emerson offers 24/7 global technical support for the IS200ISBAH1A: certified Ovation engineers specialize in analog signal troubleshooting and can assist with sensor integration, calibration, and diagnostic interpretation via phone, email, or remote access (Emerson Remote Support Portal). Customers gain access to the Ovation Knowledge Base, which includes the IS200ISBAH1A’s technical manual, calibration guides, firmware updates, and application notes (e.g., “Configuring Thermocouples in Ovation DCS”).

For mission-critical applications (e.g., nuclear power plant process monitoring, pharmaceutical batch control), Emerson provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site calibration, signal accuracy testing, and diagnostic validation to ensure the IS200ISBAH1A meets strict industry standards (e.g., FDA 21 CFR Part 11, NERC CIP). This commitment reflects Emerson’s confidence in the module’s reliability and its dedication to helping customers maintain precise, compliant process control.