Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

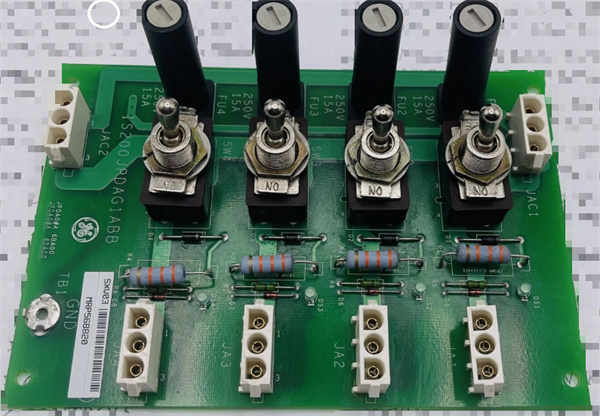

| Product model | IS200JPDAG1A |

| Manufacturer | General Electric (GE) |

| Product category | AC Power Distribution Board (Mark VI Speedtronic Turbine Control Series) |

| Power distribution capability | 4 independent switched AC output channels (single AC input to multiple loads) |

| Input power source | Powered by GE JPDB board via 5A fused branch circuit |

| Overcurrent protection | 15A main line fuse; individual fuses for each output channel (1/4″ to 1-1/4″ fuse compatibility) |

| Status indication | LED indicators for each output channel (power-on/ fault visualization) |

| Interface type | Compatible with GE Mark VI PPDA connector card (for JPDB board integration) |

| Operating temperature range | 0 °C to 60 °C (32 °F to 140 °F) |

| Storage temperature range | -40 °C to 85 °C (-40 °F to 185 °F) |

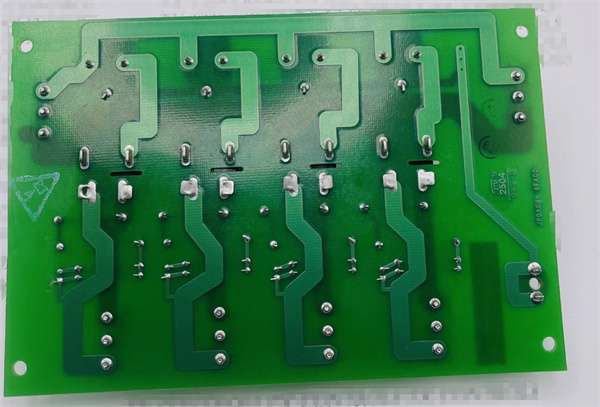

| Physical dimensions | 152.4 mm × 203.2 mm × 25.4 mm (6 in × 8 in × 1 in) [approximate, GE industrial standard] |

| Weight | 311.8 g (11 oz) |

| Coating | Standard industrial-grade conformal coating (for moisture/dust resistance) |

| Compliance standards | UL 508 (Industrial Control Equipment), IEC 61010-1 (Safety Requirements for Electrical Equipment), RoHS |

| Compatibility | GE Mark VI Speedtronic turbine control systems (gas/steam turbine applications) |

IS200JPDAG1A

Product Introduction

The IS200JPDAG1A is a high-reliability AC power distribution board manufactured by General Electric (GE), exclusively designed for integration into GE’s Mark VI Speedtronic turbine control system—the industry standard for gas and steam turbine management in power generation, oil & gas, and industrial manufacturing. As a core component of the Mark VI ecosystem, the IS200JPDAG1A solves a critical challenge: safely distributing a single AC power input to multiple I/O and control loads while providing robust overcurrent protection and real-time status monitoring.

Unlike generic power distribution boards, the IS200JPDAG1A is engineered to meet the 严苛 (demanding) requirements of turbine control environments. It interfaces seamlessly with GE’s JPDB board via a PPDA connector card, ensuring compatibility with existing Mark VI infrastructure. By centralizing power distribution and protection, the IS200JPDAG1A reduces wiring complexity, minimizes downtime from power-related faults, and ensures consistent power delivery to critical components like sensors, actuators, and communication modules—making it indispensable for maintaining turbine operational efficiency and safety.

Core Advantages and Technical Highlights

Modular Power Distribution with Individual Channel Protection: The IS200JPDAG1A’s 4 independent switched AC output channels enable targeted power delivery to specific turbine control components (e.g., pressure sensors, valve actuators). Each channel includes a dedicated fuse and switch, meaning a fault in one load (e.g., a short circuit in a sensor) only affects that channel—preventing system-wide power disruptions. For example, in a gas turbine plant, if a temperature sensor connected to Channel 2 of the IS200JPDAG1A fails, the channel’s fuse blows, isolating the fault while Channels 1, 3, and 4 continue powering other critical components. This modularity reduces unplanned downtime, a key advantage over non-channelized power boards.

Real-Time Status Monitoring via LED Indicators: The IS200JPDAG1A features LED indicators for each output channel, providing instant visual confirmation of power status (on/off) and fault conditions. Maintenance technicians can quickly identify a tripped fuse or disconnected load by checking the LEDs—eliminating the need for time-consuming multimeter testing. In a 24/7 power generation facility, this visibility cuts troubleshooting time from hours to minutes: if the LED for Channel 3 is off, technicians immediately know to inspect the channel’s fuse or connected load, ensuring fast restoration of service. This ease of diagnostics is a significant upgrade over legacy power boards without status feedback.

GE Mark VI Ecosystem Compatibility: The IS200JPDAG1A is purpose-built for GE’s Mark VI Speedtronic system, with a design that ensures plug-and-play integration with GE’s JPDB board (via PPDA connector) and other Mark VI components. This compatibility eliminates the risk of mismatched hardware, which can cause power instability or component damage. For example, a refinery upgrading its turbine control system can install the IS200JPDAG1A without modifying existing Mark VI wiring or software—reducing installation time and ensuring system-wide reliability. Generic power boards, by contrast, require custom adapters and often introduce compatibility issues that compromise turbine performance.

Industrial-Grade Durability: The IS200JPDAG1A includes a conformal coating and operates in a wide temperature range (0 °C to 60 °C), making it resistant to moisture, dust, and thermal stress—common in turbine enclosures. In a coastal power plant, where salt air can corrode unprotected electronics, the IS200JPDAG1A’s coating prevents rust and short circuits, extending its lifespan to 10+ years (vs. 3–5 years for uncoated boards). This durability reduces replacement costs and ensures consistent performance in harsh industrial environments.

Typical Application Scenarios

The IS200JPDAG1A is indispensable in GE Mark VI-based turbine control systems across industries. In power generation, it is used in combined-cycle gas turbine (CCGT) plants to distribute AC power to critical I/O components: the IS200JPDAG1A receives a single AC input from the JPDB board and powers four key loads—two pressure sensors (monitoring turbine inlet pressure), one valve actuator (controlling fuel flow), and one communication module (transmitting data to the plant’s SCADA system). Each load is protected by the IS200JPDAG1A’s dedicated fuses, ensuring a sensor fault doesn’t disrupt fuel flow control—a scenario that could lead to turbine shutdown. The LED indicators also let operators monitor power status from the control room, enhancing system visibility.

In oil & gas, the IS200JPDAG1A supports steam turbines used in pipeline compression stations. Here, the board powers corrosion-resistant sensors (monitoring pipeline pressure) and electric actuators (regulating flow valves). The IS200JPDAG1A’s industrial-grade design withstands the station’s high-vibration, dusty environment, while its modular protection ensures a failed actuator doesn’t cut power to the pressure sensors—critical for preventing pipeline overpressure events. By integrating with the Mark VI system, the IS200JPDAG1A also enables remote monitoring of power status, letting engineers in a central office track component health without on-site visits.

In industrial manufacturing, the IS200JPDAG1A is used in GE Mark VI-controlled steam turbines for process heating (e.g., in chemical plants). The board powers temperature sensors (monitoring process fluid temperature) and pump controllers (circulating fluid). Its compatibility with the Mark VI system ensures power distribution is synchronized with turbine speed and process demand—for example, increasing power to pump controllers when the turbine ramps up to meet higher heating requirements. This integration optimizes energy efficiency and ensures the process remains within safe temperature limits.

Related Model Recommendations

IS200JPDBH1A: GE’s JPDB board, the primary power source for the IS200JPDAG1A—supplies the 5A fused branch circuit that powers the distribution board. Required for IS200JPDAG1A operation in Mark VI systems.

IS200PPDAH1A: GE’s PPDA connector card, which enables physical and electrical connection between the IS200JPDAG1A and JPDB board. Ensures secure, compatible integration in Mark VI setups.

IS200JPDAG2A: An upgraded version of the IS200JPDAG1A with 6 output channels (vs. 4), designed for larger Mark VI systems with more I/O loads (e.g., multi-turbine plants).

IS200JPDCG1A: GE’s DC power distribution board, complementary to the IS200JPDAG1A—used in Mark VI systems needing DC power distribution (e.g., for low-voltage sensors) alongside AC distribution.

IS200TBAIH1A: GE’s terminal block assembly, paired with the IS200JPDAG1A to organize wiring for connected loads. Simplifies installation and maintenance by standardizing wire routing.

IS200JPDAG1B: A revision of the IS200JPDAG1A with enhanced fuse holders (compatible with larger 2″ fuses) for high-current loads (e.g., heavy-duty actuators) in industrial turbine systems.

IS200MDDHG1A: GE’s Mark VI I/O module, a common load powered by the IS200JPDAG1A—handles analog/digital signals from turbine sensors and sends commands to actuators.

IS200PCCAG1A: GE’s power conditioning card, used with the IS200JPDAG1A in unstable power environments (e.g., remote oil fields) to regulate input voltage and prevent voltage spikes from damaging the distribution board.

IS200JPDAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200JPDAG1A, confirm the host system is a GE Mark VI Speedtronic turbine control system with an available JPDB board and PPDA connector card. Power off the Mark VI system and disconnect all AC power sources to avoid electrical shock. Use an anti-static wristband when handling the IS200JPDAG1A to protect its components from electrostatic discharge. Gather tools: Phillips screwdriver (for mounting), torque wrench (to secure connectors to 0.5 N·m), and a multimeter (to verify input voltage post-installation). Align the IS200JPDAG1A with the Mark VI chassis mounting points, secure it with screws, then connect the PPDA connector card to the board and JPDB board. Ensure all fuses are installed (15A main fuse, appropriate fuses for each channel) before powering on.

Maintenance suggestions: Inspect the IS200JPDAG1A monthly: check LED indicators to confirm all channels are powered (no unexpected off states) and visually inspect fuses for signs of burning or corrosion. Every 6 months, use a soft brush to remove dust from the board’s conformal coating (avoiding water or harsh cleaners). If a channel’s LED is off, use a multimeter to test the fuse—replace with a GE-approved fuse of the same rating (do not use higher-amperage fuses, as this risks component damage). Annual maintenance should include verifying input voltage from the JPDB board (ensure it stays within 10% of nominal) and checking PPDA connector tightness. For persistent faults (e.g., repeated fuse tripping), contact GE service—do not modify the IS200JPDAG1A’s wiring or components, as this voids the warranty.

Service and Guarantee Commitment

The IS200JPDAG1A comes with a standard 2-year manufacturer’s warranty from GE, covering defects in materials and workmanship. GE guarantees the IS200JPDAG1A will operate in compliance with published specifications when integrated into GE Mark VI systems, with free repair or replacement of defective units. Customers can extend coverage to 5 years via GE’s Turbine Control Service Plan, which includes annual preventive maintenance, priority technical support, and expedited delivery of replacement parts (24–48 hour turnaround for critical components).

GE provides specialized support for the IS200JPDAG1A through its global network of turbine control experts: users gain access to technical manuals, video tutorials on installation/troubleshooting, and direct phone/email support for Mark VI system integration. For large-scale projects (e.g., power plant upgrades), GE offers on-site installation and commissioning services to ensure the IS200JPDAG1A is configured correctly and integrated seamlessly with existing Mark VI components. This commitment reflects GE’s confidence in the IS200JPDAG1A’s reliability and ensures customers maximize uptime for their turbine control systems.