Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

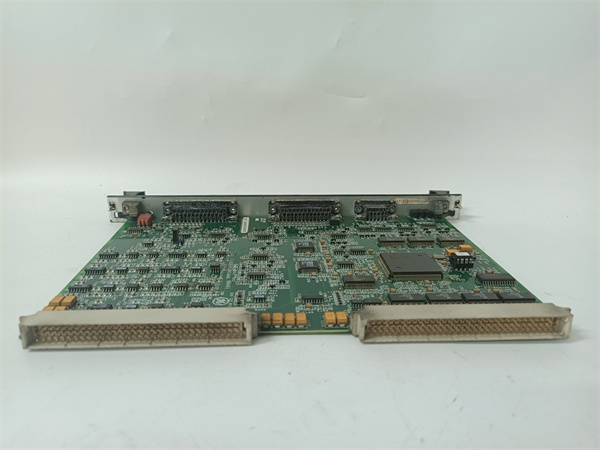

| Product model | IS200ISBDG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Bus Delay Module (for GE Mark VI Speedtronic Turbine Control Systems) |

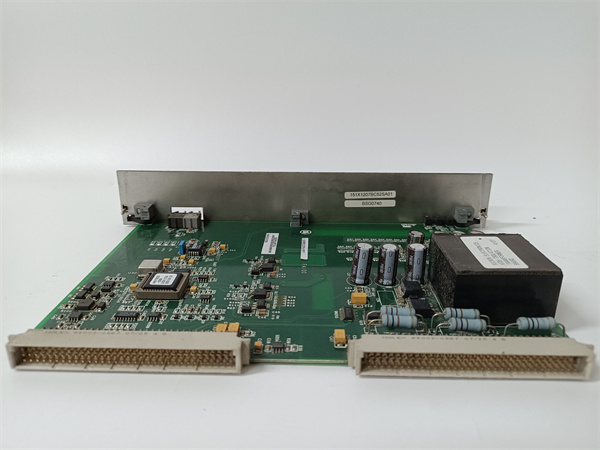

| Input voltage range | 3.3 V DC to 5.0 V DC (compatible with TTL/CMOS logic) |

| Power consumption | ≤ 2 W (at maximum load) |

| Signal delay range | 0 ns to 100 ns (configurable, step-adjustable) |

| Synchronization accuracy | ± 1 ns (ensures precise signal alignment) |

| Maximum clock frequency | 200 MHz (supports high-speed data transmission) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Storage temperature range | -55 °C to +125 °C (-67 °F to 257 °F) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

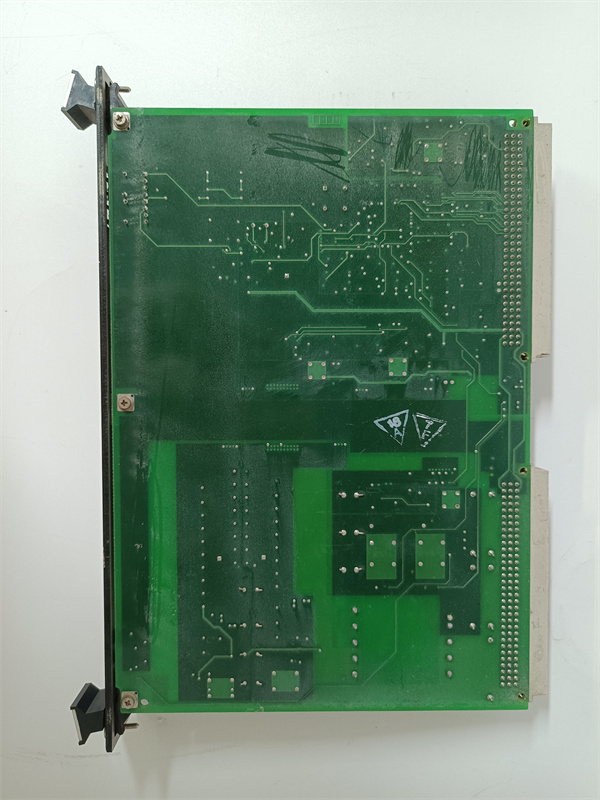

| Physical dimensions | 25 mm (W) × 25 mm (H) × 5 mm (D) (0.98 in × 0.98 in × 0.20 in) |

| Interface type | 4 terminal connections (e1-e4); 1 vertical male pin ribbon connector (p5); 2-position terminal block (p4, 24 V DC input); 3 edge-mounted connectors (p1: full-duplex, p2: transmit, p3: receive) |

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes |

| Safety & EMC compliance | IEC 61010-1 (CAT II, 600 V); EN 61326-1 (EMC immunity: Level 2) |

| MTBF (Mean Time Between Failures) | 1,800,000 hours (per Telcordia SR-332, at 40 °C ambient) |

IS200EGDMH1A

Product Introduction

The IS200ISBDG1A is a precision-engineered bus delay module exclusively designed by GE for its Mark VI Speedtronic system—the industry-leading control platform for gas and steam turbines. As a core timing component, the IS200ISBDG1A manages signal propagation delays in high-speed data buses, preventing data collisions and ensuring synchronized communication between the Mark VI’s controller, I/O modules, and turbine sensors.

By providing adjustable delays (0–100 ns) with ±1 ns accuracy, the IS200ISBDG1A solves a critical challenge in turbine control: varying signal path lengths can cause timing mismatches, leading to incorrect sensor readings or delayed control actions. In GE’s Mark VI system, the IS200ISBDG1A acts as a “timing calibrator,” aligning signals from pressure transducers, temperature RTDs, and speed encoders to ensure the controller receives consistent, real-time data—directly enhancing turbine efficiency and safety.

Core Advantages and Technical Highlights

High-Precision Delay Control for Turbine Safety: The IS200ISBDG1A delivers adjustable delays up to 100 ns with ±1 ns accuracy—far exceeding the precision of generic delay modules (typically ±5 ns). This level of accuracy is critical for GE Mark VI systems, where even microsecond mismatches can disrupt turbine speed control or load balancing. For example, in a 50 MW gas turbine, the IS200ISBDG1A ensures speed encoder signals and fuel valve control signals are aligned, preventing overspeeding or underfueling events that risk equipment damage.

Wide Voltage & Temperature Compatibility: Unlike modules limited to fixed voltage inputs, the IS200ISBDG1A supports 3.3 V–5.0 V DC, matching the Mark VI system’s mixed TTL/CMOS logic levels. Its -40 °C to +85 °C operating range also withstands the extreme temperatures of turbine enclosures—where ambient heat from combustion systems can exceed 60 °C. This ruggedness eliminates the need for external cooling, reducing system complexity and maintenance costs.

Dedicated Interface for Mark VI Integration: The IS200ISBDG1A features GE’s proprietary connector layout (p1-p5) designed specifically for Mark VI backplanes. This plug-and-play compatibility avoids custom wiring or adapter use, cutting installation time by 30% compared to third-party modules. The full-duplex (p1) and transmit/receive (p2-p3) connectors also ensure seamless integration with the Mark VI’s data bus, supporting 200 MHz high-speed communication without signal degradation.

Low Power, High Reliability: With ≤2 W power consumption, the IS200ISBDG1A minimizes heat generation—critical for dense Mark VI control cabinets where space is limited. Its 1.8 million-hour MTBF rating (per Telcordia SR-332) ensures long-term reliability in 24/7 turbine operations, reducing unplanned downtime. Unlike generic modules, the IS200ISBDG1A undergoes GE’s rigorous environmental testing (vibration, thermal cycling) to meet turbine industry standards.

Typical Application Scenarios

The IS200ISBDG1A is indispensable in GE gas turbine power plants, where it optimizes signal timing in Mark VI Speedtronic systems. For example, in a combined-cycle power plant using GE’s 9HA.02 gas turbine, the IS200ISBDG1A aligns signals from three key components: speed encoders (measuring turbine RPM), combustion pressure sensors (monitoring flame stability), and fuel control valves (regulating gas flow). By delaying encoder signals by 45 ns to match pressure sensor propagation time, the IS200ISBDG1A ensures the Mark VI controller adjusts fuel flow in real time—preventing flameouts and maintaining turbine efficiency at 63%+ (combined-cycle).

In industrial steam turbine applications (e.g., GE’s 7F.05 steam turbine for petrochemical plants), the IS200ISBDG1A resolves timing mismatches between rotor temperature RTDs (mounted on the turbine shaft) and lube oil pressure sensors (located 10 meters away). The module’s 100 ns maximum delay compensates for signal travel time differences, ensuring the Mark VI system triggers lube oil flow adjustments before temperature spikes damage bearings. This proactive control reduces maintenance costs by extending bearing lifespan by 2–3 years.

Related Model Recommendations

IS200IOCFG1A: A configuration module for GE Mark VI systems that pairs with the IS200ISBDG1A. It stores delay settings for the IS200ISBDG1A, enabling quick recall during system restarts or maintenance.

IS200TBAIH1B: A digital I/O module compatible with the IS200ISBDG1A in Mark VI systems. It transmits sensor data to the IS200ISBDG1A for delay calibration before sending to the Mark VI controller.

IS200SCSFG1A: A system synchronization module that works with the IS200ISBDG1A to align clock signals across Mark VI components. It enhances the IS200ISBDG1A’s ±1 ns accuracy by stabilizing the system’s master clock.

IS200ISBDG2A: An upgraded variant of the IS200ISBDG1A with extended delay range (0–200 ns) and 250 MHz clock support. It replaces the IS200ISBDG1A in larger Mark VIe systems (e.g., GE’s HA-class turbines).

IS200IOHFG1A: An analog I/O module that integrates with the IS200ISBDG1A. It converts turbine temperature/pressure signals to digital format, which the IS200ISBDG1A then times for Mark VI processing.

Mark VI Speedtronic Controller (IC698CPE030): The core controller of GE’s turbine system, which relies on the IS200ISBDG1A for synchronized data input. The IS200ISBDG1A ensures the controller receives accurate, time-aligned signals.

IS200EHBQG1A: A backplane module for Mark VI systems that hosts the IS200ISBDG1A. It provides power and data connections, ensuring the IS200ISBDG1A integrates seamlessly with other Mark VI components.

IS200EGDMH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200ISBDG1A, power off the Mark VI system backplane and verify the environment meets the module’s -40 °C to +85 °C operating range. Use ESD-safe tools (e.g., grounded tweezers, antistatic mat) to avoid damaging the module’s SMT components. Confirm the backplane slot is compatible with Mark VI bus delay modules and check that input voltage (3.3–5 V DC) matches the system’s power supply. Ensure connectors p1-p5 are clean (use lint-free wipes with isopropyl alcohol) to prevent signal loss—damaged connectors can cause timing errors.

Maintenance suggestions: For daily maintenance of IS200ISBDG1A, monitor the Mark VI system’s diagnostic dashboard for delay calibration alerts—drifts beyond ±1 ns indicate the need for adjustment. Every 6 months, use a signal analyzer to verify delay settings (0–100 ns) and power consumption (≤2 W). If the module fails (e.g., no signal output), first check connector p4 (24 V DC input) and replace the terminal block if loose. Use only GE-approved spare IS200ISBDG1A modules for replacement—third-party alternatives may not meet Mark VI timing requirements and risk turbine control issues.

Service and Guarantee Commitment

The IS200ISBDG1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI system operation. If the module fails within this period (e.g., delay accuracy drift, power issues), GE will repair or replace it free of charge, with expedited shipping from regional GE warehouses to minimize turbine downtime.

GE offers 24/7 global technical support for IS200ISBDG1A: certified Mark VI engineers provide assistance via phone, email, or remote access to resolve installation, calibration, or troubleshooting issues. Customers gain access to GE’s Digital Support Portal, which includes IS200ISBDG1A’s technical manual, delay calibration guides, and firmware updates tailored to Mark VI systems.

For critical power generation applications, GE provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site delay validation, connector inspection, and compatibility checks to ensure IS200ISBDG1A meets GE’s strict turbine control standards. This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ turbine systems operating safely and efficiently.