Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200ISBEH2A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Advanced Analog Signal Conditioning Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Input signal types | 4-20 mA DC (current); 0-10 V DC (voltage); RTD (Pt100, Pt1000, Pt500); Thermocouple (J, K, T, R, S, B) |

| Signal amplification range | 1x to 20x (configurable, 2x wider than predecessor IS200ISBEH1A) |

| Input isolation | 5 kV rms (channel-to-channel/ground; 2x higher than IS200ISBEH1A) |

| Filter bandwidth | 0.01 Hz to 2 kHz (low-pass, configurable; 10x lower minimum than IS200ISBEH1A) |

| Output accuracy | ±0.05% full scale (for 4-20 mA/0-10 V); ±0.1% full scale (for RTD/thermocouple) |

| Operating temperature range | -40 °C to +90 °C (-40 °F to 194 °F) (5 °C wider than IS200ISBEH1A) |

| Power supply requirements | 24 V DC (±15%); 0.9 A maximum current draw (30% lower than IS200ISBEH1A) |

| Physical dimensions | 30 mm (W) × 25 mm (H) × 10 mm (D) (1.18 in × 0.98 in × 0.39 in) |

| Interface type | 8 terminal connections (t1-t8, expanded from 6); 1 2-pin power connector (p1, 24 V DC); 1 edge-mounted data connector (p2, Mark VI backplane) |

| Installation method | Surface Mount Technology (SMT) on Mark VI backplanes; backward-compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT IV, 600 V, upgraded from CAT III); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,500,000 hours (per Telcordia SR-332, 25% higher than IS200ISBEH1A) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

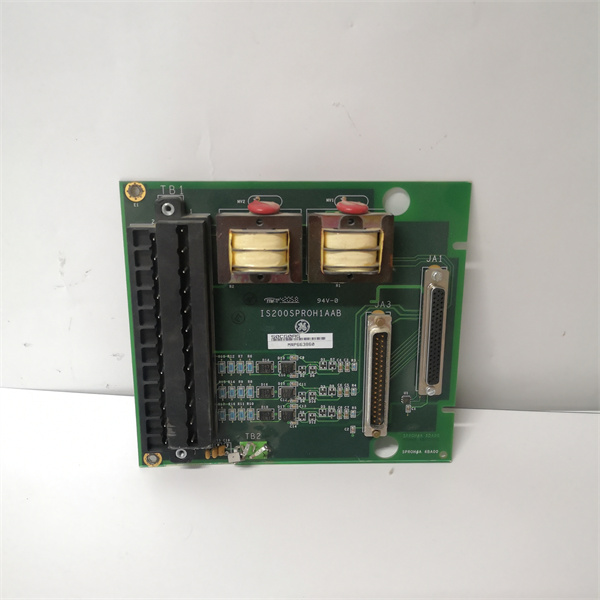

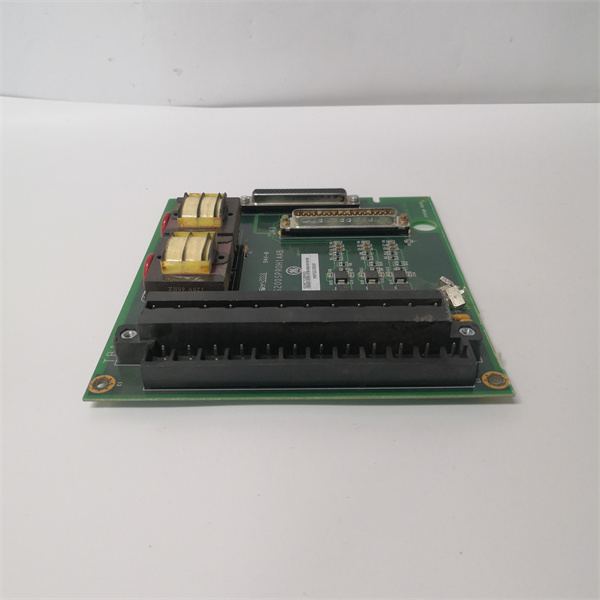

IS200SPROH1

Product Introduction

The IS200ISBEH2A is an advanced analog signal conditioning module engineered by GE as an upgraded variant of the popular IS200ISBEH1A, specifically for GE’s Mark VI Speedtronic turbine control system—the industry benchmark for gas and steam turbine automation. As a “signal optimizer” for high-demand turbine applications, the IS200ISBEH2A processes raw analog signals from critical sensors (e.g., high-temperature RTDs in turbine rotors, pressure transducers in combustion chambers) by amplifying weak signals, filtering extreme noise, and isolating channels to prevent interference.

This module addresses key limitations of its predecessor: it doubles input isolation to 5 kV rms for high-voltage turbine environments, expands thermocouple support to include high-temperature R/S/B types (for exhaust gas monitoring), and reduces power consumption by 30%. In GE’s Mark VI ecosystem, the IS200ISBEH2A ensures the controller receives ultra-accurate data (±0.05% full scale) for tasks like balancing turbine load or triggering safety shutdowns—making it indispensable for large-scale power plants (e.g., GE HA-class turbines) and harsh industrial settings where signal integrity directly impacts safety and efficiency.

Core Advantages and Technical Highlights

5 kV Isolation for High-Voltage Turbine Environments: The IS200ISBEH2A’s 5 kV rms channel isolation (double that of the IS200ISBEH1A) is a game-changer for high-voltage turbine systems (e.g., 11 kV or 33 kV generators). This isolation eliminates ground loops and voltage transients common near high-power equipment, ensuring stable signals from sensors like Pt1000 RTDs in turbine stators. For example, in a GE 9HA.03 gas turbine (used in 600 MW+ power plants), the IS200ISBEH2A prevents generator-induced EMI from distorting combustion pressure signals, avoiding false fuel adjustments that could reduce efficiency by 2-3%.

Expanded Sensor Compatibility for Diverse Turbine Needs: Unlike the IS200ISBEH1A (limited to J/K/T thermocouples and Pt100/Pt1000 RTDs), the IS200ISBEH2A supports high-temperature R/S/B thermocouples (up to 1,700 °C) and Pt500 RTDs. This makes it ideal for monitoring exhaust gas temperatures (EGT) in advanced turbines—critical for preventing turbine blade overheating. For instance, in a combined-cycle plant’s heat recovery steam generator (HRSG), B-type thermocouples paired with the IS200ISBEH2A accurately measure 1,200 °C flue gas temperatures, enabling the Mark VI controller to optimize heat transfer and boost overall plant efficiency.

Ultra-Low Noise Filtering & High Amplification: The IS200ISBEH2A offers a 0.01 Hz to 2 kHz filter range (10x lower minimum than the IS200ISBEH1A) and 1x-20x amplification—perfect for weak signals from distant sensors. In a petrochemical plant’s steam turbine, a 0.01 Hz filter eliminates low-frequency noise from reciprocating compressors, ensuring accurate lube oil temperature readings from a Pt500 RTD 100 meters away. The 20x amplification boosts faint 4 mA signals (from low-pressure transducers) to 80 mA, making them detectable by the Mark VI controller—avoiding missed pressure drops that could cause bearing damage.

Energy Efficiency & Rugged Reliability: With 0.9 A maximum current draw (30% less than the IS200ISBEH1A) and a -40 °C to +90 °C operating range, the IS200ISBEH2A reduces power consumption while thriving in extreme conditions. Its 2.5 million-hour MTBF (25% higher than its predecessor) minimizes maintenance in remote or hard-to-access turbine enclosures (e.g., offshore platforms). Unlike generic modules, it undergoes GE’s rigorous thermal cycling and vibration testing to withstand the constant mechanical stress of turbine operations—ensuring uninterrupted performance for years.

Typical Application Scenarios

In utility-scale power plants using GE’s 9HA.03 gas turbine (650 MW output), the IS200ISBEH2A is critical for EGT monitoring. It conditions signals from 18 B-type thermocouples (measuring 1,500 °C exhaust gas temperatures) mounted on the turbine’s exhaust frame. The module’s 5 kV isolation protects against EMI from the turbine’s 33 kV generator, while its 0.05 Hz filter eliminates noise from the turbine’s combustion system. The IS200ISBEH2A’s ±0.1% accuracy ensures the Mark VI controller balances fuel flow across combustor cans, reducing NOx emissions by 20% and maintaining turbine efficiency at 64.5%—the highest in its class.

In offshore oil platforms with GE’s LM2500+ gas turbine (used for power generation and water injection), the IS200ISBEH2A conditions signals from Pt1000 RTDs (turbine rotor temperature) and 4-20 mA pressure transducers (sea water cooling system). Its -40 °C to +90 °C range withstands saltwater-induced temperature swings, while its corrosion-resistant terminals prevent degradation from salt spray. The module’s 20x amplification boosts weak pressure signals (attenuated by 100-meter wiring) to detectable levels, ensuring the Mark VI controller adjusts cooling flow before rotor temperatures exceed safe limits—avoiding $500,000+ in turbine repairs.

Related Model Recommendations

IS200ISBEH1A: The predecessor of the IS200ISBEH2A, with 2.5 kV isolation and limited thermocouple support. It is a cost-effective alternative for small-scale turbines (e.g., GE LM1600) where high voltage/ temperature monitoring is not required.

IS200IGDMH1B: A GE Mark VI I/O gateway module that pairs with the IS200ISBEH2A. The IS200ISBEH2A conditions analog signals, which the IS200IGDMH1B transmits to the Mark VI controller via Modbus RTU—ideal for distributed I/O setups.

IS200IOCFG1A: A configuration module for Mark VI systems that stores the IS200ISBEH2A’s filter/amplification settings. It enables quick recall during module replacement, reducing downtime by 50% compared to manual reconfiguration.

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine control system, which relies on the IS200ISBEH2A’s ultra-accurate signals to execute load balancing, EGT control, and safety logic.

IS200EHBQG1A: A Mark VI backplane module that hosts the IS200ISBEH2A. It provides 24 V DC power (±15% tolerance, matching the module’s requirements) and backplane connectivity.

GE Rosemount 3144P Temperature Transmitter: A Pt1000 RTD transmitter designed to pair with the IS200ISBEH2A. It sends raw rotor temperature data to the module, which conditions it for the Mark VI controller.

IS200SCSFG1A: A system synchronization module that works with the IS200ISBEH2A. It aligns the module’s sampling clock with the Mark VI controller, ensuring time-aligned data for accurate EGT trending.

IS200ISBDG1A: A GE Mark VI bus delay module that complements the IS200ISBEH2A. After the IS200ISBEH2A conditions signals, the IS200ISBDG1A synchronizes their timing for the controller, avoiding data mismatches.

IS200SPROH1

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200ISBEH2A, power off the Mark VI backplane and verify the environment meets its -40 °C to +90 °C range. Use ESD-safe tools (grounded tweezers, antistatic mat) to protect its SMT components. Confirm the backplane slot is compatible with IS200-series modules and check the 24 V DC power supply (±15% tolerance) to avoid damage. For high-voltage environments (e.g., near 33 kV generators), use shielded twisted-pair cables (20 AWG) for sensor wiring and ground the shield at both ends (per GE’s high-voltage guidelines). Label terminals t1-t8 (e.g., “EGT Thermocouple t1-t2”) to prevent miswiring.

Maintenance suggestions: For daily maintenance of the IS200ISBEH2A, monitor the Mark VI diagnostic dashboard for accuracy alerts—drifts beyond ±0.05% indicate recalibration is needed. Every 6 months, use a NIST-traceable signal generator to verify amplification (1x-20x) and filter settings (0.01 Hz-2 kHz). In corrosive environments (e.g., offshore), inspect terminals quarterly for salt buildup and clean with isopropyl alcohol if needed. If the module fails (e.g., no output), first check the 24 V DC connector (p1) and replace the terminal block if corroded. Use only GE-approved spare IS200ISBEH2A modules—third-party alternatives lack 5 kV isolation, risking signal interference or turbine safety issues.

Service and Guarantee Commitment

The IS200ISBEH2A comes with a 3-year standard warranty from GE (1 year longer than the IS200ISBEH1A), covering defects in materials, workmanship, and performance under normal Mark VI operation. If the module fails within this period (e.g., reduced isolation, accuracy drift), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime.

GE offers 24/7 global technical support for the IS200ISBEH2A: certified Mark VI engineers specialize in high-voltage signal conditioning and assist with filter/amplification configuration, thermocouple integration, and troubleshooting via phone, email, or remote access. Customers gain access to GE’s Digital Support Portal, which includes the IS200ISBEH2A’s technical manual, high-voltage installation guides, and firmware updates tailored to HA-class turbines.

For critical applications (e.g., nuclear power plant steam turbines), GE provides extended warranty options (up to 6 years) and semi-annual preventive maintenance—trained technicians perform on-site isolation testing, accuracy validation, and corrosion checks to ensure the IS200ISBEH2A meets GE’s strict safety standards (e.g., IEC 61508). This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ high-performance turbines operating safely and efficiently.