Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

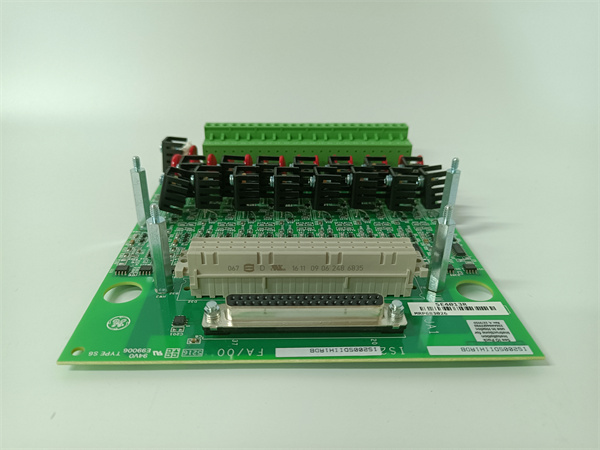

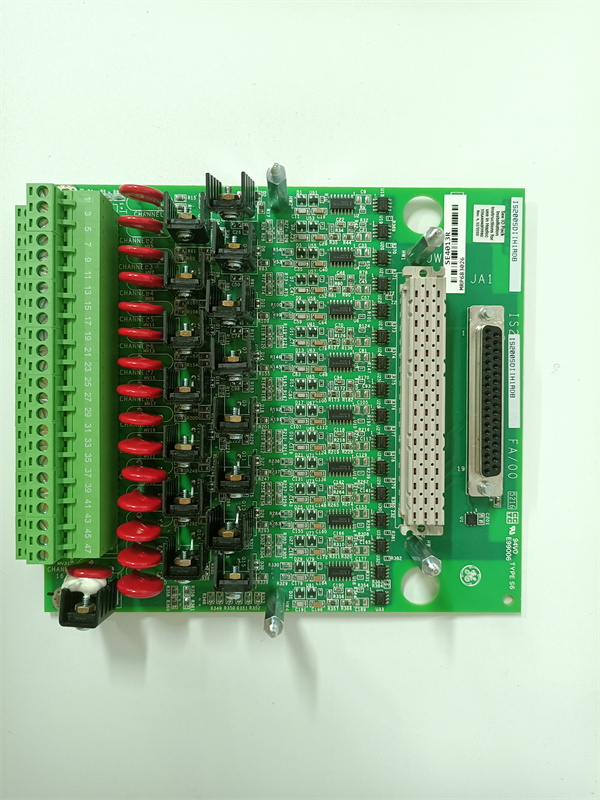

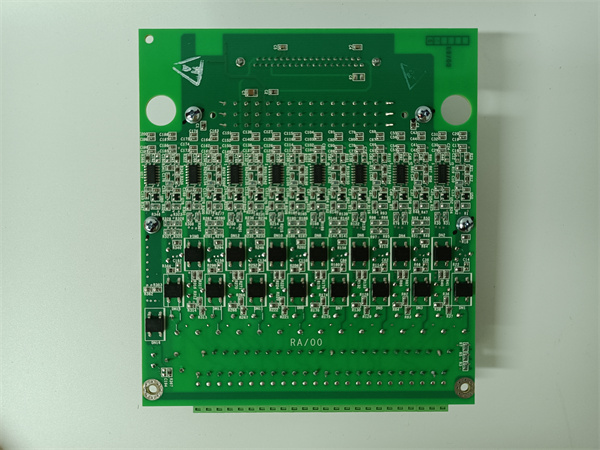

| Product model | IS200SDIIH1A |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Division) |

| Product category | High-Density Discrete Digital Input Module (for Industrial DCS) |

| Input channel count | 32 differential digital input channels (configurable per group of 8) |

| Input signal type | Dry contact (NO/NC); 24 V DC sinking/sourcing (configurable) |

| Input voltage range | 18 V DC to 32 V DC (nominal 24 V DC) |

| Input current | 3 mA to 10 mA (per channel, at 24 V DC) |

| Response time | ≤1 ms (typical); ≤2 ms (maximum) for signal detection |

| Communication protocol | Ovation Control Network (OCN); Redundant data bus support (A/B channels) |

| Operating temperature range | 0 °C to 60 °C (32 °F to 140 °F); -40 °C to 70 °C (storage) |

| Physical dimensions | 165 mm (W) × 102 mm (H) × 229 mm (D) (6.50 in × 4.02 in × 9.02 in) |

| Installation method | Ovation 3U I/O chassis mounting (compatible with IS200 I/O racks) |

| Protection features | Channel-level short-circuit protection; overvoltage protection (up to 36 V DC) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 1,800,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Diagnostic capabilities | Channel open/short detection; power supply monitoring; bus communication status |

| Weight | 480 g (1.06 lb) |

IS200SDIIH1A

Product Introduction

The IS200SDIIH1A is a high-density digital input module from Emerson’s Ovation distributed control system (DCS) lineup, engineered to efficiently collect discrete signals from hundreds of field devices in industrial processes. As a core I/O component of the Ovation platform, the IS200SDIIH1A integrates 32 configurable differential input channels—double the density of standard 16-channel modules—enabling significant space savings in control cabinets while reducing wiring complexity.

This module converts dry contact signals (e.g., from limit switches, pushbuttons, or valve position sensors) and 24 V DC discrete signals into digital data for the Ovation controller, forming the “sensory network” of automation systems. The IS200SDIIH1A’s fast response time (≤1 ms) ensures real-time detection of critical state changes—such as a sudden valve closure or motor stop—while its redundant OCN communication ensures data is never lost. Whether in power generation, chemical processing, or water treatment, the IS200SDIIH1A serves as a reliable interface between field devices and centralized control, laying the foundation for safe and efficient operation.

Core Advantages and Technical Highlights

32-Channel High Density for Space Optimization: The IS200SDIIH1A’s 32 differential input channels eliminate the need for multiple low-density modules—for a system requiring 128 digital inputs, only 4 IS200SDIIH1A modules are needed (vs. 8 standard 16-channel modules). This reduces I/O chassis space by 50% and cuts wiring labor by 30%, a critical advantage in large-scale projects like coal-fired power plants (which often require thousands of discrete inputs for boiler and turbine monitoring).

Dual-Configurable Input Flexibility: Unlike fixed-type digital input modules, the IS200SDIIH1A supports both dry contact (NO/NC) and 24 V DC sinking/sourcing signals, with configuration possible per group of 8 channels. For example, in a chemical plant, 8 channels can be set to monitor dry-contact valve position switches, while another 8 channels handle 24 V DC level sensor signals—all via a single IS200SDIIH1A module. This flexibility eliminates the need to stock multiple module types, reducing inventory costs.

Ultra-Fast Response Time for Critical Control: With a typical response time of ≤1 ms, the IS200SDIIH1A detects signal changes almost instantaneously—critical for safety interlock systems (e.g., emergency shutdowns in oil refineries). If a pressure relief valve opens unexpectedly, the module transmits the signal to the Ovation controller in under 1 ms, enabling the controller to trigger corrective actions (e.g., shutting down a feed pump) before a hazardous situation escalates. This speed outperforms many competitors’ modules (which often have 5-10 ms response times).

Comprehensive Diagnostics & Redundancy: The IS200SDIIH1A includes channel-level diagnostics that detect open circuits (e.g., a broken wire to a sensor) and short circuits (e.g., a water leak causing signal shorting), with alerts sent directly to the Ovation HMI. Its redundant OCN communication (A/B data buses) ensures no single bus failure disrupts data transmission, while overvoltage protection (up to 36 V DC) shields the module from transient voltage spikes common in industrial grids. These features minimize unplanned downtime by enabling proactive maintenance and fault isolation.

Typical Application Scenarios

In combined-cycle power plants, the IS200SDIIH1A is a workhorse for turbine and heat recovery steam generator (HRSG) monitoring. It collects signals from 32 discrete devices per module—including turbine bearing temperature switches, HRSG water level switches, and fuel valve position sensors—transmitting data to the Ovation controller for real-time oversight. The module’s high density reduces the number of I/O chassis needed in the turbine control room, while its fast response time ensures the controller detects issues like a stuck fuel valve within 1 ms, preventing turbine damage.

Chemical processing facilities use the IS200SDIIH1A to monitor batch reactor safety systems. It tracks signals from emergency stop buttons, pressure relief valve contacts, and door interlocks (to prevent access to hazardous areas during reaction). The module’s differential input design eliminates noise interference from nearby motor cables, ensuring accurate signal detection even in electrically noisy environments (e.g., near large mixers). If a reactor door is opened prematurely, the IS200SDIIH1A sends an immediate signal to the Ovation controller, which pauses the reaction and activates alarms—complying with OSHA and EPA safety standards.

Municipal wastewater treatment plants rely on the IS200SDIIH1A to monitor pump stations and filtration systems. It collects signals from pump start/stop contacts, filter clog switches, and gate valve position sensors across 32 channels. The module’s diagnostic capabilities alert operators to a broken sensor wire before it causes a pump failure, while its compatibility with Ovation’s Plantweb digital ecosystem enables remote monitoring via mobile devices. In remote pump stations with limited cabinet space, the IS200SDIIH1A’s high density eliminates the need for additional I/O racks, reducing installation costs.

Related Model Recommendations

IS200SDIOH1A: A sibling module of the IS200SDIIH1A with 32 digital output channels (vs. inputs), ideal for pairing with the IS200SDIIH1A to create a complete input-output loop (e.g., monitoring valve position via IS200SDIIH1A and controlling the valve via IS200SDIOH1A).

IS200SHRAH2A: Emerson’s analog I/O module (8 inputs, 4 outputs) that complements the IS200SDIIH1A in mixed-signal systems—for example, using IS200SDIIH1A for discrete valve status and IS200SHRAH2A for analog flow rate data in a chemical reactor.

1C31234G01: Ovation’s main controller that communicates directly with the IS200SDIIH1A to process digital input data and execute control logic, forming the core of the Ovation DCS.

IS200ENETIH1A: An Ethernet communication module that extends the IS200SDIIH1A’s connectivity, enabling data transmission to cloud-based platforms (e.g., Emerson Plantweb Optics) for remote monitoring and analytics.

IS200TBAIH1B: A 16-channel digital input module that serves as a smaller alternative to the IS200SDIIH1A for low-density applications (e.g., small pump stations requiring <16 discrete inputs).

IS200VCRLY1A: A relay output module that works with the IS200SDIIH1A to control high-power devices (e.g., large motors) — the IS200SDIIH1A monitors motor overload contacts, while IS200VCRLY1A triggers motor shutdowns.

IS200SDIIH2A: An upgraded variant of the IS200SDIIH1A with enhanced diagnostic capabilities (e.g., temperature drift monitoring) and -40 °C to 70 °C operating range, for extreme environments like arctic oil fields.

Ovation 3500/22: A vibration monitoring module that integrates with the IS200SDIIH1A in rotating machinery applications (e.g., power plant turbines) — the IS200SDIIH1A monitors bearing temperature switches, while the 3500/22 tracks vibration levels.

IS200SDIIH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200SDIIH1A, ensure the Ovation 3U I/O chassis is powered off and grounded per Emerson’s guidelines (minimum 4 mm² ground wire). Verify the chassis slot is compatible with Ovation IS200-series modules and the environment meets the module’s operating temperature (0-60 °C) and humidity (10-90%, non-condensing) requirements. Required tools include a torque screwdriver (for module mounting, torque setting: 0.5-0.8 N·m), wire strippers (for 18-22 AWG signal wires), and a multimeter (to test input voltage). Use twisted-pair shielded cables for wiring to minimize EMI interference, and label each channel (1-32) to avoid cross-connection errors. Always disconnect power to the I/O chassis before inserting the IS200SDIIH1A to prevent damage.

Maintenance suggestions: For daily maintenance of the IS200SDIIH1A, check the module’s LED status lights (power: green, communication: amber, channel fault: red) during shift handovers—red LEDs indicate channel-level issues (e.g., short circuits). Calibrate the module’s input detection thresholds annually using Emerson’s Ovation Control Studio software to maintain response time accuracy. Every 6 months, inspect wiring terminals for tightness (re-torque to 0.3 N·m if loose) and clean the module’s vents with compressed air (max 40 psi) to remove dust. If a channel fault occurs, use the Ovation HMI’s diagnostic tool to isolate the issue (e.g., open circuit on channel 12) before replacing wires or the IS200SDIIH1A. Use only Emerson-approved spare modules to ensure compatibility and safety compliance.

Service and Guarantee Commitment

The IS200SDIIH1A comes with a 2-year standard warranty from Emerson Automation Solutions, covering defects in materials, workmanship, and performance under normal industrial use. If the module fails within this period (e.g., channel malfunction or communication failure), Emerson will repair or replace it free of charge, with expedited shipping (24-48 hours for regional warehouses) to minimize operational downtime—critical for power plants or chemical facilities where I/O module failures can disrupt production.

Emerson offers 24/7 global technical support for the IS200SDIIH1A: certified Ovation engineers provide assistance via phone, email, or remote access (through Emerson’s Remote Support Portal) to resolve installation, configuration, or troubleshooting issues. Customers gain access to the Emerson Ovation Knowledge Base, which includes the IS200SDIIH1A’s technical manual, wiring diagrams, firmware updates, and training videos to optimize module performance.

For mission-critical applications (e.g., nuclear power plant safety systems), Emerson provides extended warranty options (up to 5 years) and annual preventive maintenance services—trained technicians perform on-site module testing, calibration, and firmware upgrades to proactively address potential issues. This commitment reflects Emerson’s confidence in the IS200SDIIH1A’s reliability and its dedication to helping customers maintain uninterrupted DCS operation.