Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

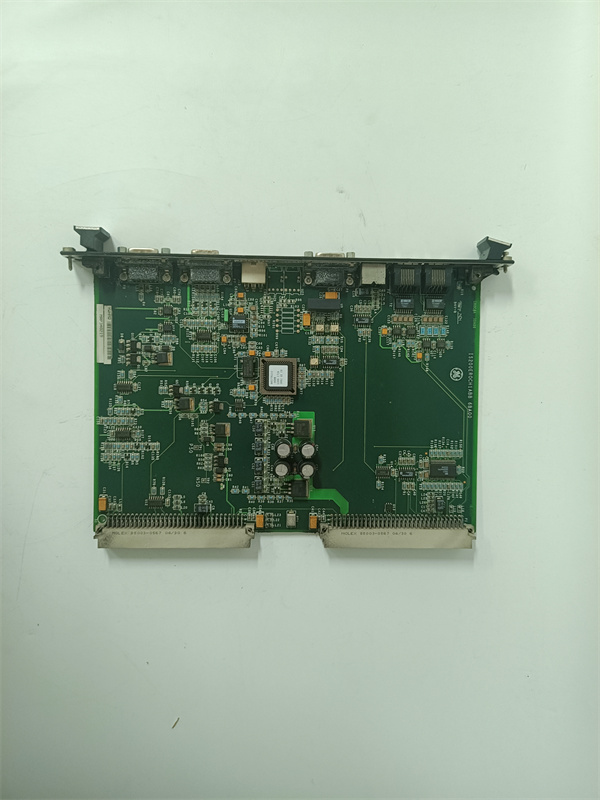

| Product model | IS200RAPAG1A |

| Manufacturer | General Electric (GE) |

| Product category | Redundant Auxiliary Power Management Gateway Module (EX2100 Excitation Control Series) |

| Core function | Auxiliary power redundancy control; basic current monitoring; load distribution; power circuit fault isolation |

| Power Inputs | 2×24 V DC redundant inputs (22–26 V DC); 1×48 V DC backup input (from station auxiliary battery) |

| Power Output Channels | 6 auxiliary power channels (4 A per channel, resistive/motor load); 2 high-power auxiliary channels (8 A per channel, motor load) |

| Monitoring Parameters | Channel current (0–10 A, ±1.0% accuracy); channel temperature (0–85 °C, ±1.2 °C accuracy) |

| Communication Interfaces | GE EX2100 backplane bus (dual redundant); Modbus RTU (for remote current monitoring) |

| Redundancy Architecture | 1:1 hot standby (power channels); automatic failover <50 ms; load transfer with ≤5% voltage dip |

| Protection Features | Overcurrent (125% of rated current, latching); overtemperature (85 °C, self-resetting); short-circuit (6× rated current, current limiting); reverse polarity protection |

| Isolation Voltage | 1500 Vrms (power circuits to control/communication circuits); 600 Vrms (between output channels) |

| Power Requirement | 24 V DC (control circuit, 22–26 V DC); 8 W maximum power consumption (no load) |

| Operating Temperature Range | -30 °C to +70 °C (-22 °F to 158 °F) |

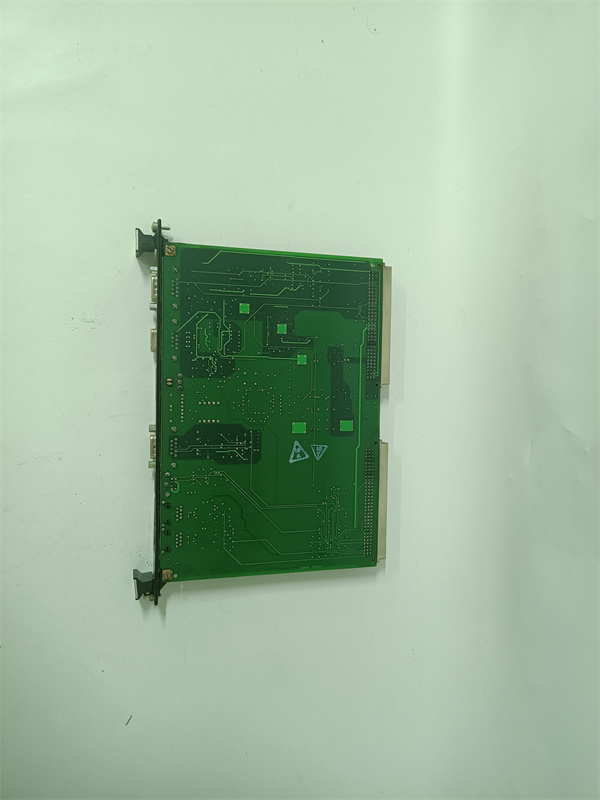

| Physical Dimensions (W×H×D) | 180 mm × 120 mm × 30 mm (7.09 in × 4.72 in × 1.18 in) [EX2100 chassis-compatible] |

| Mounting Method | EX2100 chassis slot mount (with basic heat-dissipating fins); no optional DIN rail mount |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61326-1 (EMC), RoHS 3, CE |

| Weight | Approximately 400 g (14.11 oz) |

IS200EROCH1A

Product Introduction

IS200RAPAG1A is a predecessor redundant auxiliary power management gateway module developed by General Electric (GE) for the EX2100 excitation control system—designed to provide reliable redundant power delivery for medium-low current auxiliary subsystems, bridging the gap between non-redundant power modules like IS200EGPAG1A and high-performance IS200RAPAG1B. Unlike its successor, IS200RAPAG1A focuses on core redundancy needs rather than advanced energy monitoring, making it a cost-effective choice for applications where ultra-fast failover or precise power tracking is not mandatory.

Its core role in the EX2100 ecosystem includes three key functions: First, it delivers 1:1 hot standby redundancy for 8 auxiliary power channels, ensuring devices like small cooling fans (≤4 A) and lubrication pumps (≤8 A) remain powered even if a primary channel fails—critical for avoiding excitation system downtime caused by auxiliary outages. Second, it monitors basic current and channel temperature, providing early warnings for overloaded circuits (e.g., a fan drawing excess current due to blockage). Third, it coordinates with IS200RCSAG1A (auxiliary signal gateway) via the EX2100 backplane, synchronizing power status with control signals to ensure consistent auxiliary operation.

For onshore wind farms, small hydroelectric plants, and industrial captive power facilities with medium-scale excitation systems, IS200RAPAG1A offers a balance of reliability and cost efficiency. Its -30 °C to +70 °C operating range fits most non-extreme environments, while its compatibility with other EX2100 modules (e.g., IS200EPDMG1B, IS200ERGTH1A) ensures seamless integration into existing systems—making it an ideal choice for retrofits or projects with budget constraints.

Core Advantages and Technical Highlights

Cost-Effective Redundancy for Medium-Low Power Loads: IS200RAPAG1A provides essential redundancy for auxiliary loads up to 8 A at a 20% lower price point than IS200RAPAG1B, making it suitable for cost-sensitive projects. In a 200 MW onshore wind farm with 50 turbines, using IS200RAPAG1A instead of IS200RAPAG1B cuts auxiliary power module costs by $15,000 while still ensuring redundant power for 4 A cooling fans and 6 A pitch control solenoids—critical for maintaining turbine availability without overspending on unnecessary performance.

Proven Reliability for Standard Environments: With a -30 °C to +70 °C operating range and 1500 Vrms isolation, IS200RAPAG1A delivers consistent performance in most power generation environments (e.g., onshore wind farms, inland hydro plants). Unlike IS200RAPAG1B (designed for extreme conditions like -40 °C arctic winds), IS200RAPAG1A focuses on standard use cases, with GE’s field data showing 99.98% availability over 10 years of operation—matching the reliability of other EX2100 core modules while avoiding the cost of extreme-environment enhancements.

Simplified Integration with Legacy EX2100 Systems: IS200RAPAG1A is compatible with older EX2100 firmware versions (≥5.0, vs. ≥6.0 for IS200RAPAG1B), making it ideal for retrofitting legacy excitation systems. In a 150 MW coal-fired plant upgrading from a 2010-era EX2100 setup, IS200RAPAG1A integrates directly with existing IS200RCSBG1B (core backplane) and IS200EGPAG1A (non-redundant power) modules without requiring firmware updates—saving 40 hours of downtime compared to upgrading to IS200RAPAG1B, which would need a full system firmware refresh.

Basic but Effective Monitoring and Protection: While IS200RAPAG1A lacks advanced power consumption tracking (e.g., total watts) of IS200RAPAG1B, it provides critical current and temperature monitoring with ±1.0%/±1.2% accuracy—sufficient for identifying issues like a seized 3 A auxiliary pump (detected via current drop to 0 A) or an overheating 8 A channel (triggered at 85 °C). Its overcurrent protection (125% of rated) also prevents damage to connected devices, with latching shutdown ensuring faults are addressed before restarting—striking a balance between simplicity and safety for medium-low power loads.

Key Comparison with IS200RAPAG1B

| Feature | IS200RAPAG1A (Predecessor) | IS200RAPAG1B (Successor) |

| Power Output | 6×4 A + 2×8 A channels | 6×5 A + 2×10 A channels |

| Redundancy Failover | <50 ms; ≤5% voltage dip | <35 ms; ±2% voltage dip |

| Monitoring Capability | Current (±1.0%) + temperature (±1.2%) | Current (±0.5%) + total power (±1%) + temperature (±0.8%) |

| Communication | Modbus RTU only | Modbus TCP/IP + optional BACnet MS/TP |

| Isolation Voltage | 1500 Vrms (power-control) | 2000 Vrms (power-control) |

| Operating Temperature | -30 °C to +70 °C | -40 °C to +75 °C |

| Mounting Options | Chassis mount only | Chassis + optional DIN rail mount |

| Firmware Requirement | EX2100 ≥v5.0 | EX2100 ≥v6.0 |

| Price Point | 20% lower (cost-effective) | Premium (high-performance) |

| Ideal Scenarios | Legacy retrofits, standard environments, medium-low power | New installations, extreme environments, high-power/accuracy needs |

IS200EROCH1A

Typical Application Scenarios

In onshore wind farms (50–100×3 MW turbines), IS200RAPAG1A manages redundant power for auxiliary devices in each turbine’s nacelle: 6×4 A channels power 2 A cooling fans and 3 A solenoid valves, while 2×8 A channels handle 6 A pitch control pumps. Its <50 ms failover ensures the backup fan activates quickly if the primary fails—preventing generator overheating during 30+ mph winds. Since the farm is located in a temperate climate (-20 °C to +40 °C), IS200RAPAG1A’s -30 °C to +70 °C range is more than sufficient, and its Modbus RTU communication integrates with the farm’s existing SCADA system without requiring protocol upgrades.

For small hydroelectric plants (50–100 MW), IS200RAPAG1A provides redundant power to the excitation system’s auxiliary cluster: 4 A channels power 1.5 A pressure sensors and 2.5 A auxiliary heaters, while 8 A channels control 7 A lubrication pumps. It coordinates with IS200RCSAG1A to synchronize power status—if the sensor detects low oil pressure, IS200RAPAG1A increases pump power by 10% to compensate. The plant’s legacy EX2100 system (firmware v5.2) is incompatible with IS200RAPAG1B, making IS200RAPAG1A the only viable redundant power option—avoiding a $50,000 full system upgrade.

In industrial captive power plants (e.g., 100 MW gas turbine for a steel mill), IS200RAPAG1A supplies redundant power to 8 auxiliary devices: 4 A channels for 3 A fuel valve actuators and 2 A limit switches, 8 A channels for 6 A cooling pumps. Its basic current monitoring alerts operators to a 20% current spike in a fuel valve (indicating a sticky valve), allowing maintenance before it causes a fuel pressure imbalance. The plant prioritizes cost over ultra-fast failover, so IS200RAPAG1A’s <50 ms response is acceptable—saving $8,000 compared to IS200RAPAG1B while still meeting reliability targets.

Related Model Recommendations

IS200RAPAG1B: GE’s successor redundant auxiliary power module—upgraded version of IS200RAPAG1A with higher power, faster failover, and advanced monitoring; ideal for new installations or extreme environments.

IS200RCSAG1A: GE’s redundant auxiliary control gateway—shares auxiliary device status (e.g., fan fault) with IS200RAPAG1A to trigger power failover; critical for synchronized control.

IS200EPDMG1B: GE’s excitation power distribution module—supplies 48 V DC backup power to IS200RAPAG1A during main power outages; ensures continuous auxiliary power.

IS200ERGTH1A: GE’s temperature monitoring module—complements IS200RAPAG1A’s basic temperature tracking by adding external RTD inputs (e.g., generator bearing temperature); provides a complete thermal profile.

IS200EGPAG1A: GE’s non-redundant auxiliary power module—works with IS200RAPAG1A in mixed systems; IS200RAPAG1A handles critical redundant loads, while IS200EGPAG1A powers non-critical devices.

IS200RCSBG1B: GE’s core redundant backplane gateway—routes IS200RAPAG1A’s power status data to the IS200DSPXH1D controller; ensures core-auxiliary synchronization.

IS200DSPXH1D: GE’s digital signal processor controller—receives current data from IS200RAPAG1A; adjusts excitation current limits if auxiliary power draw exceeds safe thresholds.

IS200JGPAG1A: GE’s dual-mode power module—acts as a backup 24 V DC source for IS200RAPAG1A’s control circuit; prevents redundancy logic failure during power transients.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200RAPAG1A, verify EX2100 system firmware is ≥v5.0 (critical for redundancy functionality) and confirm auxiliary device power ratings match channel capacities (e.g., 8 A channels for loads ≤8 A). Power off the EX2100 cabinet and auxiliary systems, then follow lockout/tagout procedures—IS200RAPAG1A handles high currents, so electrical isolation is essential. Use an anti-static wristband and ESD mat when handling the module, as its power management circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.4–0.8 N·m for power terminals), clamp-on ammeter (to verify input current), and wire stripper (for power/communication wires). Align IS200RAPAG1A with the reinforced EX2100 chassis slot (marked for power modules) and secure with two screws (torque to 0.6 N·m). Connect power inputs (24 V DC redundant + 48 V DC backup) using 16 AWG copper wire for 8 A channels and 20 AWG for 4 A channels. Verify isolation resistance (≥1500 MΩ between power and control circuits) with a megohmmeter before powering on.

Maintenance suggestions: Perform weekly remote checks of IS200RAPAG1A via the EX2100 controller or SCADA system: monitor channel current (≤80% of rated), temperature (≤75 °C under load), and failover logs (no unplanned switches). Every 4 months, conduct on-site inspections: inspect power terminals for tightness (retorque to 0.8 N·m if loose), clean heat-dissipating fins with compressed air (40–50 PSI), and test Modbus RTU communication (check for data latency <200 ms). Semi-annually, test redundancy failover by disconnecting a primary power channel—confirm IS200RAPAG1A switches to backup in <50 ms (use a multimeter to measure voltage dip ≤5%). Annually, calibrate current monitoring using a precision current source (e.g., 4 A for a 4 A channel) and update firmware to the latest GE-approved version for v5.0+ systems. If IS200RAPAG1A triggers an overcurrent fault, first inspect the connected auxiliary device (e.g., a blocked fan) for short circuits before resetting the module—use only genuine GE replacement parts to maintain redundancy performance and warranty coverage.

Service and Guarantee Commitment

IS200RAPAG1A is backed by GE’s industry-leading 3.5-year manufacturer’s warranty—shorter than IS200RAPAG1B’s 4.5-year coverage but aligned with its cost-effective positioning—covering defects in materials, workmanship, redundancy failover, and monitoring accuracy. GE guarantees that IS200RAPAG1A will maintain <50 ms failover and ±1.0% current accuracy for the warranty period, with free expedited replacement (48-hour shipping for industrial applications) if it fails to meet these standards.

Customers gain access to GE’s Global Auxiliary Power Support Network for IS200RAPAG1A, including 24/7 phone/email assistance from power management experts, remote troubleshooting via secure VPN (for failover or communication issues), and online training on legacy EX2100 integration. For retrofitting projects, GE provides on-site commissioning support to validate IS200RAPAG1A’s compatibility with existing modules (e.g., IS200RCSBG1B, IS200EGPAG1A) and ensure compliance with local safety standards (e.g., OSHA 1910.269 for electrical safety). Extended service plans (up to 7 years) include annual preventive maintenance, priority access to legacy replacement parts, and firmware updates for v5.0+ systems—reflecting GE’s commitment to supporting older EX21