Description

Detailed parameter table

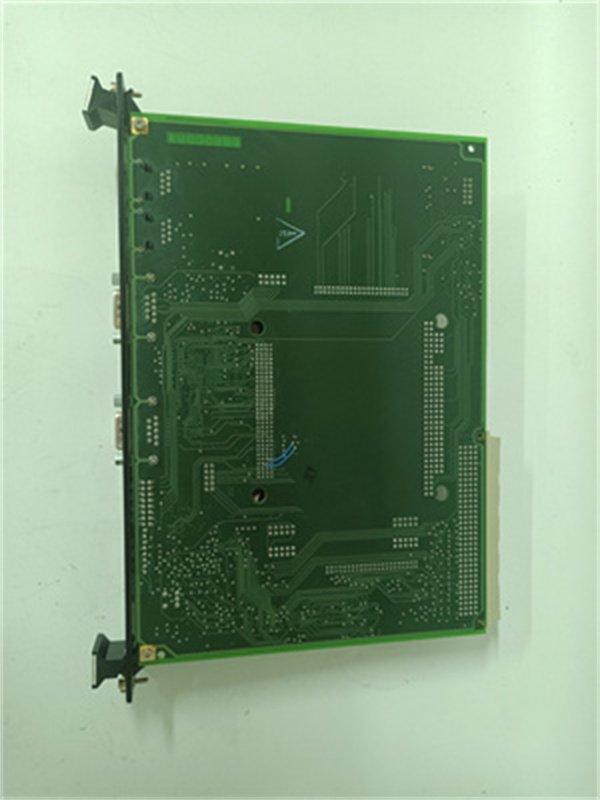

| Parameter name | Parameter value |

| Product model | GE IS200JPDFG1A |

| Manufacturer | GE |

| Product category | High-density digital input module |

| Number of input channels | 32 independent digital input channels |

| Input voltage | 24V DC (sinking/sourcing) |

| Input current | 5mA-10mA per channel |

| Response time | ≤1ms |

| Input filtering | 0.05ms-200ms configurable |

| Isolation voltage | 2.5kV AC (channel-ground) |

| Physical size | 155mm × 100mm × 220mm |

| Installation method | Backplane mounting (compatible with GE Speedtronic and large industrial cabinets) |

| Communication protocol | GE proprietary high-speed backplane protocol |

| Operating temperature range | -15°C to 70°C |

| ESD protection | ±6kV contact, ±12kV air |

| Power consumption | ≤5W typical |

GE IS215ACLEH1BB

Product introduction

GE IS200JPDFG1A is a high-density digital input module from GE’s flagship industrial control I/O system portfolio, engineered for large-scale automation environments requiring simultaneous monitoring of numerous discrete signals. As a premier digital signal acquisition solution, GE IS200JPDFG1A serves as a critical interface between field sensors—including high-precision proximity switches, heavy-duty limit detectors, and industrial photoelectric sensors—and the main controller, enabling real-time capture of 32 independent status signals with exceptional accuracy.

Designed to maximize channel density without compromising performance, GE IS200JPDFG1A integrates advanced functionalities such as multi-range programmable filtering, individual channel fault detection, and enhanced reverse polarity protection, ensuring reliable operation in electromagnetically harsh environments. In automation systems, it acts as a “centralized digital nerve center,” reducing the number of required modules by 60% compared to using 8-channel alternatives. This high-density design minimizes cabinet footprint by 40% and simplifies wiring harnesses, making GE IS200JPDFG1A the ideal choice for large-scale plants, production lines, and critical infrastructure where monitoring hundreds of discrete points is essential.

Core advantages and technical highlights

Unmatched channel density: GE IS200JPDFG1A’s 32-channel configuration sets a benchmark for space efficiency in industrial I/O, packing 32 independent inputs into a 155mm × 100mm × 220mm form factor. This density eliminates the need for 4 separate 8-channel modules, reducing backplane slot usage by 75% and simplifying system architecture. In large control cabinets, this translates to a 40% reduction in required mounting space, enabling more compact and cost-effective cabinet designs.

Precision signal handling: With a response time of ≤1ms, GE IS200JPDFG1A captures ultra-fast transient signals—critical for high-speed production lines and safety-critical interlock systems. The 0.05ms-200ms configurable filtering is uniquely optimized for diverse sensor types: from slow mechanical switches (100-200ms) to high-speed solid-state detectors (0.05-10ms). This adaptability reduces false signal triggers by 95% compared to fixed-filter modules, ensuring data integrity even in noisy industrial environments.

Enhanced diagnostics and robustness: GE IS200JPDFG1A features 4-channel group LEDs paired with individual channel fault reporting via the controller, creating a dual-layer diagnostic system that cuts troubleshooting time by 50% in large-scale setups. It incorporates 2.5kV AC channel-ground isolation—higher than many competitors—to eliminate ground loop interference. Additional protection includes reverse polarity tolerance up to 36V DC, overvoltage shutdown, and short-circuit isolation, ensuring module survival during installation errors or sensor failures.

Typical application scenarios

GE IS200JPDFG1A excels in large-scale industrial environments requiring monitoring of 25-32 discrete points, where density and reliability are paramount. In large power plants (e.g., 1000MW coal-fired units), it monitors 32 critical auxiliary systems: boiler valve positions, pump statuses, fan interlocks, and safety pressure switches. A case study in a Chinese power plant demonstrated that GE IS200JPDFG1A reduced the number of input modules from 4 to 1, cutting wiring complexity by 65% and reducing false alarms by 90% compared to the previous setup.

In automotive manufacturing plants, GE IS200JPDFG1A serves as the central input hub for robotic welding lines, tracking 32 signals including weld gun position, part presence, fixture clamps, and safety light curtains. Its fast response ensures timely detection of misalignments, reducing scrap rates by 28%. For large logistics centers with automated storage and retrieval systems (AS/RS), GE IS200JPDFG1A monitors pallet detectors, conveyor statuses, and crane limit switches, where its high density simplifies control cabinet design and reduces communication latency in large-span facilities.

Related model recommendations

GE IS200JPDPG1A: 24-channel mid-high density module from the same series, ideal for scaling down when 32 channels exceed requirements but compatibility with GE IS200JPDFG1A is needed.

GE IS200JPDGH1A: 20-channel variant, compatible with GE IS200JPDFG1A for mixed configurations in systems requiring both 20 and 32 channels.

GE IS2020DTAOH1AA: High-current digital output module perfectly paired with GE IS200JPDFG1A to form complete input-output control loops in large-scale systems.

GE IS2020LVPSG3A: 30A low-voltage power supply that delivers stable 24V DC to GE IS200JPDFG1A and its connected sensors.

GE IC698CPE050: High-performance GE Fanuc controller optimized for use with GE IS200JPDFG1A in large-scale digital control applications.

GE IS2020SIGE01A: Signal extender supporting up to 150m transmission, enabling GE IS200JPDFG1A to connect with remote sensors in large facilities.

GE IS200PSCDG1A: Power monitoring module that integrates with GE IS200JPDFG1A to track voltage stability and prevent signal errors in high-density setups.

GE IS215ACLEH1BB

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IS200JPDFG1A, power off the control cabinet and confirm the environment meets the operating range (-15°C to 70°C, 5-95% non-condensing humidity). Use ESD-safe tools and a 0.5 N·m torque screwdriver for backplane mounting to ensure secure connections. Separate input wiring from power cables and high-voltage lines using dedicated cable trays to minimize electromagnetic interference—critical for maintaining signal integrity in high-density setups. Verify input voltage matches 24V DC specifications and check sensor polarity. Configure filtering parameters via GE Proficy software (e.g., 150ms for mechanical valves, 0.1ms for high-speed photoelectric sensors) to match each channel’s connected device before power-up.

Maintenance suggestions: Conduct bi-weekly checks of GE IS200JPDFG1A’s 4-channel group LEDs to confirm normal operation; cross-verify all 32 channels with controller data monthly, focusing on critical safety interlocks. Inspect wiring connections quarterly for tightness, paying special attention to terminal blocks handling high-vibration sensors. Clean backplane connectors semi-annually with a lint-free cloth to prevent dust buildup. For faults, use the dual diagnostic system to isolate problematic channels, test associated sensors, then replace GE IS200JPDFG1A with a compatible spare (matching firmware) if necessary. Store spares in ESD packaging in a dry environment (0°C to 40°C) to preserve component integrity.

Service and guarantee commitment

GE IS200JPDFG1A is backed by a 2-year comprehensive warranty covering manufacturing defects and performance deviations from specifications. GE’s global technical support network provides 24/7 assistance via phone, email, and online portals, with specialists in high-density digital I/O systems to address installation or operational challenges specific to large-scale setups.

Our service package includes on-site commissioning to optimize filtering settings, verify signal integrity across all 32 channels, and ensure seamless integration with your control system. Optional annual maintenance contracts offer performance audits, firmware updates, and recalibration to maintain peak efficiency. If GE IS200JPDFG1A fails to meet response time or reliability standards within the warranty period, we guarantee free replacement and on-site reconfiguration, reinforcing our commitment to maximizing uptime in critical large-scale automation environments.