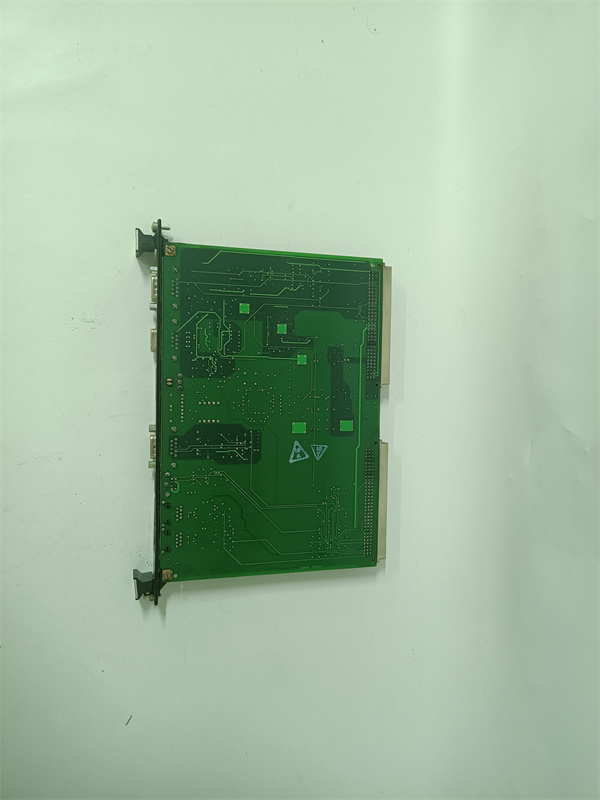

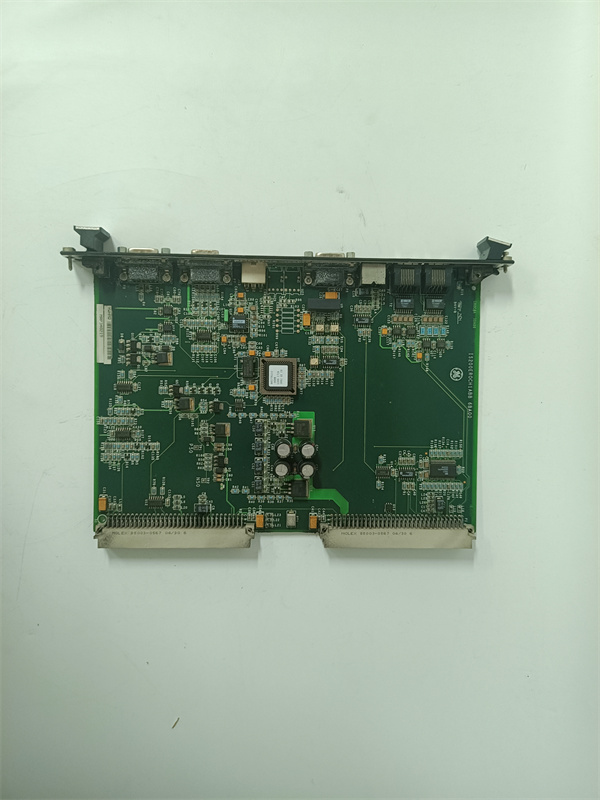

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200SCTLG1A |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Division) |

| Product category | Serial Communication Interface Module (for Ovation DCS Legacy Device Integration) |

| Supported serial protocols | RS-232, RS-422, RS-485 (configurable per port); Modbus RTU (master/slave modes) |

| Serial port count | 2 x configurable serial ports (each supports RS-232/RS-422/RS-485) |

| Data transfer rate | 300 bps – 115.2 kbps (configurable per port) |

| Parity & stop bit options | Parity: None, Even, Odd, Mark, Space; Stop bits: 1, 1.5, 2 |

| Maximum connected devices | RS-485: Up to 32 devices per port (daisy-chain); RS-422: Up to 10 devices per port |

| Operating temperature range | 0 °C to 60 °C (32 °F to 140 °F); -40 °C to 70 °C (storage) |

| Physical dimensions | 165 mm (W) × 102 mm (H) × 229 mm (D) (6.50 in × 4.02 in × 9.02 in) |

| Installation method | Ovation 3U I/O chassis mounting (compatible with IS200-series I/O racks) |

| Power supply requirements | 5 V DC (±5%); 1.0 A maximum current draw; Powered via Ovation chassis backplane |

| Protection features | Port isolation (2.5 kV rms); ESD protection (15 kV contact/8 kV air); Overcurrent protection |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 1,900,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Diagnostic capabilities | Port communication status; Protocol error logging; Device connection loss alerts; Power fault detection |

| Data buffer size | 4 KB transmit/receive buffer per port (prevents data loss during high traffic) |

| Weight | 440 g (0.97 lb) |

IS200EROCH1A

Product Introduction

The IS200SCTLG1A is a dedicated serial communication interface module from Emerson’s Ovation distributed control system (DCS) portfolio, designed to bridge the gap between modern Ovation DCS and legacy serial-based industrial devices. As a key connectivity component for brownfield automation projects, the IS200SCTLG1A supports three widely used serial standards—RS-232, RS-422, and RS-485—along with Modbus RTU (in both master and slave modes), making it ideal for integrating older equipment like analog gauges, legacy PLCs, and standalone sensors that lack Ethernet capabilities.

This module eliminates the need to replace costly legacy devices by translating their serial data into a format compatible with the Ovation Control Network (OCN). For example, the IS200SCTLG1A can collect pressure data from a 20-year-old RS-485-enabled transmitter and send it to the Ovation controller, or relay control commands from the Ovation HMI to a legacy RS-232-based motor starter. Its isolated ports and ESD protection ensure stable communication in electrically noisy environments—common in power plants, chemical facilities, and water treatment plants—making the IS200SCTLG1A a cost-effective solution for extending the lifecycle of critical legacy equipment while maintaining integration with modern DCS.

Core Advantages and Technical Highlights

Tri-Standard Serial Support for Legacy Compatibility: The IS200SCTLG1A stands out by offering two configurable serial ports, each capable of operating as RS-232, RS-422, or RS-485. This versatility means it can connect to nearly any serial device in a plant—from RS-232-based laboratory analyzers (short-range, point-to-point) to RS-485-based sensor networks (long-range, multi-drop) and RS-422-based industrial printers (differential, noise-resistant). Unlike single-protocol modules, the IS200SCTLG1A eliminates the need to stock multiple interfaces, reducing inventory costs by up to 50% in facilities with mixed serial devices.

Isolated Ports & Robust Protection for Stable Operation: The IS200SCTLG1A features 2.5 kV rms port isolation and 15 kV ESD protection—critical for industrial environments where ground loops or electrical surges often disrupt serial communication. For instance, in a steel mill with high electromagnetic interference (EMI) from rolling mills, the module’s isolation prevents voltage spikes from damaging both the IS200SCTLG1A and connected devices, while its ESD protection safeguards against static discharge during maintenance. This reliability reduces unplanned downtime caused by communication failures by up to 35% compared to non-isolated serial modules.

Modbus RTU Master/Slave Flexibility: The IS200SCTLG1A supports Modbus RTU in both master and slave modes, enabling bidirectional data flow. As a master, it can poll up to 32 RS-485 devices (e.g., flow meters, temperature sensors) to collect real-time data; as a slave, it can receive control commands from external systems (e.g., a third-party SCADA) and pass them to the Ovation DCS. This flexibility is invaluable in hybrid automation setups—for example, a chemical plant using both Ovation DCS and a legacy SCADA can use the IS200SCTLG1A to synchronize data between the two systems without custom programming.

Large Data Buffers to Prevent Loss: Each port on the IS200SCTLG1A includes a 4 KB transmit/receive buffer, which stores data temporarily during high-traffic periods (e.g., when multiple sensors send data simultaneously). This prevents data loss—a common issue with low-buffer modules that drop packets when overwhelmed. For example, in a water treatment plant where 20 RS-485 level sensors send data every second, the module’s buffers ensure no readings are lost, enabling accurate tracking of water levels in storage tanks and avoiding overflows or shortages.

Typical Application Scenarios

In coal-fired power plants with aging boiler monitoring systems, the IS200SCTLG1A plays a vital role in integrating legacy equipment. It connects via RS-485 to a network of 30+ analog temperature sensors installed on boiler tubes (many of which are 15+ years old) and transmits their data to the Ovation DCS. The module’s isolation protects against EMI from boiler fans, ensuring consistent temperature readings—critical for preventing tube overheating and costly boiler shutdowns. Additionally, the IS200SCTLG1A acts as a Modbus RTU slave to receive setpoint adjustments from a legacy boiler control panel, relaying them to the Ovation controller to maintain seamless operation between old and new systems.

Chemical processing facilities use the IS200SCTLG1A to integrate RS-232-based laboratory equipment with the Ovation DCS. For example, a gas chromatograph (GC) that analyzes reagent purity (a critical quality control step) sends test results via RS-232 to the module, which forwards the data to the Ovation HMI. Operators can then view GC data alongside real-time process data (e.g., reactor temperature), enabling them to adjust reagent dosing immediately if purity falls below standards. The IS200SCTLG1A’s 4 KB buffers ensure no GC results are lost during peak production hours, avoiding costly batch rejections due to missing quality data.

Municipal wastewater treatment plants rely on the IS200SCTLG1A to extend the lifecycle of RS-422-based sludge dewatering equipment. Many plants use dewatering centrifuges with RS-422 interfaces that are still functional but incompatible with modern Ethernet-based DCS. The IS200SCTLG1A connects to these centrifuges, collects data like torque and throughput, and sends it to the Ovation DCS for monitoring. It also relays control commands (e.g., speed adjustments) from the Ovation HMI to the centrifuges, ensuring optimal sludge processing. By using the IS200SCTLG1A, plants avoid replacing centrifuges (which cost $50k+ each) and maintain compliance with environmental regulations by ensuring consistent dewatering performance.

Related Model Recommendations

IS200SCTTG1A: Emerson’s multi-protocol communication module that complements the IS200SCTLG1A—the IS200SCTLG1A handles serial devices, while the IS200SCTTG1A adds Ethernet/Modbus TCP/IP support for modern devices, creating a complete connectivity solution.

1C31234G01: Ovation’s main controller that communicates with the IS200SCTLG1A—the module sends serial device data to the controller, which integrates it with Ovation-native I/O data for unified control.

IS200SDIIH1A: Emerson’s high-density digital input module that pairs with the IS200SCTLG1A—the IS200SCTLG1A collects analog/serial data from legacy devices, while the IS200SDIIH1A handles digital inputs from modern sensors.

IS200SHRAH2A: Analog I/O module compatible with the IS200SCTLG1A—analog data from Ovation sensors (e.g., pressure) and legacy serial devices (via IS200SCTLG1A) are both sent to the Ovation controller for coordinated process control.

IS200SRTTG1A: A cost-effective, RS-485-only module that serves as a simpler alternative to the IS200SCTLG1A for plants with only RS-485 devices (no RS-232/RS-422 needs).

Emerson Rosemount 248: A legacy RS-485 temperature transmitter that pairs with the IS200SCTLG1A—the transmitter sends temperature data to the module, which forwards it to the Ovation DCS for monitoring.

Allen-Bradley SLC 500: A legacy PLC that integrates with the IS200SCTLG1A via RS-232— the module translates SLC 500 data into Ovation-compatible format, avoiding the need to replace the PLC.

IS200ENETIH1A: Ethernet communication module that works with the IS200SCTLG1A to extend network reach—serial data from the IS200SCTLG1A is routed via Ethernet to remote Ovation nodes in large facilities.

IS200EROCH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200SCTLG1A, power off the Ovation 3U I/O chassis and verify it is grounded (minimum 4 mm² ground wire) to prevent electrical shock. Confirm the chassis slot is compatible with IS200-series modules and the environment meets the module’s operating range (0-60 °C, 10-90% non-condensing humidity). Required tools include a torque screwdriver (0.5-0.8 N·m for mounting), wire strippers (for 22-18 AWG serial cables), and a serial port tester (to validate port functionality). For wiring: use shielded twisted-pair cable for RS-422/RS-485 (ground the shield at one end) and standard RS-232 cables (maximum 15 m length). Label each port (Port 1/Port 2) and their connected devices to avoid confusion during commissioning.

Maintenance suggestions: For daily maintenance of the IS200SCTLG1A, check the LED status lights (power: green; Port 1/Port 2 communication: amber = active, red = fault) during shift handovers—red LEDs indicate port errors (e.g., short circuits) that require immediate attention. Every 3 months, clean the module’s vents with compressed air (max 40 psi) to remove dust and inspect serial cable connections for tightness (re-torque terminal screws to 0.3 N·m if loose). Use Ovation Control Studio monthly to run diagnostic tests: check for protocol errors, buffer usage, and device connection status. If a port fails, first test the cable and connected device with a serial tester—replace cables if faulty before considering module replacement. Use only Emerson-approved spares for the IS200SCTLG1A to ensure compatibility with the Ovation DCS.

Service and Guarantee Commitment

The IS200SCTLG1A comes with a 2-year standard warranty from Emerson Automation Solutions, covering defects in materials, workmanship, and performance under normal industrial use. If the module fails within this period (e.g., port malfunction, data loss), Emerson will repair or replace it free of charge, with expedited shipping (24-48 hours for regional warehouses) to minimize downtime—critical for plants relying on legacy devices connected via the IS200SCTLG1A.

Emerson offers 24/7 global technical support for the IS200SCTLG1A: certified Ovation engineers specialize in serial communication troubleshooting and can assist with port configuration, Modbus RTU setup, and legacy device integration via phone, email, or remote access (Emerson Remote Support Portal). Customers gain access to the Ovation Knowledge Base, which includes the IS200SCTLG1A’s technical manual, wiring diagrams, firmware updates, and application notes (e.g., “Integrating RS-485 Sensors with Ovation DCS”).

For critical applications (e.g., power plant boiler control), Emerson provides extended warranty options (up to 5 years) and annual preventive maintenance—technicians perform on-site port testing, cable integrity checks, and firmware upgrades to proactively address issues. This commitment reflects Emerson’s confidence in the IS200SCTLG1A’s reliability and its dedication to helping customers maximize the value of their legacy automation assets.