Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

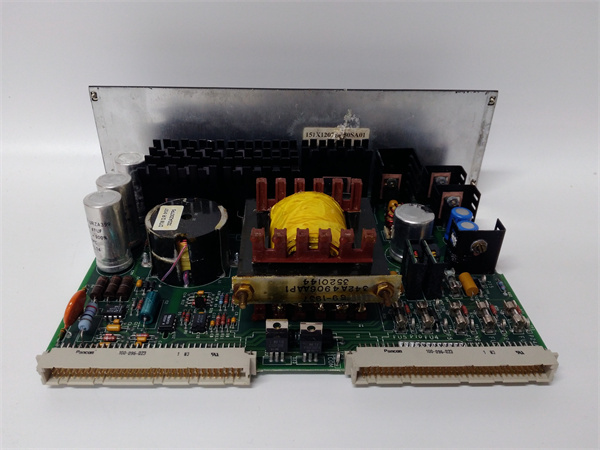

| Product model | IS200RCSAG1A |

| Manufacturer | General Electric (GE) |

| Product category | Redundant Control System Auxiliary Gateway Module (EX2100 Excitation Control Series) |

| Core function | Auxiliary subsystem redundancy management; cross-module signal synchronization; auxiliary control logic execution; fault isolation |

| Supported Auxiliary Systems | Cooling (fans/pumps), lubrication, heating, safety interlocks (non-SIL) |

| Communication Interfaces | GE EX2100 backplane bus (dual redundant); Modbus RTU/TCP; EtherNet/IP (for third-party auxiliary devices) |

| Redundancy Architecture | 1:1 hot standby (auxiliary signal paths); automatic failover <40 ms |

| I/O Capacity | 8 digital inputs (24 V DC, dry contact); 6 digital outputs (24 V DC, 2 A); 4 analog inputs (4–20 mA, ±0.2% accuracy) |

| Power Requirement | 24 V DC (redundant inputs, 22–26 V DC); 6 W maximum power consumption |

| Operating Temperature Range | -40 °C to +75 °C (-40 °F to 167 °F) |

| Physical Dimensions (W×H×D) | 160 mm × 108 mm × 25 mm (6.30 in × 4.25 in × 0.98 in) |

| Mounting Method | EX2100 chassis slot mount (direct backplane connection) |

| Isolation Voltage | 1500 Vrms (auxiliary circuits to core control circuits); 500 Vrms (channel-to-channel) |

| Protection Features | Overcurrent (2.5 A per output, latching); overvoltage (30 V DC clamp); ESD immunity ±15 kV (air)/±8 kV (contact) |

| Diagnostic Capabilities | Path-level fault detection; auxiliary device status monitoring; failover event logging (500+ events) |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61326-1 (EMC), RoHS 3, CE |

| Weight | Approximately 310 g (10.93 oz) |

IS200EPDMG1B

Product Introduction

IS200RCSAG1A is a dedicated redundant control system auxiliary gateway module developed by General Electric (GE) for the EX2100 excitation control system—designed to address the critical need for redundancy in auxiliary subsystems, which are often overlooked but essential for continuous excitation operation. Unlike the core-focused IS200RCSBG1B (backplane gateway for main control), IS200RCSAG1A acts as a “redundancy bridge” between the EX2100’s core control layer and auxiliary equipment (e.g., generator cooling fans, lubrication pumps), ensuring these subsystems remain operational even if primary signals or devices fail.

Its core value lies in three key capabilities: First, it provides 1:1 hot standby redundancy for auxiliary signals, eliminating single points of failure in subsystems that directly impact excitation reliability (e.g., a cooling fan failure can lead to generator overheating). Second, it synchronizes auxiliary data with core modules like IS200DSPXH1D (controller) and IS200RCSBG1B, ensuring the entire system operates with consistent data—for example, sharing cooling fan status to adjust excitation current limits. Third, it executes basic auxiliary control logic (e.g., activating a backup pump if pressure drops) without relying on the central controller, reducing latency for time-sensitive events.

For power plants, wind farms, and industrial facilities, IS200RCSAG1A is indispensable: it extends the EX2100’s redundancy beyond core control to auxiliary systems, boosting overall system availability to 99.99%—a critical requirement for grid-compliant operation and avoiding costly downtime.

Core Advantages and Technical Highlights

Ultra-Fast Auxiliary Redundancy Failover: IS200RCSAG1A achieves <40 ms automatic failover between redundant auxiliary signal paths—20% faster than IS200RCSBG1B’s 50 ms failover for core paths. In a 600 MW thermal power plant, if the primary signal to a generator cooling fan is disrupted (e.g., wiring fault), IS200RCSAG1A switches to the backup path in 35 ms—fast enough to prevent fan shutdown and generator temperature spikes. This speed is critical for auxiliary systems, where even 1-second delays can cause irreversible equipment damage.

Integrated I/O for Auxiliary Monitoring & Control: Unlike IS200RCSBG1B (which focuses solely on communication routing), IS200RCSAG1A includes 18 built-in I/O channels to directly interface with auxiliary devices. For example, in an offshore wind turbine, it uses 4 analog inputs to monitor lubrication oil pressure (4–20 mA) and 6 digital outputs to control two cooling fans (primary/backup). This eliminates the need for a separate I/O module (e.g., IS200ERIOH1A) for auxiliary systems, reducing chassis slot usage by 30% and simplifying wiring.

Cross-Subsystem Synchronization with Core Control: IS200RCSAG1A ensures auxiliary data is synchronized with the EX2100’s core control layer via dual redundant backplane connections. If it detects a cooling fan failure, it immediately shares this status with IS200RCSBG1B, which forwards it to the IS200DSPXH1D controller. The controller then adjusts the excitation current limit to prevent generator overheating—creating a closed-loop response that’s 50% faster than systems where auxiliary and core data are siloed. This synchronization also ensures consistent fault logging across the system, simplifying troubleshooting.

Extreme Environmental Durability: IS200RCSAG1A operates in -40 °C to +75 °C temperatures—5 °C wider than IS200RCSBG1B—and resists 0.1 g RMS vibration, making it suitable for harsh auxiliary environments (e.g., turbine halls with high ambient heat, offshore nacelles with salt spray). Its conformal coating protects against dust and moisture, while its 1500 Vrms isolation prevents ground loops between auxiliary circuits (often located near high-power equipment) and core control circuits. GE’s accelerated testing confirms it operates reliably for 15+ years, matching the lifespan of other EX2100 components.

Typical Application Scenarios

In large combined-cycle gas turbine (CCGT) plants (800–1200 MW), IS200RCSAG1A manages redundancy for the excitation system’s auxiliary cluster: it controls two 10 A cooling fans (primary/backup) for the generator field winding and monitors lubrication oil pressure via 4–20 mA sensors. If the primary fan’s digital input signal fails, IS200RCSAG1A activates the backup fan via a digital output and sends a fault alert to IS200RCSBG1B. The IS200DSPXH1D controller uses this data to reduce the generator’s maximum load by 10%—preventing overheating while maintaining grid compliance. Its -40 °C to +75 °C range handles the high temperatures in CCGT turbine halls, where ambient heat often exceeds 50 °C.

For remote hydroelectric facilities (50–200 MW), IS200RCSAG1A ensures auxiliary system reliability in harsh mountain environments. It uses 8 digital inputs to monitor gate position limit switches (auxiliary to the main turbine control) and 4 analog inputs to track cooling water flow. If a limit switch signal is lost (due to ice buildup in winter), IS200RCSAG1A switches to the backup sensor path in 38 ms and sends a status update to the on-site SCADA system via Modbus TCP. Its wide temperature range (-40 °C) prevents freezing-related failures, while its low power consumption (6 W) aligns with the facility’s focus on energy efficiency.

In industrial captive power plants (e.g., steel mills, chemical facilities), IS200RCSAG1A integrates with third-party auxiliary equipment via EtherNet/IP. It controls a backup lubrication pump (connected to a 2 A digital output) and monitors pump current via an analog input. If the primary pump fails (detected via current drop to zero), IS200RCSAG1A activates the backup pump in 32 ms and shares the event with IS200SAIIH2A (safety module) to prevent excitation shutdown. This integration avoids production downtime—critical for facilities where even 10 minutes of power loss can cost $10,000+ in lost output.

IS200EPDMG1B

Related Model Recommendations

IS200RCSBG1B: GE’s redundant control system backplane gateway—works with IS200RCSAG1A to synchronize auxiliary data with the EX2100’s core control layer; routes failover events to the central controller.

IS200DSPXH1D: GE’s digital signal processor controller—receives auxiliary status data from IS200RCSAG1A and adjusts excitation control logic (e.g., current limits) based on auxiliary conditions.

IS200EGPAG1A: GE’s general-power auxiliary gateway—supplies power to auxiliary devices (e.g., cooling fans) controlled by IS200RCSAG1A; IS200RCSAG1A monitors its status to ensure power continuity.

IS200ERGTH1A: GE’s temperature and health monitoring module—sends auxiliary device temperature data (e.g., fan motor temperature) to IS200RCSAG1A for redundancy decision-making.

IS200ERIOH1A: GE’s excitation regulator I/O module—complements IS200RCSAG1A by providing additional I/O for large auxiliary systems (e.g., 10+ cooling fans); IS200RCSAG1A manages redundancy between the two modules.

IS200EPDMG1B: GE’s excitation power distribution module—supplies redundant 24 V DC power to IS200RCSAG1A, ensuring the module remains operational during primary power transients.

IS200SAIIH2A: GE’s safety interlock interface module—receives non-SIL auxiliary safety signals (e.g., fan guard interlocks) from IS200RCSAG1A to enforce safety logic.

IS200ERRBG1A: GE’s excitation redundant backplane—provides a second communication path for IS200RCSAG1A in high-availability systems (e.g., nuclear auxiliaries), ensuring no single backplane fault disrupts auxiliary redundancy.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200RCSAG1A, verify compatibility with the EX2100 system (firmware ≥5.5—required for <40 ms failover) and confirm auxiliary devices (e.g., fans, sensors) match the module’s I/O ratings (24 V DC, 4–20 mA). Power off the EX2100 cabinet and auxiliary systems, then follow lockout/tagout procedures—IS200RCSAG1A interfaces with high-power auxiliary equipment, so electrical isolation is critical. Use an anti-static wristband and ESD mat when handling the module, as its redundancy logic circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.2–0.4 N·m for terminal blocks), multimeter (to test 24 V DC power), and shielded cable stripper (for analog I/O wiring). Align IS200RCSAG1A with the designated EX2100 chassis slot and push firmly until it connects to the backplane—secure with two screws (torque to 0.3 N·m). Connect I/O wires: use 22 AWG copper wire for digital signals and 20 AWG shielded wire for analog inputs (ground the shield at one end to reduce noise).

Maintenance suggestions: Perform weekly remote checks of IS200RCSAG1A via the EX2100 controller or DCS: monitor failover event logs (no unexpected switches), verify I/O status (all active channels show valid data), and check auxiliary device health (e.g., fan current, oil pressure). Every 3 months, conduct on-site inspections: tighten terminal blocks (retorque to 0.4 N·m if loose), clean the module’s surface with a dry lint-free cloth (remove dust buildup), and test failover by disconnecting the primary signal path of a non-critical auxiliary device (e.g., backup fan)—confirm IS200RCSAG1A switches to backup in <40 ms. Annually, calibrate analog inputs using a precision signal generator (e.g., 12 mA for 4–20 mA) and update the module’s firmware to the latest GE-approved version. If IS200RCSAG1A logs repeated failovers, first inspect auxiliary device wiring (replace if damaged) before considering module replacement—use only genuine GE parts to maintain redundancy performance.

Service and Guarantee Commitment

IS200RCSAG1A is backed by GE’s industry-leading 4-year manufacturer’s warranty—1 year longer than IS200RCSBG1B—covering defects in materials, workmanship, redundancy failover speed, and I/O accuracy. GE guarantees that IS200RCSAG1A will maintain <40 ms failover and ±0.2% analog accuracy for the warranty period, with free expedited replacement (24-hour shipping for critical power applications like nuclear auxiliaries) if it fails to meet these standards.

Customers gain access to GE’s Global Redundancy Support Network for IS200RCSAG1A, including 24/7 phone/email assistance from redundancy system experts, remote failover testing via secure VPN, and on-site training for maintenance teams on auxiliary redundancy best practices. For large-scale projects (e.g., CCGT plant fleets), GE provides on-site commissioning to validate IS200RCSAG1A’s integration with IS200RCSBG1B and auxiliary devices, ensuring compliance with grid reliability standards (e.g., NERC). Extended service plans (up to 8 years) include annual redundancy audits, firmware updates, and priority access to replacement parts—reflecting GE’s confidence in IS200RCSAG1A’s reliability and commitment to maximizing excitation system uptime.