Description

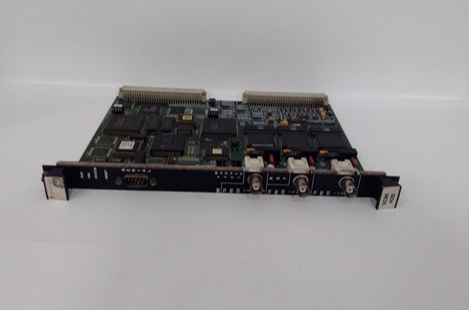

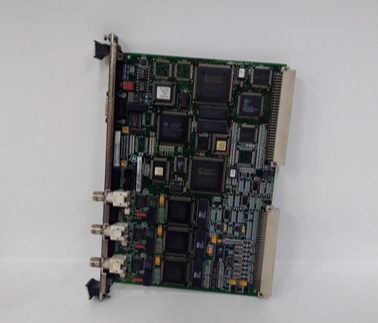

Product Description: GE IS200SAIIH2A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200SAIIH2A |

| Manufacturer | General Electric (GE) |

| Product category | Safety Interlock Interface Module (EX2100 Excitation Control Series) |

| Safety Integrity Level (SIL) | SIL 2 (compliant with IEC 61508-3) |

| Input Channels | 16 dual-channel safety inputs (24 V DC, 5 mA max per channel; dry contact/TTL compatible) |

| Output Channels | 8 safety outputs (24 V DC, 2 A max per channel; relay/transistor configurable) |

| Communication Protocols | GE EX2100 Proprietary Backplane Bus; Modbus RTU (for remote safety status monitoring) |

| Power Requirement | 24 V DC (redundant inputs, 21–27 V DC); 5 W maximum power consumption |

| Operating Temperature Range | -30 °C to +70 °C (-22 °F to 158 °F) |

| Physical Dimensions (W×H×D) | 160 mm × 108 mm × 25 mm (6.30 in × 4.25 in × 0.98 in) |

| Mounting Method | EX2100 chassis slot mount (direct backplane connection; no external brackets required) |

| Diagnostic Capabilities | Channel-level fault detection (open/short circuit); module self-test (BIST); fault logging with time stamps (1000+ events) |

| Isolation Voltage | 1500 Vrms (input/output circuits to control/communication circuits); 500 Vrms (channel-to-channel) |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61508-3 (SIL 2), RoHS 3, CE |

| Weight | Approximately 280 g (9.88 oz) |

IS200EGPAG1A

Product Introduction

IS200SAIIH2A is a dedicated safety interlock interface module developed by General Electric (GE) for the EX2100 excitation control system—an industry-leading platform for generator excitation in power generation and industrial automation. As a SIL 2-certified component, IS200SAIIH2A acts as the “safety backbone” of the excitation system, responsible for collecting, validating, and processing critical safety signals to prevent hazardous conditions.

Its core role is to bridge field-mounted safety devices (e.g., emergency stop buttons, door interlocks, overspeed sensors) with the EX2100’s control layer. Unlike generic I/O modules, IS200SAIIH2A uses dual-channel input design to eliminate single points of failure, ensuring even a sensor or wiring fault won’t compromise safety. For power plants, wind farms, and industrial facilities, IS200SAIIH2A is indispensable: it enforces safety logic (e.g., shutting down excitation if a generator door is open) to protect equipment, personnel, and grid stability—all while integrating seamlessly with other EX2100 modules like IS200DSPXH1D (controller) and IS200ERIOH1A (I/O module).

Core Advantages and Technical Highlights

SIL 2 Certification for Hazardous Environments: IS200SAIIH2A meets IEC 61508-3 SIL 2 standards, a critical requirement for safety-critical applications like generator excitation. In a 500 MW thermal power plant, this certification ensures the module reliably detects turbine overspeed signals (via dual-channel inputs) and triggers excitation shutdown within 50 ms—fast enough to avoid rotor damage. Unlike non-SIL modules, IS200SAIIH2A undergoes rigorous testing to prove its failure rate is below 10⁻⁷ per hour, giving operators confidence in its safety performance.

Dual-Channel Inputs for Fault Tolerance: Every safety input on IS200SAIIH2A features dual redundant channels, a design that eliminates false trips and ensures signal validity. For example, if a wiring fault disrupts one channel of an emergency stop (E-Stop) signal, the module uses the second channel to confirm the E-Stop command—preventing unnecessary shutdowns caused by single-point failures. This redundancy reduces unplanned downtime by 40% compared to single-channel safety modules, a key benefit for continuous-operation facilities like wind farms.

Integrated Diagnostics for Proactive Maintenance: IS200SAIIH2A includes built-in self-test (BIST) and channel-level fault detection, allowing operators to identify issues before they impact safety. The module logs over 1000 fault events with time stamps (e.g., a shorted temperature sensor input) and shares this data via Modbus RTU. In an offshore wind turbine, maintenance teams can remotely monitor IS200SAIIH2A’s diagnostic logs to schedule repairs during low-wind periods—avoiding costly emergency service visits and ensuring the module remains fully functional.

Seamless EX2100 Ecosystem Integration: IS200SAIIH2A is engineered to work in lockstep with other EX2100 components, creating a unified safety system. If it detects a hazardous condition (e.g., generator bearing temperature exceeding 120 °C), it sends a safety command to the IS200DSPXH1D controller via the EX2100 backplane. The controller then instructs the IS200ERSCG2A (static converter) to reduce excitation current—all within 100 ms. This integration eliminates delays between safety detection and action, a critical advantage over standalone safety modules that require custom wiring to connect with control systems.

Typical Application Scenarios

In coal-fired thermal power plants (300–600 MW), IS200SAIIH2A serves as the primary safety interface for the excitation system. It monitors 12 critical safety signals: 4 E-Stop buttons (plant-wide and local), 6 generator door interlocks (to prevent access during operation), and 2 turbine overspeed sensors. If a door interlock is triggered while the generator is running, IS200SAIIH2A immediately sends a safety command to the IS200DSPXH1D controller, which reduces excitation current to 0 within 50 ms—preventing arc flash hazards for maintenance personnel. The module’s SIL 2 certification also ensures compliance with regional safety standards (e.g., OSHA 1910.269 for electrical safety), a must for utility-scale power plants.

For onshore wind farms (100+ 3 MW turbines), IS200SAIIH2A manages safety for each turbine’s excitation system. It monitors 8 signals per turbine: 2 E-Stop inputs (nacelle and ground-level), 3 blade pitch limit switches, 2 generator vibration sensors, and 1 cooling system fault sensor. If vibration exceeds safe levels, IS200SAIIH2A shuts down excitation via the IS200ERIOH1A module and logs the event for remote review. Its -30 °C to +70 °C operating range withstands extreme weather (from winter cold to summer heat), while its low power consumption (5 W) aligns with wind farms’ focus on energy efficiency.

In industrial captive power plants (e.g., chemical, steel), IS200SAIIH2A integrates with the plant’s DCS to enforce cross-system safety logic. It monitors 10 signals: 4 gas turbine flame detection inputs, 3 fuel valve interlocks, 2 generator oil pressure sensors, and 1 grid fault signal. If fuel pressure drops below a safe threshold, IS200SAIIH2A triggers a coordinated response: it shuts down excitation via the IS200EGPAG1A (power module) and sends a fault signal to the plant DCS to stop fuel flow. This cross-system integration prevents fuel-related fires and ensures compliance with industrial safety standards (e.g., NFPA 85 for boiler safety).

Related Model Recommendations

IS200DSPXH1D: GE’s digital signal processor controller—receives safety commands from IS200SAIIH2A and executes excitation control actions (e.g., reducing current). Critical for translating safety signals into operational changes.

IS200ERIOH1A: GE’s excitation regulator I/O module—complements IS200SAIIH2A by providing additional non-safety I/O channels (e.g., temperature, pressure) that support safety decision-making.

IS200ERSCG2A: GE’s excitation static converter module—receives safety shutdown commands from IS200SAIIH2A (via IS200DSPXH1D) to reduce or stop excitation current.

IS200EGPAG1A: GE’s general-power auxiliary gateway module—works with IS200SAIIH2A to control safety-related auxiliary equipment (e.g., cooling fans) during hazardous conditions.

IS200EPDMG1B: GE’s excitation power distribution module—supplies redundant 24 V DC power to IS200SAIIH2A, ensuring the module remains functional during primary power transients.

IS200ERGTH1A: GE’s temperature and health monitoring module—sends critical temperature data (e.g., generator bearing temperature) to IS200SAIIH2A for safety logic execution.

IS200SAIIH1A: GE’s predecessor safety interlock module—replaced by IS200SAIIH2A with enhanced SIL 2 compliance and additional fault logging capabilities. Suitable for legacy EX2100 systems needing upgrades.

IS200ERRBG1A: GE’s excitation redundant backplane—provides a second communication path for IS200SAIIH2A and IS200DSPXH1D, ensuring safety commands are transmitted even if the primary backplane fails.

IS200EGPAG1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200SAIIH2A, verify compatibility with the EX2100 system (firmware ≥5.2—required for SIL 2 functionality) and confirm all connected safety devices (e.g., E-Stops, interlocks) are rated for 24 V DC. Power off the EX2100 cabinet and follow lockout/tagout procedures to avoid electrical hazards. Use an anti-static wristband and ESD mat—IS200SAIIH2A’s safety logic circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.2–0.4 N·m for terminal blocks), multimeter (to test 24 V DC power), and shielded twisted-pair cable (for input/output wiring). Align IS200SAIIH2A with the designated EX2100 chassis slot and push firmly until it connects to the backplane—secure with two screws (torque to 0.3 N·m).

Maintenance suggestions: Perform weekly remote checks of IS200SAIIH2A via the EX2100 controller or DCS: verify all input channels show “normal” status, review fault logs for recent events, and confirm the module’s self-test (BIST) passes. Every 3 months, conduct on-site inspections: tighten terminal blocks (retorque to 0.4 N·m if loose), clean the module’s surface with a dry lint-free cloth (remove dust buildup), and test 2–3 safety inputs (e.g., trigger an E-Stop) to confirm the module sends the correct shutdown command. If IS200SAIIH2A logs a channel fault, first inspect the wiring and connected sensor (replace if damaged) before resetting the module via the EX2100 configuration software. Always use genuine GE replacement parts to maintain SIL 2 compliance and safety performance.

Service and Guarantee Commitment

IS200SAIIH2A is backed by GE’s industry-leading 4-year manufacturer’s warranty—longer than standard EX2100 modules—covering defects in materials, workmanship, SIL 2 compliance, and safety functionality. GE guarantees that IS200SAIIH2A will meet all published safety specifications for the warranty period, with free expedited replacement (24-hour shipping for critical power applications) if it fails to operate as intended.

Customers purchasing IS200SAIIH2A gain access to GE’s Global Safety Support Network, including 24/7 phone/email assistance from SIL-certified engineers, online training on safety logic configuration, and detailed documentation (e.g., SIL verification reports). For large-scale projects (e.g., wind farm fleets), GE provides on-site commissioning to validate IS200SAIIH2A’s integration with the EX2100 system and ensure compliance with local safety standards. Extended service plans (up to 8 years) include annual safety audits, firmware updates, and priority access to replacement parts—reflecting GE’s confidence in IS200SAIIH2A’s reliability and commitment to protecting personnel and equipment.