Description

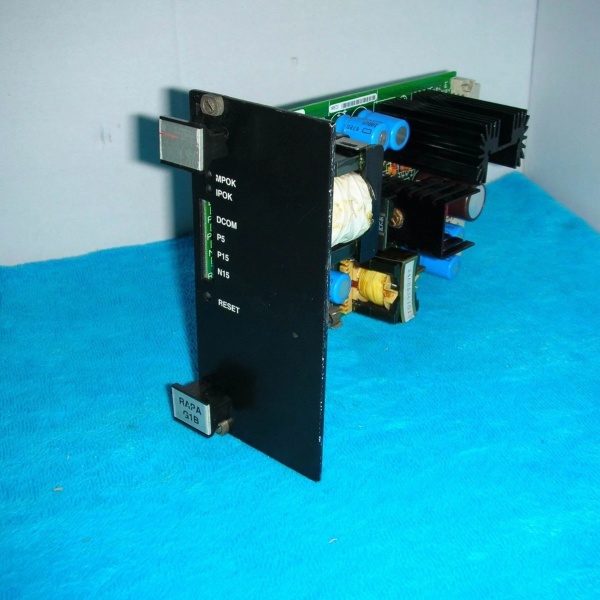

GE IS200RAPAG1BBA Mark VIe Redundant Power Adapter Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS200RAPAG1BBA** Manufacturer | GE General Electric Product Category | Industrial Redundant Power Adapter Module Series | Mark VIe (Turbine Control System) Redundancy Mode | 1+1 Hot Standby, Automatic Switchover (≤10ms) Input Voltage | 100-240V AC (Dual Independent Input) Output Voltage | 24V DC ±0.8V (Dual Isolated Output) Output Current | 15A per Channel, 30A Total (Dual Channel Parallel) Efficiency | ≥88% (Full Load) Ripple and Noise | ≤100mVpp Isolation Voltage | 2000V AC (Input to Output, Channel to Channel) Protection Functions | Overvoltage, Overcurrent, Short Circuit, Over Temperature Diagnostic Signals | Power Status (OK/FAULT), Redundancy Switchover Status Operating Temperature | -10°C to 65°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 150mm × 120mm × 35mm Certifications | UL 508, CE, CSA, IEC 61010-1 Communication Interface | GE SRTP (for Status Feedback), MODBUS RTU (Optional)

Product Introduction

The **GE IS200RAPAG1BBA** is a cost-effective and reliable redundant power adapter module customized for GE’s Mark VIe turbine control system, focusing on providing continuous and stable redundant DC power supply for conventional critical components of turbine control systems. As a core power guarantee unit in GE’s industrial basic redundant portfolio, this module is mainly used to supply power to key devices such as turbine standard control modules (e.g., IS200MACCH1A), general I/O modules (e.g., IS200AEACH1A), and basic safety interlock systems. By adopting a mature 1+1 hot standby redundant architecture, it effectively avoids control system downtime caused by single power channel failures, ensuring the continuous operation of turbine control links. Its reliable switchover performance, stable power output, and high compatibility make it a preferred power supply equipment for onshore thermal power plant auxiliary turbines, industrial boiler steam turbines, and medium-sized hydropower units—scenarios that require basic redundant power support without ultra-high performance indicators.

What distinguishes the **GE IS200RAPAG1BBA** is its balanced performance, high cost-effectiveness, and wide compatibility—advantages that meet the core demand for basic redundant power supply in conventional turbine control scenarios. Leveraging GE’s mature redundant power management technology, the module adopts dual independent power channels with isolated hardware design, each integrating a reliable switching power supply, voltage regulation circuit, and status monitoring unit. The automatic switchover time between channels is less than 10ms, which is shorter than the power-off retention time of mainstream Mark VIe control modules, ensuring no impact on the normal operation of the control system during switching. With ≥88% full-load efficiency, it balances energy consumption and cost, while 2000V AC isolation and essential protection functions (overvoltage, overcurrent, etc.) effectively resist common power grid fluctuations and industrial interference. By providing a solid basic “power safety net” for the turbine control system, it supports the stable operation of conventional turbine units at a reasonable cost.

IS200RAPAG1BBA

Core Advantages and Technical Highlights

1+1 Hot Standby Redundancy and Reliable Switchover: The **IS200RAPAG1BBA** adopts a practical 1+1 hot standby redundant design. Under normal conditions, two power channels operate simultaneously and share the load current equally (each channel bears 50% of the load). The built-in redundant control unit continuously monitors the core operating status of both channels (including input voltage, output voltage, and module temperature). When a fault (such as input power failure, output overvoltage, or module overheating) occurs in one channel, the system automatically switches the entire load to the normal channel within 10ms, with the output voltage fluctuation controlled within ±0.5V during the switching process. The switchover status is immediately fed back to the upper control system via GE SRTP protocol, facilitating maintenance personnel to quickly locate and handle faults.

Stable Power Conversion and Wide Adaptability: Each power channel of the module adopts a mature switching power supply design with ≥88% full-load efficiency, which meets the energy consumption requirements of conventional industrial control scenarios and avoids excessive heat generation in the control cabinet. The output voltage is stabilized at 24V DC ±0.8V, and the ripple and noise are controlled within 100mVpp, ensuring that the electronic components of the Mark VIe standard control module (such as microprocessors and signal conversion chips) receive stable power. The module supports a wide input voltage range of 100-240V AC, which can adapt to different power grid standards in most onshore industrial scenarios, eliminating the need for additional voltage conversion equipment and improving on-site application convenience.

Essential Protection and Practical Diagnostic Functions: The module is equipped with a practical multi-level safety protection system, including output over-voltage protection (DC ≥29V), over-current protection (per channel ≥18A), short-circuit protection (automatic current limiting and recovery), and over-temperature protection (≥90°C). When an abnormal condition occurs, the module quickly cuts off the faulty channel output and triggers an alarm, while ensuring the normal operation of the standby channel to avoid power supply interruption. The built-in diagnostic unit focuses on core status monitoring, outputting power OK/fault and redundancy switchover status signals to the upper system, which meets the basic fault identification needs of conventional turbine control systems and simplifies on-site maintenance.

High Compatibility with Mark VIe Ecosystem: The **IS200RAPAG1BBA** is designed with a standard Mark VIe chassis mounting interface, which can be directly installed in the Mark VIe control cabinet and perfectly matched with the basic redundant architecture of the conventional control system. It supports dual independent input power supplies (connected to the plant’s main power grid and standby power grid) to avoid common-point faults in the input link. The module communicates with the Mark VIe standard control module (IS200MACCH1A) through GE SRTP protocol, realizing real-time synchronization of core power status data. It can be optionally configured with MODBUS RTU protocol to connect to third-party conventional monitoring systems. The module supports online firmware update without power-off, ensuring the maintainability of the basic redundant power system.

Typical Application Scenarios

In onshore thermal power plant auxiliary steam turbine systems (such as feedwater pump and induced draft fan turbines), the **IS200RAPAG1BBA** serves as the core redundant power supply unit for the Mark VIe system. It provides continuous 24V DC power for key components such as the auxiliary turbine control module (IS200MACCH1A), general I/O module (IS200AEACH1A), and basic emergency shutdown system. The module’s two input channels are respectively connected to the plant’s main power grid and diesel generator backup power grid. When the main power grid fails due to line maintenance, the module completes the switch to the diesel generator power supply channel within 8ms, and the auxiliary turbine control system does not experience power interruption, ensuring the normal operation of the main turbine’s auxiliary systems and avoiding the impact on the power plant’s power generation efficiency.

In industrial boiler supporting steam turbine systems (such as chemical, textile, and paper mill self-provided power turbines), the **IS200RAPAG1BBA** is responsible for supplying power to the turbine control system and on-site monitoring equipment. Its -10°C to 65°C operating temperature range adapts to the temperature changes of industrial workshop control rooms, and the stable 24V DC output ensures the reliable operation of the turbine’s fuel control, speed regulation, and load adjustment systems. When the workshop’s main power supply is unstable (such as voltage fluctuation or short-term interruption), the module’s redundant switchover function ensures that the turbine control system continues to operate normally, avoiding production interruptions caused by turbine shutdown and reducing economic losses for enterprises.

In medium-sized hydropower plant turbine systems (onshore, stable operating environment), the **IS200RAPAG1BBA** provides redundant power supply for the turbine control system and safety monitoring components, including the governor control module, bearing temperature monitoring system, and gate opening control module. Its 2000V AC isolation performance effectively resists interference from the hydropower plant’s power generation equipment, and the essential over-current and over-temperature protection functions prevent fire hazards caused by power module failures. The module’s reliable redundant power supply ensures that the hydropower turbine can continue to operate stably even when the local power grid is interrupted, improving the power supply reliability of the hydropower plant for the surrounding area.

Related Model Recommendations

**IS200RAPAG2BBA**: High-power variant of **IS200RAPAG1BBA**, with 25A per channel output current and 50A total load capacity, suitable for large-scale conventional Mark VIe systems (such as multi-auxiliary turbine power plants).

**IS200MACCH1A**: Standard Mark VIe control module that receives power status data from **IS200RAPAG1BBA** through GE SRTP protocol, and triggers basic fault handling logic when the power supply is abnormal.

**IS200PWRPG1A**: Mark VIe power distribution module that distributes the stable 24V DC output of **IS200RAPAG1BBA** to multiple sub-modules, with independent fuses and status indicators for each output branch, improving power supply management convenience.

**IS200AEACH1A**: General analog input module that relies on the stable power supply of **IS200RAPAG1BBA** to realize reliable acquisition of turbine basic analog signals, ensuring the integrity of the control system’s signal acquisition link.

**IC754VSF08CTD**: Standard GE VersaMax HMI that displays the real-time power status and switchover information of **IS200RAPAG1BBA**, facilitating on-site operators to monitor and manage the power system.

**IS200MCCPG1A**: Basic Mark VIe communication module that transmits the core status data of **IS200RAPAG1BBA** to the plant-level conventional SCADA system, realizing centralized monitoring of the power supply status.

**IS200BATP1A**: Mark VIe backup battery module matched with **IS200RAPAG1BBA**, providing short-term emergency power supply (≥8 minutes) when both dual input power supplies fail, ensuring the safe shutdown of the conventional turbine control system.

IS200RAPAG1BBA

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS200RAPAG1BBA**, power off the entire Mark VIe control cabinet and confirm the compatibility of the mounting slot (reserve sufficient heat dissipation space around the module, ≥8cm). The dual input power supplies of the module must be connected to two independent power sources (such as main power grid and standby generator) to avoid common-point faults; use copper core cables with cross-sectional area ≥2.5mm² for input wiring, and ≥1.5mm² for output wiring. Ensure that the input and output terminals are tightly connected to prevent contact resistance from causing overheating. Configure communication parameters (such as GE SRTP address) and protection thresholds (such as over-voltage value) via Mark VIe Configuration Studio. Perform insulation resistance testing (input to ground ≥200MΩ, output to ground ≥200MΩ) and power-on pre-test (verify that both channels output normally) before formal operation.

Maintenance suggestions: Conduct daily remote monitoring of the power status and switchover information of **IS200RAPAG1BBA** via the upper system, focusing on checking whether the output voltage is within the range of 23.2-24.8V DC. Perform monthly on-site inspections: clean the dust on the module radiator, check the tightness of the input/output terminals (torque ≥1.2N·m), and measure the module surface temperature (normal ≤65°C). Test the redundant switchover function quarterly: manually cut off one input power supply and verify that the switchover time is ≤10ms, and the output voltage fluctuation is ≤±0.5V. Perform semi-annual calibration of the output voltage accuracy using a standard multimeter. Conduct annual insulation resistance testing (input to output ≥2000MΩ at 2000V AC) and visual inspection of the power module capacitors. Update the module firmware annually via GE’s local technical support platform to optimize stable operation performance.

Service and Guarantee Commitment

GE General Electric provides a 48-month quality guarantee for the **IS200RAPAG1BBA**, covering manufacturing defects, redundant switchover failures, output voltage instability, protection function abnormalities, and communication interface malfunctions under normal operating conditions. Our technical team offers 8×5 on-site and remote assistance, including power system configuration guidance, basic fault diagnosis, and maintenance training. Customers can obtain standard Mark VIe power configuration tools and module maintenance documents for free during the guarantee period. Priority service customers enjoy 48-hour emergency replacement of faulty modules and on-site technical support services, ensuring minimal downtime for conventional turbine control system power supplies. For large-scale application projects, we provide customized on-site installation and commissioning guidance services.