Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200ISBEH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Analog Signal Conditioning Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Input signal types | 4-20 mA DC (current); 0-10 V DC (voltage); RTD (Pt100, Pt1000); Thermocouple (J, K, T) |

| Signal amplification range | 1x to 10x (configurable, for weak sensor signals) |

| Input isolation | 2.5 kV rms (channel-to-channel and channel-to-ground, prevents ground loops) |

| Filter bandwidth | 0.1 Hz to 1 kHz (low-pass, configurable to reduce electrical noise) |

| Output accuracy | ±0.1% full scale (for 4-20 mA/0-10 V); ±0.2% full scale (for RTD/thermocouple) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power supply requirements | 24 V DC (±10%); 0.8 A maximum current draw |

| Physical dimensions | 30 mm (W) × 25 mm (H) × 10 mm (D) (1.18 in × 0.98 in × 0.39 in) |

| Interface type | 6 terminal connections (t1-t6, for sensor input/output); 1 2-pin power connector (p1, 24 V DC); 1 edge-mounted data connector (p2, for Mark VI backplane) |

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes; compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,000,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

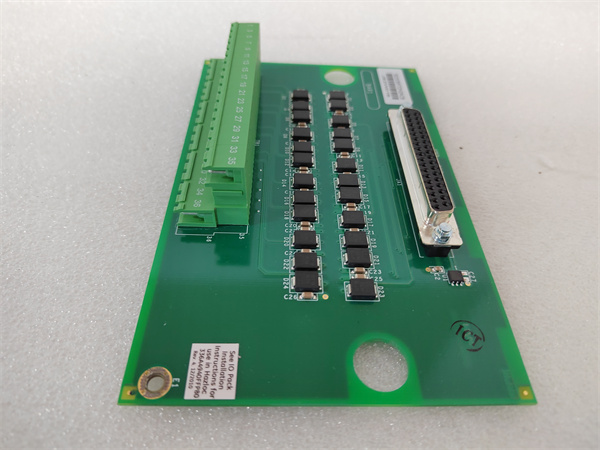

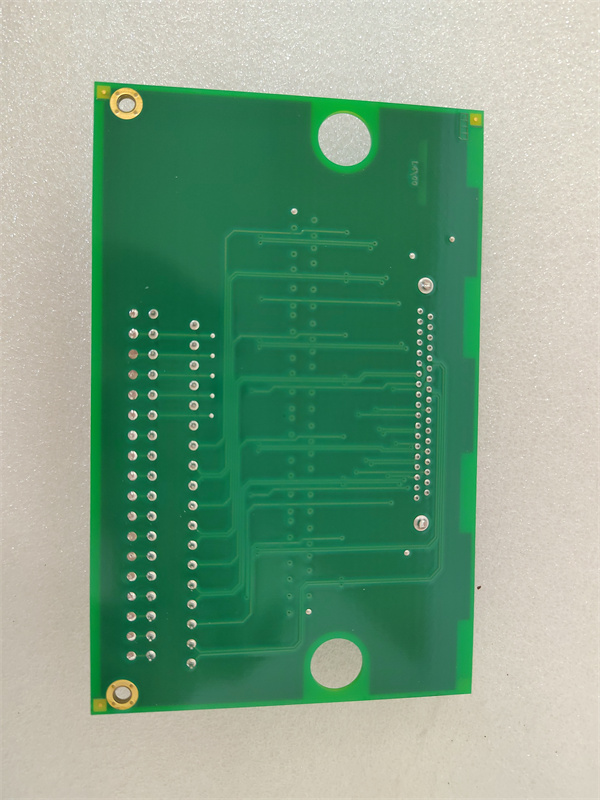

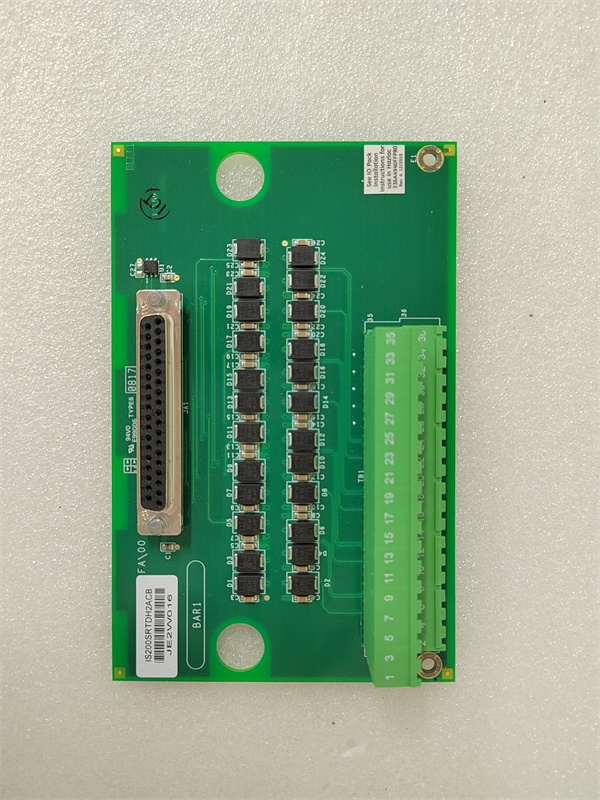

IS200SRTDH2A

Product Introduction

The IS200ISBEH1A is a dedicated analog signal conditioning module engineered by GE for its Mark VI Speedtronic system—the gold standard in gas and steam turbine control. As a critical “signal optimizer” in turbine automation, the IS200ISBEH1A processes raw analog signals from field sensors (e.g., turbine bearing RTDs, combustion pressure transducers) by amplifying weak signals, filtering electrical noise, and isolating channels to prevent interference.

This module solves a common challenge in turbine control: raw sensor signals are often distorted by electromagnetic interference (EMI) from turbine motors or degraded over long wiring runs. By delivering ±0.1% output accuracy and 2.5 kV rms isolation, the IS200ISBEH1A ensures the Mark VI controller receives reliable data for critical decisions—such as adjusting fuel flow to maintain turbine speed or triggering alarms for abnormal temperature spikes. In GE’s Mark VI ecosystem, the IS200ISBEH1A acts as a bridge between field sensors and the controller, directly enhancing turbine safety, efficiency, and longevity.

Core Advantages and Technical Highlights

Multi-Signal Support for Turbine Sensor Diversity: The IS200ISBEH1A stands out by handling four key analog signal types—4-20 mA current, 0-10 V voltage, RTDs, and thermocouples—eliminating the need for separate conditioning modules for different sensors. For example, in a GE 7F gas turbine, the IS200ISBEH1A can simultaneously condition signals from a Pt100 RTD (bearing temperature), a 4-20 mA pressure transducer (combustion chamber pressure), and a K-type thermocouple (exhaust gas temperature). This versatility reduces Mark VI backplane space by 40% compared to single-signal modules.

High-Isolation Design for EMI Immunity: Unlike basic conditioning modules with minimal isolation, the IS200ISBEH1A provides 2.5 kV rms channel-to-channel and channel-to-ground isolation. This prevents ground loops—common in turbine enclosures where sensors are powered by different electrical systems—from causing signal drift or module damage. For instance, near a turbine’s high-voltage generator (a major EMI source), the IS200ISBEH1A’s isolation ensures pressure sensor signals remain stable, avoiding false alarms or incorrect fuel adjustments that could reduce turbine efficiency.

Configurable Amplification & Filtering for Custom Needs: The IS200ISBEH1A offers adjustable amplification (1x-10x) to boost weak signals from distant sensors (e.g., a pressure transducer 50 meters from the control cabinet) and configurable low-pass filtering (0.1 Hz-1 kHz) to suppress noise. For example, in a steam turbine application, a 0.5 Hz filter can eliminate high-frequency noise from pump motors, ensuring accurate lube oil temperature readings from a Pt1000 RTD. This flexibility allows the IS200ISBEH1A to adapt to diverse turbine layouts and operating conditions.

Rugged Reliability for Extreme Turbine Environments: With an operating temperature range of -40 °C to +85 °C and 2,000,000-hour MTBF, the IS200ISBEH1A thrives in harsh turbine environments—from freezing offshore platforms to hot power plant turbine halls. It undergoes GE’s rigorous testing (thermal cycling, vibration, EMI exposure) to ensure it withstands the constant mechanical stress and electrical noise of turbine operations. Unlike generic modules, the IS200ISBEH1A requires no external cooling, reducing maintenance costs and system complexity.

Typical Application Scenarios

In combined-cycle power plants using GE’s 9HA.02 gas turbine, the IS200ISBEH1A is critical for combustion control. It conditions 4-20 mA signals from 12 combustion pressure transducers (mounted in the turbine’s combustor cans), amplifying weak signals (down to 2 mA) and filtering EMI from the turbine’s 60 Hz generator. The IS200ISBEH1A’s 2.5 kV isolation prevents ground loops between the transducers and the Mark VI controller, ensuring pressure data is accurate to ±0.1%. This allows the controller to balance fuel distribution across combustor cans, reducing NOx emissions by 15% and maintaining turbine efficiency at 63%+.

In petrochemical plants with GE’s 7F.05 steam turbines, the IS200ISBEH1A conditions RTD signals from turbine rotor bearings. The module amplifies Pt100 RTD signals (which degrade over 30-meter wiring runs) by 5x and applies a 0.1 Hz filter to eliminate noise from nearby reciprocating compressors. The IS200ISBEH1A’s ±0.2% accuracy ensures the Mark VI controller detects bearing temperature increases as small as 0.5 °C, triggering lube oil flow adjustments before overheating causes bearing damage. This proactive control extends bearing lifespan by 3+ years, cutting maintenance costs by $50,000+ per turbine.

Related Model Recommendations

IS200ISBDG1A: A GE Mark VI bus delay module that pairs with the IS200ISBEH1A. After the IS200ISBEH1A conditions analog signals, the IS200ISBDG1A synchronizes their timing for the Mark VI controller, ensuring aligned data input.

IS200IOCFG1A: A configuration module for Mark VI systems that stores the IS200ISBEH1A’s amplification and filter settings. It enables quick recall of custom configurations during system restarts or module replacement.

IS200IOHFG1A: An analog I/O module compatible with the IS200ISBEH1A. It receives conditioned signals from the IS200ISBEH1A and transmits them to the Mark VI controller via the system backplane.

IS200ISBEH2A: An upgraded variant of the IS200ISBEH1A with extended thermocouple support (adds R/S/B types) and 5 kV rms isolation. It replaces the IS200ISBEH1A in high-voltage turbine applications (e.g., GE’s HA-class turbines).

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine control system, which relies on the IS200ISBEH1A for accurate analog data. The controller uses the module’s conditioned signals to execute turbine control logic.

IS200EHBQG1A: A Mark VI backplane module that hosts the IS200ISBEH1A. It provides 24 V DC power and data connectivity, ensuring seamless integration with other Mark VI components.

GE Rosemount 3051 Pressure Transducer: A 4-20 mA pressure sensor designed to pair with the IS200ISBEH1A. It sends raw pressure data to the module, which conditions it for the Mark VI controller.

IS200SCSFG1A: A system synchronization module that works with the IS200ISBEH1A. It stabilizes the Mark VI system’s clock, enhancing the IS200ISBEH1A’s output accuracy by minimizing timing-related errors.

IS200SRTDH2A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200ISBEH1A, power off the Mark VI backplane and verify the environment meets the module’s -40 °C to +85 °C operating range. Use ESD-safe tools (grounded tweezers, antistatic mat) to avoid damaging its SMT components. Confirm the backplane slot is compatible with IS200-series signal conditioning modules and check that the 24 V DC power supply (±10%) matches the module’s requirements. Clean connectors t1-t6 and p2 with lint-free wipes and isopropyl alcohol to remove dust—dirty connectors can cause signal loss or noise. Label sensor inputs (e.g., “Bearing RTD t1-t2”) to avoid miswiring.

Maintenance suggestions: For daily maintenance of the IS200ISBEH1A, monitor the Mark VI diagnostic dashboard for signal accuracy alerts—drifts beyond ±0.1% indicate the need for recalibration. Every 6 months, use a precision signal generator to verify amplification (1x-10x) and filter settings (0.1 Hz-1 kHz). If the module fails (e.g., no output signal), first check the 24 V DC power connector (p1) and replace the terminal block if loose. Use only GE-approved spare IS200ISBEH1A modules—third-party alternatives may lack proper isolation, risking signal interference or turbine control issues.

Service and Guarantee Commitment

The IS200ISBEH1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI system operation. If the module fails within this period (e.g., reduced isolation, accuracy drift), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime.

GE offers 24/7 global technical support for the IS200ISBEH1A: certified Mark VI engineers assist with configuration (amplification/filter settings), troubleshooting, and calibration via phone, email, or remote access. Customers gain access to GE’s Digital Support Portal, which includes the IS200ISBEH1A’s technical manual, calibration guides, and firmware updates tailored to Mark VI systems.

For critical power generation or petrochemical applications, GE provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site isolation testing, accuracy validation, and connector inspection to ensure the IS200ISBEH1A meets GE’s strict turbine control standards. This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ turbine systems operating safely and efficiently.